S460ML STEEL – WIND AND SOLAR STEEL

S460ML STEEL – WIND AND SOLAR STEEL

S460ML is a high-strength structural steel grade commonly used in welded constructions. The designation “S460ML” indicates that it is a structural steel (“S”) with a minimum yield strength of 460 MPa (“460”), thermomechanically rolled (“M”), and suitable for low-temperature applications (“L”). Known for its excellent weldability, toughness, and high strength, S460ML is ideal for demanding engineering and construction projects such as bridges, buildings, and heavy machinery.

Description

What is S460ML?

S460ML is a high-strength structural steel primarily used in welded constructions. It is composed of approximately 0.18% carbon, 1.65% manganese, and 0.025% phosphorus, with the balance being iron. Typically supplied as solid plates, this steel offers excellent weldability, good toughness at low temperatures, and high strength. S460ML is mainly used in the construction of bridges, buildings, and other structures requiring high strength and toughness. It is produced through a thermomechanical rolling process and classified as a fine-grain structural steel.Characteristics of S460ML Steel

S460ML steel boasts high tensile strength (540-720 MPa), excellent stretch-flangeability (19% elongation), and good corrosion resistance due to its copper and chromium content. It maintains structural integrity at temperatures as low as -50°C, ensuring durability in harsh climates. With a fatigue strength of 290 MPa and low carbon content, it is suitable for various welding processes and reliable in both onshore and offshore structures. S460ML offers a yield strength of 460 MPa for thicknesses up to 16 mm and good impact strength (up to 58 J in V-Notched Charpy tests). Its balanced composition ensures excellent dimensional stability, high toughness, and resistance to crack propagation. The steel’s superior fatigue resistance, good machinability, and high resistance to brittle fracture make it ideal for cyclic loading applications and structural safety.Chemical Compositions

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.18 |

| Manganese (Mn) | ≤ 1.65 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.015 |

| Silicon (Si) | ≤ 0.50 |

| Nitrogen (N) | ≤ 0.012 |

| Copper (Cu) | ≤ 0.55 |

| Nickel (Ni) | ≤ 0.80 |

| Chromium (Cr) | ≤ 0.30 |

| Molybdenum (Mo) | ≤ 0.10 |

| Vanadium (V) | ≤ 0.12 |

| Titanium (Ti) | ≤ 0.05 |

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 7.85 g/cm³ | 0.284 lb/in³ |

| Melting Point | 1425°C – 1460°C | 2597°F – 2660°F |

| Thermal Conductivity | 34 W/m·K | 19.65 BTU·in/hr·ft²·°F |

| Specific Heat Capacity | 480 J/kg·K | 0.115 BTU/lb·°F |

| Electrical Resistivity | 0.20 x 10⁻⁶ Ω·m | 0.20 x 10⁻⁶ Ω·m |

Mechanical Properties

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 550 – 720 MPa | 79.8 – 104.4 ksi |

| Yield Strength | ≥ 460 MPa | ≥ 66.7 ksi |

| Brinell Hardness (HB) | 170 – 210 HB | 170 – 210 HB |

| Rockwell Hardness (HRC) | 17 – 22 HRC | 17 – 22 HRC |

| Vickers Hardness (HV) | 180 – 220 HV | 180 – 220 HV |

| Elongation | ≥ 17% | ≥ 17% |

| Elastic Modulus | 210 GPa | 30.5 Msi |

Industries & Applications

| Industry | Applications |

|---|---|

| Wind Energy Industry | Wind turbine towers, Nacelle frames, Rotor hubs, Foundation structures |

| Offshore Oil and Gas | Offshore platforms, Jack-up rigs, Subsea manifolds, Drilling derricks |

| Construction and Infrastructure | High-rise building columns, Bridge girders, Heavy-duty cranes, Stadium roof trusses |

| Shipbuilding | Ship hulls, Deck structures, Bulkheads, Offshore support vessels |

| Heavy Machinery | Excavator booms, Crane jibs, Mining equipment frames, Forestry machine chassis |

| Transportation | Railway bridges, Heavy-haul truck frames, Container handling equipment, Large cargo trailers |

| Power Generation | Hydroelectric dam structures, Nuclear power plant containment vessels, Thermal power plant boilers, Geothermal wellhead equipment |

| Aerospace | Launch pad structures, Satellite ground stations, Aircraft hangar frames, Rocket assembly facilities |

| Industrial Manufacturing | Heavy-duty conveyor systems, Large industrial presses, Furnace structures, Steel mill equipment frames |

Machining

S460ML Heat Treating Instructions: S460ML steel is supplied in a thermomechanically rolled condition, which provides its high strength and toughness. Additional heat treatment, such as quenching and tempering, is not necessary. However, if specific properties are required, the steel can be normalized or stress-relieved.

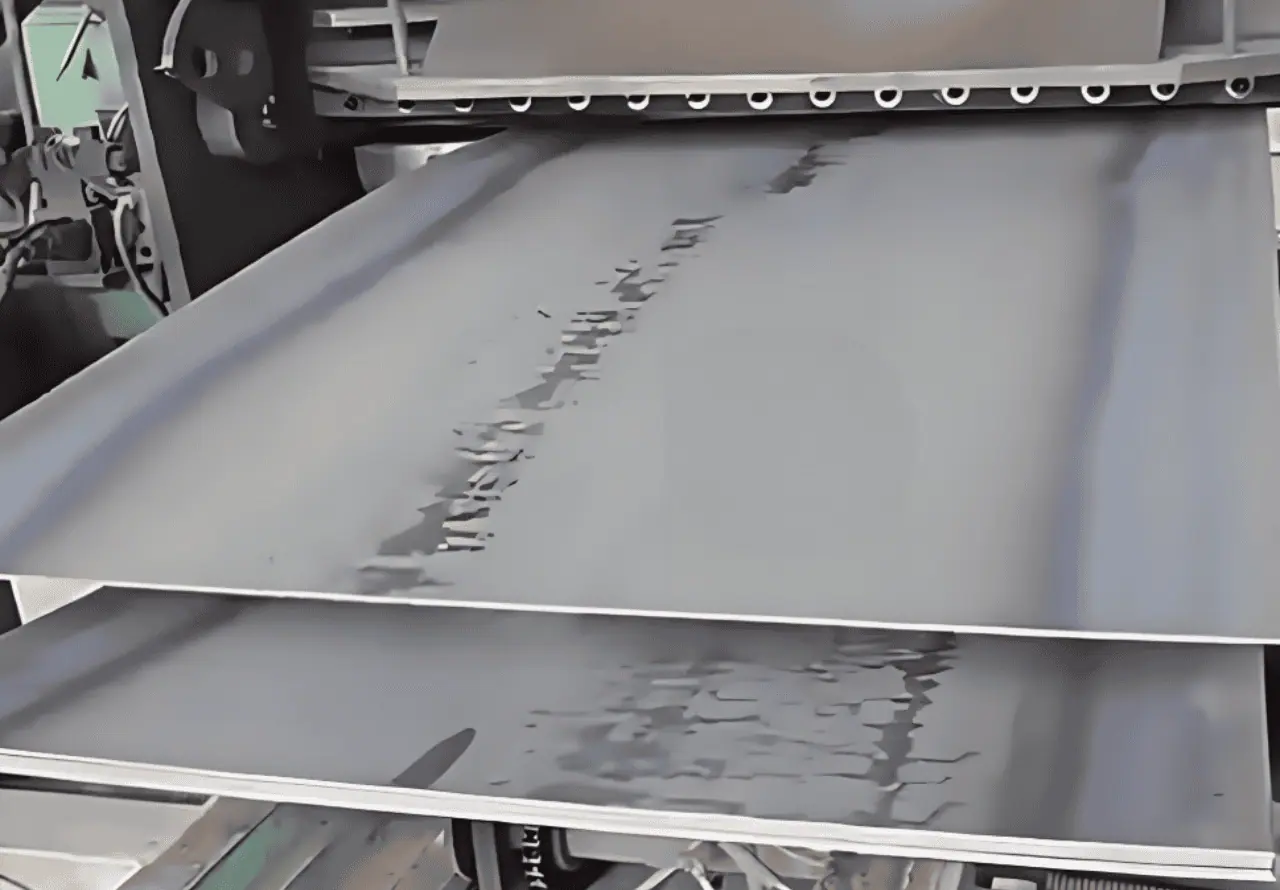

S460ML Surface Finish: The surface of S460ML steel can be treated through methods like shot blasting, painting, or galvanizing to enhance corrosion resistance and durability, especially in harsh environments.

Custom grades can be produced upon request to meet specific requirements.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...