Contents

308 Stainless Steel: Definition, Composition, Properties, Processing, Pros & Cons, Applications and More

- John

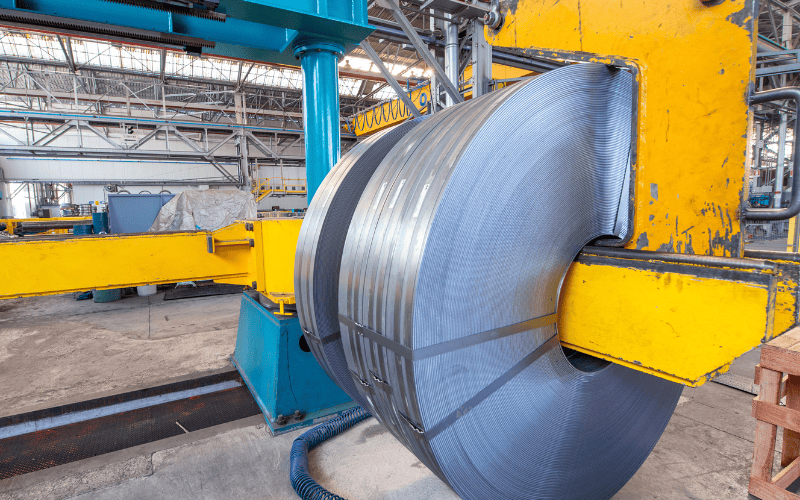

SteelPRO Group offers ASTM-standard hot/cold rolled 308 stainless steel in plates, sheets, coils, strips, bars, rods, pipes, tubes, wires, etc. We can also produce according to other international standards such as GB/T, EN, DIN, and JIS upon request. You can choose from a range of surface finishes, including No.1, 2D, 2B, BA, No.3, No.4, HL, 8K, etc. Can be delivered in hot-rolled (+HR), cold-rolled (+CR), annealed (+A), solution annealed (+SA), and other states. Most can be customized and we are very capable of doing customization for you.

Click here to browse our range of stainless steel products.

What Is 308 Stainless Steel?

308, also called S30800 (UNS), is a type of austenitic stainless steel in the 300 series, primarily composed of 20% chromium and 10% nickel. It conforms to standards such as ASTM A240 (for plate, sheet, and strip) and AWS A5.9 (for welding filler materials). Equivalent grades include X6CrNi19-11 (EN). Grade 308 SS is known for its excellent weldability and is commonly used as filler material, such as welding rod or wire, especially for welding 304 or similar types of stainless steel.

Why Was 308 Stainless Steel Developed?

308 stainless steel was specifically developed to enhance weldability and serve as an effective filler metal in welding applications. It is particularly suited for joining 304 stainless steel and other austenitic grades. The goal was to produce a type of stainless steel that maintains excellent corrosion resistance and mechanical properties while ensuring that welds are strong and durable. This development likely occurred in the 1950s or 1960s, a time when industries increasingly needed reliable and durable stainless steel materials for fabrication and construction.

Chemical Composition of 308 Stainless Steel

308 stainless steel is composed mainly of iron, chromium, and nickel. Iron is the base element constituting the balance of the alloy. Chromium is the highest alloying element, ranging from 19% to 21%. Nickel comes next, making up 9-11%. Additionally, smaller amounts of manganese, silicon, and carbon are present, along with trace amounts of phosphorus and sulfur.

| Chromium, Cr | Nickel, Ni | Carbon, C | Manganese, Mn | Silicon, Si | Phosphorus, P | Sulfur, S | Iron, Fe |

| 20% | 11.0% | ≤0.08% | ≤2.00% | ≤1.0% | ≤0.045% | ≤0.030% | Balance |

Properties of 308 Stainless Steel

Here are three major reasons that make 308 stainless steel unique:

- Excellent resistance to corrosion, especially in chloride environments.

- High tensile strength and durability make it ideal for structural applications.

- Good weldability minimizes the risk of weld decay.

Physical Properties

Check the table below for the core physical properties of 308 stainless steel:

| Property | Value | Performance |

| Density | 7.9 g/cm³ (0.285 lb/in³) | Good strength-to-weight ratio contributes to material stability and durability. |

| Melting Point | 1400 – 1455 °C (2552 – 2651 °F) | High; suitable for high-temperature applications. |

| CTE, Linear (0-100℃) | 17.3 µm/m°C (9.61 µin/in°F) | Moderate; ensure dimensional stability under temperature fluctuations. |

| Specific Heat Capacity (0-100°C) | 500 J/kg·K (0.119 Btu/lb·°F) | Efficient; suitable for thermal applications. |

| Thermal Conductivity ( 100°C) | 15.2 W/m·K (8.79 Btu·ft/h·ft²·°F) | Moderate; balance between strength and thermal performance. |

| Electrical Conductivity | 1.45 x 10⁶ S/m (2.51 % IACS) | Low conductivity; suitable for insulation |

| Magnetic Properties | Non-magnetic in annealed condition; slightly magnetic in cold-worked condition | Ideal for non-magnetic applications |

*CTE, Linear refers to the Coefficient of Thermal Expansion, Linear.

Mechanical Properties

Check the table below for the core mechanical properties of 308 stainless steel:

| Property | Value | Performance |

| Tensile Strength | 585 MPa (84.8 ksi) | Moderate; higher than mild steel; lower than high-strength steel |

| Yield Strength | 205 MPa (29.7 ksi) | Moderate; higher than aluminum alloys; lower than some other stainless steel |

| Brinell Hardness | 150 HB | Moderate; typical for austenitic stainless steel; softer than martensitic stainless steel |

| Rockwell Hardness | 80 HRB | |

| Vickers Hardness | 157 HV | |

| Elongation at Break | 55% | High; indicates good ductility, similar to other austenitic stainless steels |

| Young’s Modulus | 195 GPa (28.3 msi) | Typical; consistent with most stainless steel; stiffer than aluminum alloys |

Chemical Properties

Check the table below for the core chemical properties of 308 stainless steel:

| Chemical Property | Description | Performance |

| Corrosion Resistance | Resistance to oxidation or chemical reactions | High; better than mild steel, slightly less than 316 stainless steel in chloride environments |

| pH Sensitivity | Reaction to varying pH levels | Moderate; stable in neutral to mildly acidic/alkaline conditions, less so in extreme pH |

| Reactivity | Tendency to undergo chemical reactions | Low; generally inert, but reacts with strong acid |

| Oxidation Resistance | Resistance to surface oxidation at high temperatures | High; effective up to 800°C, less so than high-temp alloys |

| Passivation | Formation of a protective oxide layer | Excellent; forms a stable, self-healing passive film |

| Combustibility | Ability to catch fire | Non-combustible |

| Flammability | Ease of ignition | Non-flammable |

Processing Characteristics of 308 Stainless Steel

Let’s take a look at the processing characteristics of 308 stainless steel, mainly from the four aspects of forming, welding, machining, and heat treatment. Weldability, no doubt, is the most outstanding part of 308 stainless steel.

Formability

308 stainless steel is generally considered easy to form due to its good ductility, which allows it to be shaped without cracking. Its composition supports various forming processes, such as bending, drawing, and rolling. However, it may require more force compared to carbon steel due to its higher strength. Proper tools and techniques are essential for achieving the best results when forming 308 stainless steel.

Weldability

308 stainless steel is highly weldable due to its balanced composition, particularly the optimal amount of chromium and nickel. These elements reduce the risk of weld defects like cracking and distortion. During welding, 308 stainless steel forms a stable austenitic structure, minimizing issues such as hot cracking, which is more common in other stainless steels like 304 or 316.

While 304 and 316 stainless steels are also austenitic with both chromium and nickel content and generally resist hot cracking, they can be more prone to this issue under certain conditions. The reason lies in their composition. For instance, 316 contains molybdenum, which can affect solidification and slightly increase the risk of hot cracking in some welding scenarios. Similarly, 304 may experience hot cracking if impurity levels of sulfur and phosphorus are not well controlled.

Compared to carbon steel, 308 stainless steel has lower thermal conductivity and higher coefficient of expansion, which can lead to less heat input and lower risk of warping during welding. Additionally, its corrosion resistance remains high even after welding, making it preferable for applications where both strength and corrosion resistance are critical.

Can You Weld 316 With 308?

Yes, you can weld 316 stainless steel using 308 filler material, but it’s not ideal. The 308 filler is designed for welding 304 stainless steel and does not contain molybdenum, which is present in 316 stainless steel and provides additional corrosion resistance. Consequently, a weld using 308 filler may be less resistant to corrosion, particularly in harsh environments. For optimal performance and corrosion resistance, it’s better to use 316 or 316L filler material when welding 316 stainless steel.

Can You Use 308 on Mild Steel?

No, you should not use 308 filler material on mild steel. The 308 filler is formulated for welding stainless steel and is not suitable for mild steel. Using 308 on mild steel can result in poor weld quality, including issues such as cracking and weak welds due to the differences in material composition. For mild steel, it is best to use a filler material specifically designed for it, such as ER70S-6.

Machinability

308 stainless steel is generally considered challenging to machine due to its toughness and tendency to work harden. When machining 308 stainless steel, it’s important to use sharp tools and maintain consistent cutting speeds to prevent excessive heat buildup. Proper lubrication or cutting fluids can also improve the machining process by reducing heat and friction. Additionally, using slow feed rates helps minimize the risk of work hardening, which can make the machining process more difficult and reduce tool life.

Hardenability

Like 304 and 316, 308 cannot be hardened through heat treatment. This is because it is an austenitic stainless steel, which does not respond to heat treatment for hardening due to its crystal structure. Instead, 308 stainless steel maintains or increases its strength through cold working processes such as rolling or bending.

What Are the Advantages and Disadvantages of 308 Stainless Steel?

Here are the advantages and benefits of 308 stainless steel:

- Strong corrosion resistance, especially in acidic environments.

- Good heat resistance, making it suitable for high-temperature applications.

- Durable and long-lasting, providing reliability over time.

- Good weldability, allowing for easier fabrication and construction.

- Versatile, suitable for various industrial and commercial applications.

The disadvantages and limitations of 308 stainless steel are listed below:

- Susceptible to stress corrosion cracking in certain environments.

- Not suitable for environments with high chloride levels, which can lead to pitting.

- Higher cost compared to other types of stainless steel.

- Requires specific welding techniques to maintain its properties, increasing fabrication complexity.

- Lower formability, making it more difficult to shape or mold.

Common Applications of 308 Stainless Steel

For your convenience, check the table below for a quick understanding:

| Industry | Application | Why 308 Suits |

| Aerospace | Aircraft frames, jet engines, landing gear, exhaust systems | High strength at elevated temperatures, excellent corrosion resistance. |

| Automotive | Exhaust manifolds, catalytic converters, mufflers, fuel tanks | Good oxidation resistance, ideal for high-temperature automotive components. |

| Construction | Structural components, facades, roofing, support beams | High tensile strength, durability, and structural integrity. |

| Chemical Processing | Heat exchangers, tanks, piping, pressure vessels | Resistant to chemical corrosion, withstand high pressures. |

What Is 308 Best for?

308 stainless steel is best for welding applications, especially when welding stainless steel of similar composition, like 304 stainless steel. It’s often used in the production of welding rods and wire.

Equivalent Grades of 308 Stainless Steel in Different Countries and Regions

Here are some common equivalent grades of 308 SS in different countries and regions:

| Country | Standard/Specification | Equivalent Grade |

| China | GB/T 3280 | 0Cr21Ni10 |

| USA | ASTM A240 | 308 |

| Germany | DIN EN 10088-2 | 1.4316 (X6CrNi19-11) |

| Russia | GOST 5632 | 12X19H9 |

| Europe | EN 10088-2 | X6CrNi19-11 (1.4316) |

| Japan | JIS G4303 | SUS 308 |

| UK | BS 1449 | 308S25 |

Comparison Between 308 vs 304 vs 316 Stainless Steel

Check the table below for a quick comparison between the three:

| Property | 308 | 304 | 316 |

| Type | Austenitic | Austenitic | Austenitic |

| Crystal Structure | FCC (Face-Centered Cubic) | FCC (Face-Centered Cubic) | FCC (Face-Centered Cubic) |

| Main Composition | Cr: 20%, Ni: 11% | Cr: 18-20%, Ni: 8-10.5% | Cr: ≤18%, Mo: ≤3%, Ni: ≤14% |

| Corrosion Resistance | Moderate | Good | Excellent |

| Strength | Good | Good | Higher |

| Hardness | Moderate | Moderate | Moderate |

| Weldability | Good | Excellent | Good |

| Magnetic Properties | Non-magnetic | Non-magnetic | Non-magnetic |

| Cost | Higher than 304 | Baseline | Higher than 304 |

| Applications | Welding, fabrication, heat exchangers | General-purpose applications | Marine, chemical processing, medical devices |

What You Might Also Concern

Now that you have a deeper understanding of 308 stainless steel, there are still some common issues that deserve your attention:

Is Stainless Steel 308 Magnetic?

Stainless Steel 308 is generally not magnetic because it has an austenitic crystal structure, which is stabilized by the addition of nickel. This structure does not have the magnetic properties found in other types of stainless steel, like ferritic or martensitic grades. However, it can become slightly magnetic after cold working.

Is 304 or 308 Stainless Steel Better?

304 stainless steel is generally better for most applications due to its versatility and lower cost. However, 308 is preferred for welding applications due to its higher chromium and nickel content, which provides better heat resistance and corrosion protection in welded joints.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons