Introduction to Stainless Steel

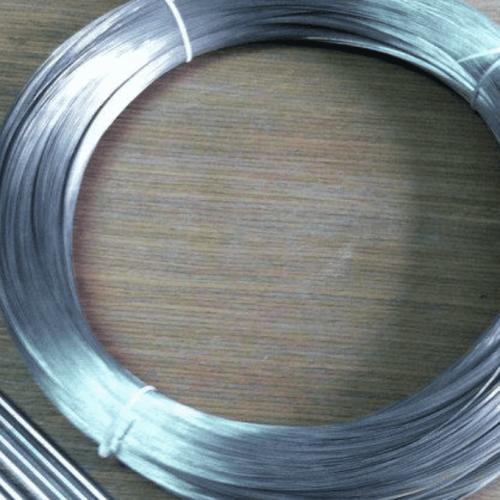

Stainless steel is a strong and durable alloy known for its excellent corrosion resistance. It is made by alloying iron with chromium, nickel, and other elements, which forms a chromium oxide layer that protects the metal. Stainless steel typically has a tensile strength ranging between 480-2,000 MPa (70-290 ksi) and a yield strength between 170-1,000 MPa (25-145 ksi), allowing it to withstand significant stress without deforming.

There are various types of stainless steel, including austenitic, martensitic, ferritic, and duplex, each offering different mechanical properties and levels of corrosion resistance. Its resilience and sleek appearance make stainless steel a popular choice for a wide range of applications, from kitchen appliances to medical equipment.

Benefits of Stainless Steel

- Corrosion Resistance: Long-lasting protection against rust and stains.

- High Durability: Strong and reliable, withstands wear and tear.

- Hygienic: Easy to clean, prevents bacterial growth.

- Heat Resistance: Maintains strength at high temperatures.

- Eco-friendly: Fully recyclable.

- Aesthetic Appeal: Sleek and modern finish.

Types & Grades of Stainless Steel

Carbon steel and HSLA steel are the main types specifically classified as shipbuilding steel. Other types, like nickel steel, stainless steel, duplex stainless steel, maraging steel, weathering steel, and tool steel, are also used in shipbuilding but are not exclusively used for it.

- Austenitic: 304, 316, 321, 347

- Applications: Kitchenware, chemical processing, architecture.

- Ferritic: 430, 409, 439, 444

- Applications: Automotive exhausts, appliances, industrial equipment.

- Martensitic: 410, 420, 440C, 431

- Applications: Cutlery, surgical instruments, industrial blades.

- Duplex: 2205, 2507

- Applications: Oil and gas industry, marine environments.

- Precipitation-Hardening: 17-4 PH, 15-5 PH

- Applications: Aerospace, chemical, petrochemical industries.

Industries & Applications

Some common industries and applications include:

Architecture & Construction

Automotive & Transportation

Medical & Healthcare

Food & Beverage Processing

Chemical & Petrochemical

Energy & Power Generation

Aerospace & Aviation

Marine & Shipbuilding

Dimensions & Properties

| Property | 304 | 316 | 430 | 201 | 410 | 2205 |

|---|---|---|---|---|---|---|

| Yield Strength | 215 MPa (31.2 ksi) | 205 MPa (29.7 ksi) | 275 MPa (39.9 ksi) | 275 MPa (39.9 ksi) | 275 MPa (39.9 ksi) | 450 MPa (65.3 ksi) |

| Tensile Strength | 505 MPa (73.2 ksi) | 515 MPa (74.7 ksi) | 450 MPa (65.3 ksi) | 515 MPa (74.7 ksi) | 480 MPa (69.6 ksi) | 620 MPa (89.9 ksi) |

| Material Standard | ASTM A240/A240M | ASTM A240/A240M | ASTM A240/A240M | ASTM A666/A666M | ASTM A240/A240M | ASTM A240/A240M, ASTM A790 |

| Vickers Hardness | 129 HV | 152 HV | 183 HV | 220 HV | 192 HV | 293 HV |

High Strength Steels When & Where You Need It

At Steel Pro Group, you get more than just quality steel. With multiple facilities across the country capable of providing high-strength steels, we can also work with you to manage your inventory, ensuring you get product when and where you need it to keep your production running.

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.

What is stainless steel made of?

What is the difference between stainless steel and regular steel?

Stainless steel contains chromium, which provides corrosion resistance, while regular steel does not.

Which type of stainless steel is the best?

Which grade of stainless steel is the best?

The best grade of stainless steel depends on the application, but for general use, 304 stainless steel is often considered the best due to its excellent corrosion resistance, durability, and affordability. For marine environments, 316 stainless steel is preferred due to its higher corrosion resistance.

Does stainless steel rust?

Stainless steel can rust under certain conditions, especially if the protective chromium oxide layer is damaged. However, it is much more resistant to rust compared to regular steel.