Q550 Steel | High Strength Structural Steel

Q550 Steel | High Strength Structural Steel

Q550 is a high-strength structural steel used in China. “Q” indicates yield strength, and “550” means 550 MPa. Equivalent grades are S550MC and A572 Grade 65. It offers high strength, toughness, and weldability, suitable for heavy machinery, structural parts, bridges, vehicle frames, and high-stress equipment.

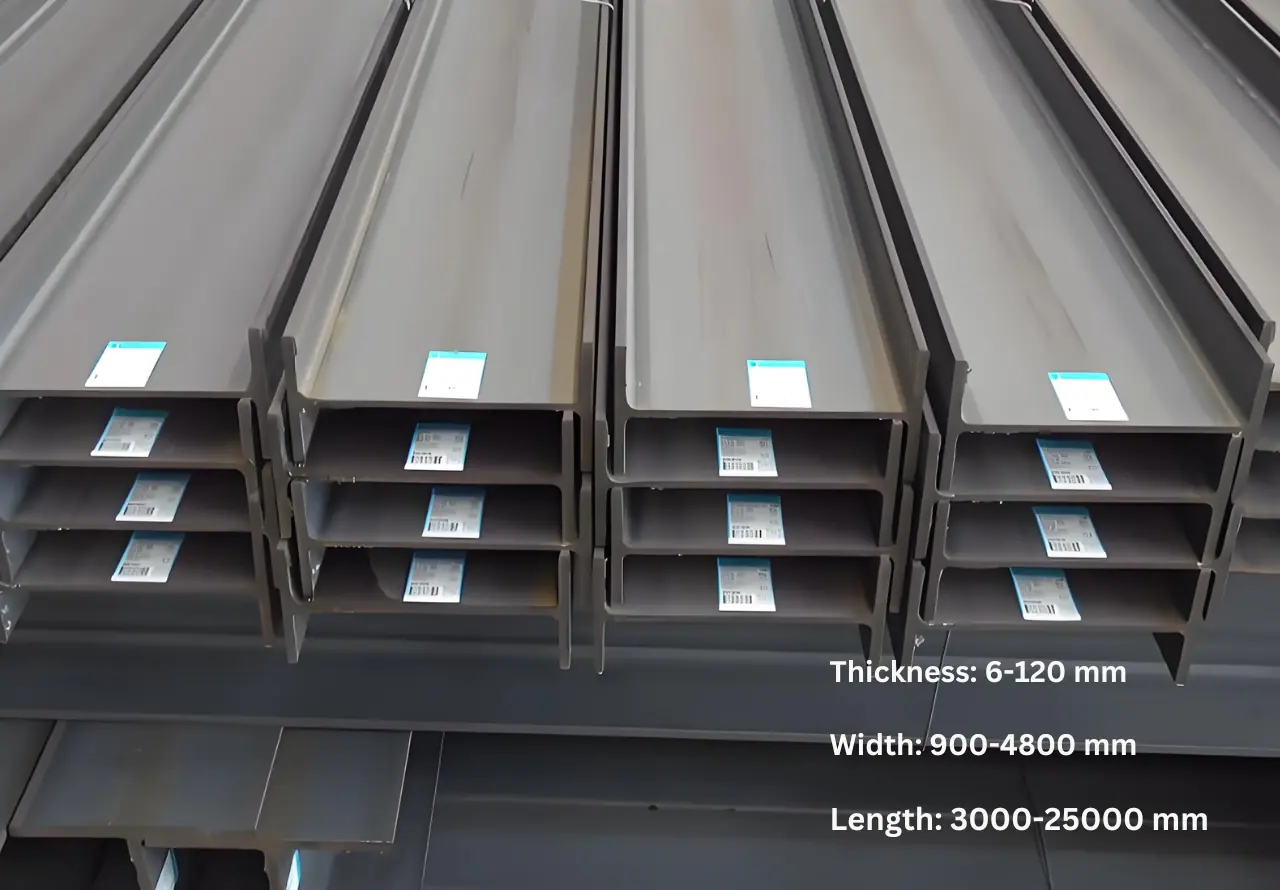

We can provide Q550C/D/E products ranging from 6 to 120mm thicknesses, 900~4800 mm width, and 3000~25000 mm length according to the GB/T 1591 standard.

Description

What is Q550 Steel?

Q550 is a high-strength low-alloy structural steel made of around 98% iron with small amounts of carbon, manganese, and other alloying elements. It is typically produced as solid plates or sheets and processed through hot rolling. Q550 offers excellent strength, toughness, and good weldability. It can be further classified into Q550C, Q550D, and Q550E, which differ in their impact resistance at low temperatures. This steel is widely used in heavy machinery, construction, bridges, vehicle frames, and high-stress equipment.Characteristics of Q550 Steel

Q550 steel offers high strength, toughness, good weldability, and excellent wear resistance, making it suitable for heavy machinery, construction, vehicle frames, bridges, and high-stress applications. Q550’s balance of durability and weldability ensures reliable performance across various demanding environments. For projects in extremely low temperatures, alternative grades such as Q690, Q960, or S690QL can be used to meet specific performance needs.Chemical Compositions

| Element | Content (%) |

|---|---|

| Iron, Fe | Balance |

| Carbon, C | 0.10 – 0.20 |

| Manganese, Mn | 1.00 – 1.60 |

| Silicon, Si | ≤ 0.50 |

| Phosphorus, P | ≤ 0.025 |

| Sulfur, S | ≤ 0.015 |

| Chromium, Cr | ≤ 0.30 |

| Nickel, Ni | ≤ 0.70 |

| Molybdenum, Mo | ≤ 0.10 |

| Vanadium, V | ≤ 0.12 |

| Copper, Cu | ≤ 0.40 |

Physical Properties

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Density | 7.85 g/cm³ | 0.283 lb/in³ |

| Melting Point | 1,425 – 1,460 °C | 2,597 – 2,660 °F |

| Boiling Point | ~3,000 °C | ~5,432 °F |

| Thermal Conductivity | 36 – 40 W/(m·K) | 25 – 28 BTU/(hr·ft·°F) |

| Electrical Conductivity | 6.99 MS/m | 6.99 MS/m |

| Specific Heat Capacity | 486 J/(kg·K) | 0.116 BTU/(lb·°F) |

| Thermal Expansion Coefficient | 11 – 13 × 10⁻⁶ /K | 11 – 13 × 10⁻⁶ /°F |

| Electrical Resistivity | 14.3 × 10⁻⁸ Ω·m | 14.3 × 10⁻⁸ Ω·m |

Mechanical Properties

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 550 – 620 MPa | 79,770 – 89,923 psi |

| Yield Strength | ≥ 550 MPa | ≥ 79,770 psi |

| Brinell Hardness | 170 – 235 HB | 170 – 235 HB |

| Rockwell Hardness | 83 – 95 HRB | 83 – 95 HRB |

| Vickers Hardness | 170 – 240 HV | 170 – 240 HV |

| Elongation | 16 – 20 % | 16 – 20 % |

| Elastic Modulus | 200 GPa | 29,000 ksi |

Data After QT(Quenching and Tempering) Processing

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 700 – 850 MPa | 101,500 – 123,000 psi |

| Yield Strength | ≥ 620 MPa | ≥ 89,923 psi |

| Brinell Hardness | 250 – 300 HB | 250 – 300 HB |

| Rockwell Hardness | 95 – 100 HRB / 35 – 40 HRC | 95 – 100 HRB / 35 – 40 HRC |

| Vickers Hardness | 270 – 330 HV | 270 – 330 HV |

| Elongation | 10 – 14% | 10 – 14% |

| Elastic Modulus | 200 GPa | 29,000 ksi |

Industries & Applications

| Industries | Products |

|---|---|

| Construction | Bridges, Beams, Columns, Trusses, Towers |

| Mining | Dump Trucks, Conveyor Systems, Crushers, Buckets, Drilling Equipment |

| Heavy Machinery | Excavators, Cranes, Bulldozers, Loaders, Drilling Rigs |

| Shipbuilding | Hulls, Decks, Containers, Support Frames, Ramps |

| Aerospace | Landing Gears, Structural Panels, Cargo Hold Frames, Ladders, Supports |

| Railways | Rail Tracks, Train Bogies, Couplers, Brake Components, Switchgear Frames |

| Automotive | Truck Frames, Chassis, Axles, Trailers, Reinforcement Bars |

| Energy | Wind Turbine Towers, Transmission Poles, Oil Rig Structures, Solar Frames, Offshore Platforms |

Machining

Q550 Steel Heat Treatment Steps

- Preheating:

- Heat to 150 – 200°C (302 – 392°F).

- Reduces thermal shock and minimizes cracking during further heating.

- Austenitizing:

- Heat to 880 – 920°C (1,616 – 1,688°F) and hold for 1 – 2 hours.

- Converts the steel’s structure to austenite, enhancing hardenability.

- Quenching:

- Rapidly cool in water or oil to room temperature.

- Increases hardness and strength by transforming austenite into martensite.

- Tempering:

- Reheat to 300 – 600°C (572 – 1,112°F) and hold for 1 – 2 hours.

- Relieves internal stresses, improves toughness, and adjusts hardness.

- Air Cooling:

- Allow steel to cool to room temperature in air.

- Stabilizes mechanical properties and ensures uniform hardness distribution.

Q550 Steel Surface Treatments

- Shot Blasting: Removes rust, scale, and surface contaminants, improving adhesion for coatings.

- Galvanizing: Coats the steel with a layer of zinc to prevent corrosion and enhance durability.

- Powder Coating: Provides a smooth, durable, and decorative finish with excellent corrosion resistance.

- Painting: Offers corrosion protection and aesthetic enhancement with customizable colors.

- Anodizing: Improves surface hardness and corrosion resistance, often used for specialized finishes.

- Plating (Nickel, Chromium): Enhances wear resistance, corrosion protection, and surface appearance.

- Laser Engraving or Etching: Creates permanent markings or designs for identification and branding.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...