Contents

What Are Car Body Panels Made Of?

- John

Car body panels are essential components of any vehicle, playing a crucial role in both its aesthetics and functionality. In this article, we will explore the materials used in the production of car body panels and how these materials impact a car’s safety, durability, and efficiency.

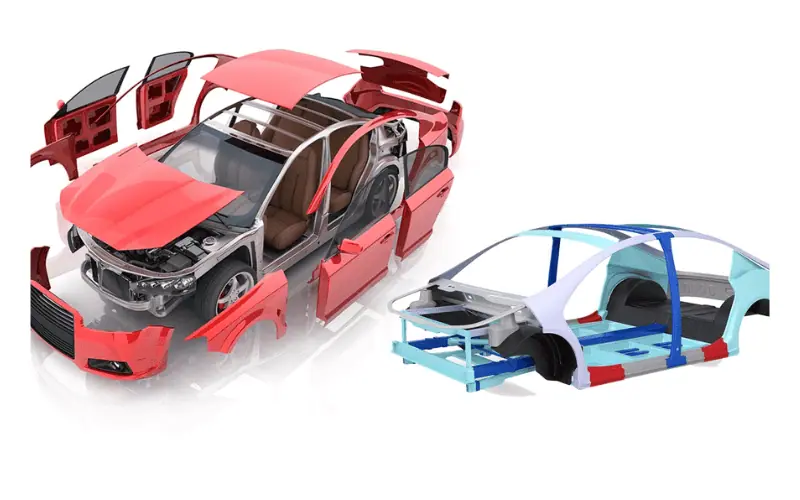

What Are Car Body Panels?

Car body panels are the exterior elements that shape a vehicle’s overall look and protect its internal components. These panels serve far more than a decorative function—they’re integral to both the design and performance of the vehicle. They cover the frame, contribute to aerodynamics, and offer crucial defense against external elements.

Body Panels Types

There are various types of body panels, each with a specific role:

- Fenders: Positioned over the wheels, fenders shield the vehicle from debris, dirt, and rocks that are kicked up by the tires. They also help with the car’s aerodynamics.

- Doors: Doors are, of course, essential for passenger entry and exit. However, they typically include safety elements such as side-impact reinforcement.

- Hoods: The hood protects the engine and makes it easy to reach for repairs.

- Bumpers: Located at the front and rear of the vehicle, bumpers absorb impact in low-speed collisions, minimizing damage to the car and enhancing safety.

- Roof Panels: These panels form the car’s roof and are typically designed with materials that reduce weight without compromising structural integrity.

Common Materials Used for Car Body Panels

Steel: The Traditional Choice

Steel has been the cornerstone of car body panels for decades. It is a cost-effective and dependable material recognized for its robustness and longevity. It offers outstanding collision resistance, making it a preferred option for crash protection. However, steel’s weight can reduce fuel efficiency and affect overall vehicle performance. Despite this, it remains widely used due to its cost-effectiveness and strength.

- Used in: Fenders, doors, hoods, roofs, and bumpers.

Aluminum: Lightweight and Strong

Aluminum is becoming increasingly favored in premium and high-performance automobiles. It’s much lighter than steel, improving fuel efficiency and vehicle performance. Moreover, aluminum’s ability to withstand corrosion makes it perfect for vehicles frequently subjected to severe weather conditions. Although aluminum is more expensive than steel, its benefits in terms of weight reduction and longevity often justify the higher cost.

- Used in: Hoods, doors, fenders, roofs, and trunks.

Plastic and Composite Materials

Polymers and synthetic composites, like polypropylene and fiberglass, are being utilized more frequently in vehicle body panels. These materials are light in weight, adaptable, and can be effortlessly shaped into intricate forms, allowing for versatile designs. They are also economical and highly resistant to rust and deterioration. However, while plastics and composites are durable and lightweight, they don’t always offer the same strength as metals, limiting their use in high-impact areas.

- Used in: Bumpers, fenders, interior panels, and trim.

Carbon Fiber: The Premium Material

Carbon fiber is the material of choice for high-end sports cars and performance vehicles. Known for its impressive strength-to-weight ratio, carbon fiber is incredibly lightweight yet extremely strong. It also resists corrosion, offering superior performance. However, carbon fiber’s high cost makes it impractical for mass-market vehicles, limiting its use to premium models.

- Used in: Hoods, roofs, fenders, doors, and high-performance components.

Magnesium: The Emerging Option

Magnesium, one of the lightest structural metals, is gaining attention in the automotive industry. Its light weight makes it an attractive choice for reducing vehicle mass and improving fuel efficiency. However, magnesium’s high cost and manufacturing challenges currently limit its widespread use. Ongoing research is gradually making it a more viable option, especially for lightweight vehicles.

- Used in: Engine compartments, seat frames, and lightweight body panels.

Advantages and Disadvantages of Each Material

| Material | Advantages | Disadvantages |

| Steel | Strong and durable, cost-effective, good impact resistance | Heavy, affects fuel efficiency, prone to corrosion |

| Aluminum | Lightweight, improves fuel efficiency, corrosion-resistant | Expensive, harder to repair, lower impact resistance |

| Plastic & Composites | Very lightweight, flexible and moldable, corrosion-resistant | Low impact resistance, less durable, can degrade with UV exposure |

| Carbon Fiber | Lightweight and strong, corrosion-resistant, high performance | Very expensive, difficult to repair, limited availability |

| Magnesium | Extremely lightweight, stronger than aluminum in some areas | High production cost, reactive to heat, less commonly used |

How Are Car Body Panels Manufactured?

The production of car body panels involves precision engineering, advanced materials, and efficient techniques to balance strength, weight, and cost. The process consists of several key steps, each ensuring the panels meet structural and aesthetic requirements.

1. Material Selection and Preparation

Manufacturing begins with selecting the right material based on the panel’s function. Steel, aluminum, plastic composites, and carbon fiber are prepared in sheets, rolls, or molded forms before shaping.

2. Stamping and Molding

Metal panels undergo stamping, where hydraulic presses shape steel or aluminum sheets into precise forms using heavy-duty dies. This ensures consistency and durability.

Plastic and composite panels, however, are made through molding techniques like injection molding, compression molding, or resin transfer molding (RTM). These processes allow for complex designs, often used for bumpers and lightweight exterior parts.

3. Welding and Assembly

Once shaped, metal panels are joined through spot welding or laser welding, enhancing structural integrity while minimizing excess weight. Plastic panels, instead of being welded, are assembled using adhesive bonding or mechanical fasteners, ensuring flexibility and durability.

4. Surface Treatment and Coating

To enhance resistance to corrosion and wear, panels undergo electrophoretic deposition (E-coating) and anti-chip treatments. Plastic and composite panels receive UV-resistant coatings to prevent sun damage and degradation.

5. Painting and Finishing

Panels then go through a multi-layer painting process, which includes primer application, a base coat, and a clear coat. Each layer is baked at high temperatures to ensure long-lasting color and durability.

6. Quality Inspection and Testing

Before installation, panels are subjected to rigorous testing for impact resistance, corrosion protection, and dimensional accuracy. These tests ensure the panels fit precisely and can withstand real-world conditions.

Smart Choice for Car Body Panels

At SteelPro Group, we supply DP600 sereies and DP800 series steel. Our products are engineered to meet the highest industry standards for vehicle body panels. Whether you’re designing for safety, efficiency, or performance, our materials ensure reliability in every component.