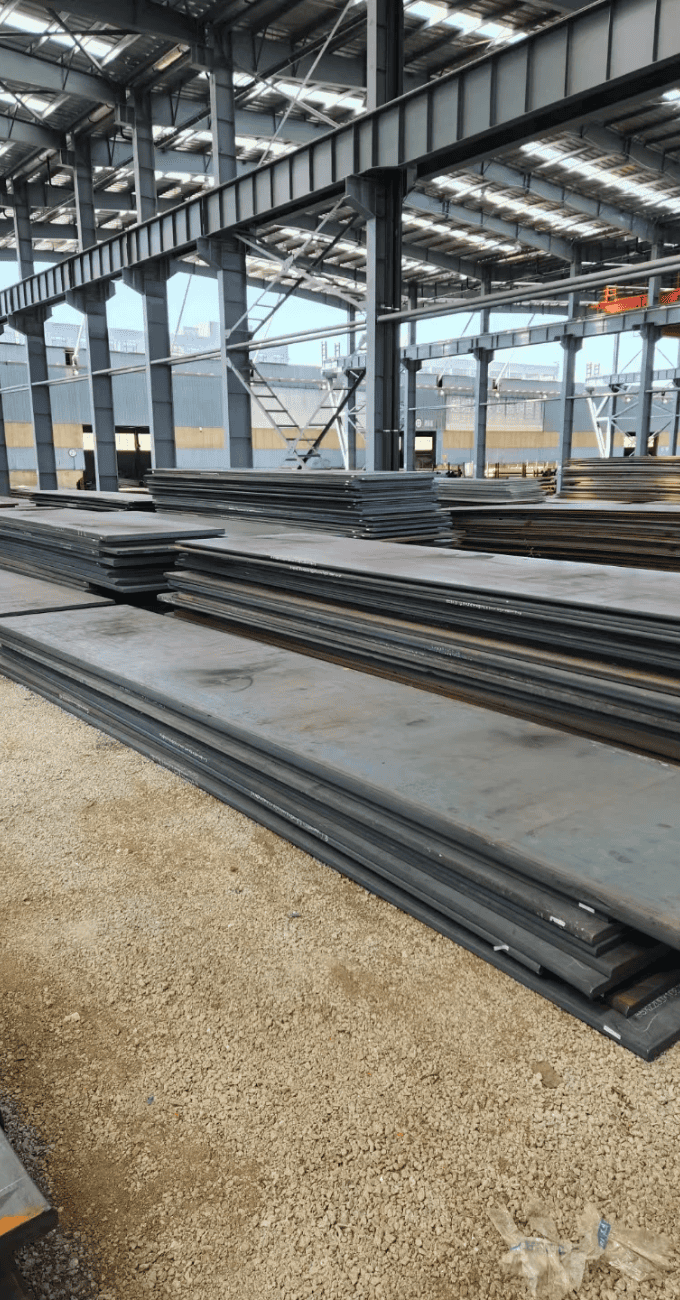

Introduction to Shipbuilding Steel

Shipbuilding steel is essential for constructing durable and reliable ships. This specialized steel plate is used in the shipbuilding industry to build the ship hull and other critical components.

Known for its excellent tensile strength and toughness, shipbuilding steel, such as EH36, ensures that ships can withstand harsh marine environments. It offers superior corrosion resistance and durability, making it a preferred choice for fabricating vessels. Different types of steel, including stainless steel and various alloys, are used in shipbuilding to achieve the necessary weld quality and yield strength required for safe and efficient maritime operations.

Benefits of Shipbuilding Steel

- Strong: High tensile strength ensures the ship hull remains intact.

- Resistant to Corrosion: Protects against rust, increasing the ship’s lifespan.

- Durable: Tough and long-lasting, ideal for harsh marine conditions.

- Versatile: Different grades like AH36, DH36, and EH36 for various needs.

- Easy to Weld: Ensures strong, secure joints in ship construction.

- Heat Treated: Enhanced durability and strength.

- Customizable: Available in various thicknesses and sizes.

- Cost-Effective: Low maintenance and long-lasting, saving money over time.

Primary Types of Shipbuilding Steel Used in Shipbuilding

Carbon steel and HSLA steel are the main types specifically classified as shipbuilding steel. Other types, like nickel steel, stainless steel, duplex stainless steel, maraging steel, weathering steel, and tool steel, are also used in shipbuilding but are not exclusively used for it.

- Carbon Steel (Mild Steel)

- Grades: A, B, D, and E

- Applications: Hulls, decks, and superstructures

- Properties: Good weldability, moderate strength, cost-effective

- High-Strength Low-Alloy (HSLA) Steel

Industries & Applications

Some common industries and applications include:

Shipbuilding

Offshore Structures

Marine Engineering

Container Ships

Repair and Maintenance

Naval Vessels

Fishing Boats

Cruise Ships

Dimensions & Properties

| Property | AH36 | DH36 | EH36 | FH40 |

|---|---|---|---|---|

| Yield Strength | 355 MPa (51.5 ksi) | 355 MPa (51.5 ksi) | 355 MPa (51.5 ksi) | 390 MPa (56.5 ksi) |

| Tensile Strength | 490-620 MPa (71-90 ksi) | 490-620 MPa (71-90 ksi) | 490-620 MPa (71-90 ksi) | 510-650 MPa (74-94 ksi) |

| Material Standard | ASTM A131/A131M | ASTM A131/A131M | ASTM A131/A131M | ASTM A131/A131M |

| Vickers Hardness | 160 HV | 160 HV | 160 HV | 170 HV |

High Strength Steels When & Where You Need It

Here, you get more than just quality steel. With multiple facilities across the country capable of providing high-strength steels, we can also work with you to manage your inventory, ensuring you get product when and where you need it to keep your production running.

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.

What steel is used in shipbuilding?

Shipbuilding primarily uses high-strength low-alloy steels, including grades like AH36, DH36, and EH36.

Why don't steel ships rust?

Steel ships are protected from rust by coatings, such as paint, and cathodic protection systems that prevent corrosion.

What grade of steel is used in shipbuilding?

Common grades used in shipbuilding are AH36, DH36, and EH36.

What is the difference between EH36 and DH36 steel?

EH36 steel has higher strength and toughness compared to DH36 steel, making it suitable for more demanding applications.

What is the steel grade DH36 equivalent to?

DH36 steel is equivalent to ASTM A131 Grade DH36 and can be compared to other international standards like ABS Grade DH36.