EH500 | High-Strength Shipbuilding Steel

EH500 | High-Strength Shipbuilding Steel

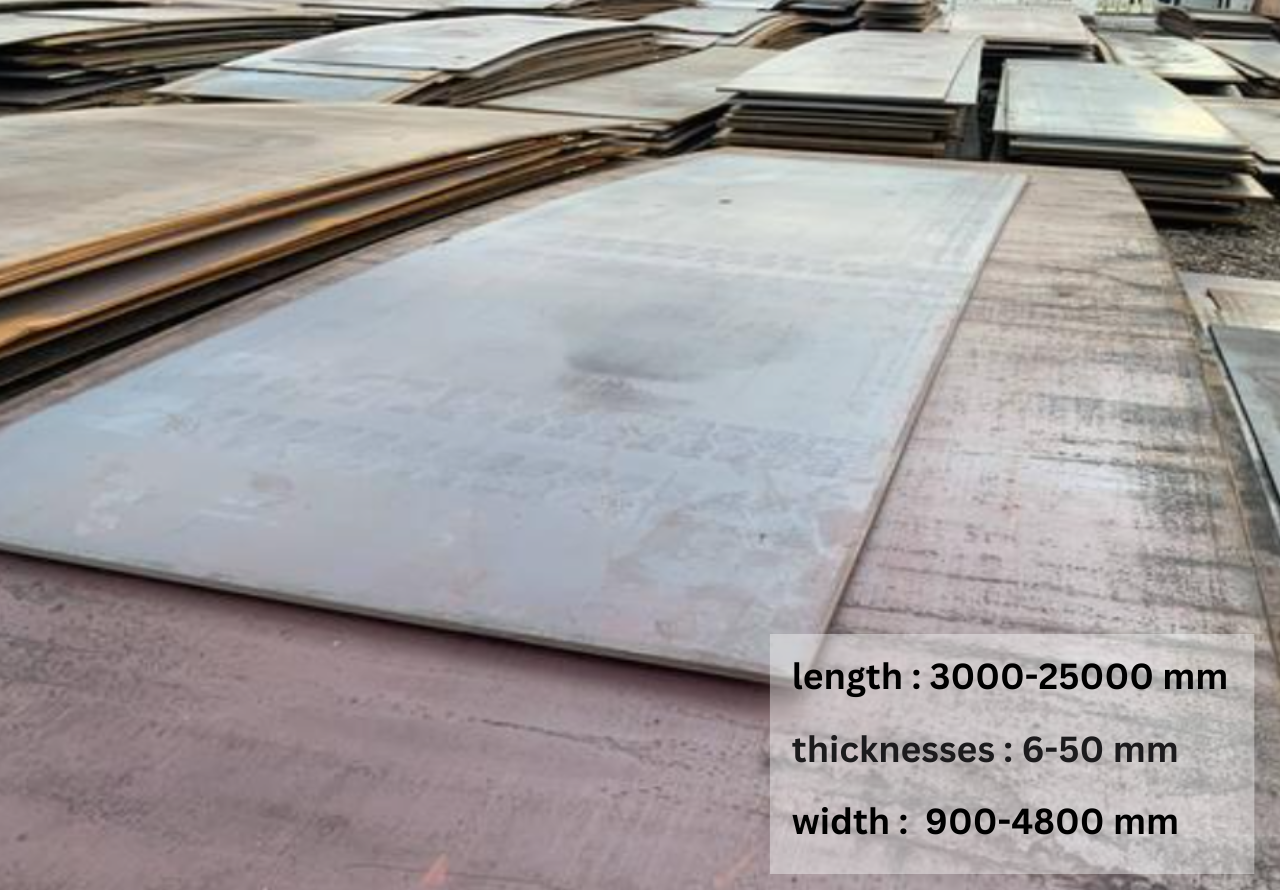

SteelPRO Group provides EH500 high-strength shipbuilding steel plates in stock.

Class Cert.: ABS/BV/CCS/DNV/KR/LR/NK/RINA/RS/PRS

Material: High-Strength Low-Alloy Steel

Thickness: 6-50 mm, or customized

Width: 900-4800 mm, or customized

Length: 3000-25000 mm, or customized

Condition of Delivery: A/HR/N/CR/Q+T/TMCP, or as request

Stock: In stock

Origin: Hebei/Henan/Jiangsu, China

Port: Qingdao

Description

What Is EH500?

EH500 steel is an ultra-high-strength structural steel designed for shipbuilding and offshore engineering. Its composition includes carbon, silicon, manganese, phosphorus, and sulfur, carefully balanced to ensure excellent strength, weldability, and toughness. “E” stands for toughness level at -40℃, “H” indicates its high strength, while “500” refers to its minimum yield strength of 500 MPa.

This steel offers exceptional impact resistance, remaining tough even in low temperatures down to -40°C. It is also highly weldable and corrosion-resistant, making it suitable for marine environments. With easy processability, EH500 is widely used in shipbuilding, offshore platforms, bridges, construction, and heavy machinery, ensuring stability and durability across industries.

Characteristics of EH500

- Strong and durable, capable of handling heavy loads.

- Resistant to corrosion and extreme environments.

- Offers a high strength-to-weight ratio, balancing performance and efficiency.

- Excellent weldability, facilitating easy fabrication.

- Widely used in construction, marine structures, and heavy machinery.

Chemical Compositions

| Element | Content (%) |

|---|---|

| Carbon, C | ≤ 0.18 |

| Manganese, Mn | 1.20-1.60 |

| Silicon, Si | ≤ 0.55 |

| Phosphorus, P | ≤ 0.020 |

| Sulfur, S | ≤ 0.010 |

| Chromium, Cr | ≤ 0.30 |

| Nickel, Ni | ≤ 0.30 |

| Molybdenum, Mo | ≤ 0.10 |

| Copper, Cu | ≤ 0.30 |

| Nitrogen, N | ≤ 0.012 |

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 7.85 g/cm³ | 0.283 lb/in³ |

| Melting Point | 1425–1530 °C | 2597–2786 °F |

| Thermal Conductivity | 43 W/m·K | 298 BTU·in/(hr·ft²·°F) |

| Electrical Conductivity | 10–15% IACS (relative to copper) | Same |

| Specific Heat Capacity | 460 J/kg·K | 0.110 BTU/lb·°F |

| Thermal Expansion Coefficient | 11.8 × 10⁻⁶ /°C | 6.56 × 10⁻⁶ /°F |

| Electrical Resistivity | 1.25 µΩ·m | 1.25 × 10⁻⁶ Ω·m |

Mechanical Properties

| Yield Strength (MPa min.) | Tensile Strength (MPa) | Elongation (% min.) | Test Temperature (°C) | Impact Energy (KV J min.) |

|---|---|---|---|---|

| 500 | 610-770 | 16 | -40 | 33 |

Note: the impact energy under less than 150mm thickness; longitudinal min impact energy.

Industries & Applications

| Industry | Application |

|---|---|

| Shipbuilding | Hull structures, Bulkheads, Deck plates, Stern frames |

| Offshore Engineering | Oil platforms, Subsea pipelines, Offshore cranes, Drilling rigs |

| Construction Machinery | Excavator arms, Bulldozer blades, Crane booms, Dump truck bodies |

| Mining Equipment | Dump truck trays, Conveyor belts, Crusher plates, Mining shovels |

| Heavy Transportation | Train car bodies, Heavy truck frames, Bridge supports, Tanker bodies |

| Wind Power Industry | Tower structures, Turbine blades, Gearbox components, Base plates |

| Military Applications | Armored vehicles, Naval vessels, Gun mounts, Missile launchers |

| Pressure Vessels | Storage tanks, Boilers, Pressure containers, Reactor vessels |

Machining

Heat Treatment

- Normalizing: Heat to 890-940°C, hold for sufficient time, then air cool to refine grain structure.

- Quenching: Heat to 880-920°C, hold, then quench in water or oil to increase hardness.

- Tempering: Reheat to 550-650°C, hold for desired time, and air cool to reduce brittleness and increase toughness.

Surface Finish

- Mill Finish: As-rolled surface without further treatment.

- Shot Blasting: Removes mill scale and improves surface texture.

- Painting/Coating: Applied for corrosion resistance, typically after blasting.

- Pickling: Acid treatment to remove scale and impurities.

- Polishing: Provides a smoother surface for specific applications.

*Customization is available upon request.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

QUESTION 1

QUESTION 2

QUESTION 3

QUESTION 4

QUESTION 4

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...