Contents

304 Stainless Steel: Definition, Composition, Properties, Processing, Applications, and More

- John

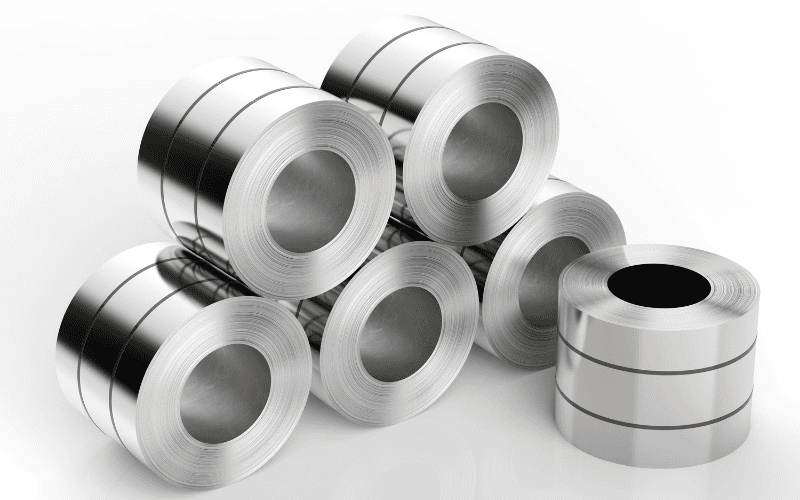

SteelPRO Group offers ASTM or requested standard hot/cold rolled 304 stainless steel sheets, plates, coils, strips, bars, rods, pipes, tubes, wires, etc., for your various project requirements. We can provide a range of finishes such as 2B, No.4, HL, BA, No.1, No.8, etc. Sizes can be customized. Alternative grades such as 316, 321, and 430 stainless steel are also available. We guarantee 100% free of quality issues. Contact our sales team for a free sample!

→Click here to browse our 304 stainless steel series products

What is 304 stainless steel?

304 stainless steel, also called A2 or 18/8, is a type of austenitic stainless steel with a face-centered cubic (FCC) crystal structure, primarily composed of 18% chromium and 8% nickel. It conforms to the ASTM A240 standard with equivalent grades like 1.4301 (EN) and SUS304 (JIS). 304 stainless steel is known for its better corrosion resistance than regular steel and is non-magnetic. Common applications include kitchen equipment, chemical containers, and architectural structures. It is typically processed through cold working and cannot be heat treated.

Who Developed 304 Stainless Steel?

304 stainless steel was developed by W.H. Hatfield in 1924 while he was working at Firth Brown Laboratories in Sheffield, England. Hatfield built on the earlier work of Harry Brearley, who had pioneered stainless steel. He created a steel alloy containing 18% chromium and 8% nickel, which is now known as 18/8 stainless steel. This alloy, later named 304 stainless steel, was initially marketed under the trade name “Staybrite 18/8.” It became one of the most widely used stainless steel due to its corrosion resistance and durability.

Chemical Composition of 304 Stainless Steel

Check the table below for the chemical composition of 304 stainless steel:

| Iron, Fe | Chromium, Cr | Nickel, Ni | Manganese, Mn | Silicon, Si | Carbon, C | Nitrogen, N | Phosphorus, P | Sulfur, S |

| Balance | 18-20% | 8-10.5% | ≤2.0% | ≤1.0% | ≤0.08% | ≤0.10% | ≤0.045% | ≤0.03% |

Properties of 304 Stainless Steel

Here are three major reasons that make 304 stainless steel unique:

- High resistance to corrosion, especially rust and staining.

- Durable, strong, and easily weldable into complex forms.

- Widely used across various industries due to its versatility.

Physical Properties

Check the table below for the core physical properties of 304 stainless steel:

| Property | Typical Value (Metric/Imperial) | Performance |

| Density | 8.00 g/cm³ (0.289 lb/in³) | High density provides good durability and strength. |

| Melting Point | 1400-1455°C (2550 – 2650 °F) | High melting point makes it suitable for high-temperature applications. |

| Thermal Conductivity (100°C) | 16.2 W/m·K (9.36 BTU/hr·ft·°F) | Moderate thermal conductivity is effective for heat dissipation. |

| CTE, Linear (20℃) | 17.3 µm/m-°C (9.61 μin/in·°F) | Low thermal expansion minimizes deformation with temperature changes. |

| Specific Heat Capacity (0-100°C) | 500 J/kg·K (0.12 BTU/lb·°F) | High; suitable for applications involving heat exchange or thermal stability. |

| Electrical Conductivity | 2.5 % IACS | Low electrical conductivity is beneficial for certain electronic applications. |

| Magnetic Properties | Generally non-magnetic | Non-magnetic nature is useful in environments where magnetism can interfere. |

*CTE, Linear refers to the Coefficient of Thermal Expansion, Linear.

Mechanical Properties

Check the table below for the core mechanical properties of 304 stainless steel:

| Mechanical Property | Value (Metric/Imperial) | Performance |

| Tensile Strength | 505 MPa (73.2 ksi) | Moderate; good tensile strength compared to mild steel |

| Yield Strength | 215 MPa (31.2 ksi) | Moderate; slightly lower than mild steel, typical for stainless steel |

| Brinell Hardness | 123 HB | Moderate; indicates average wear resistance and ductility suitable for forming |

| Rockwell Hardness | 70 HRB | |

| Vickers Hardness | 129 HV | |

| Elongation at Break | 70% | Very high; excellent ductility compared to mild steel |

| Young’s Modulus | 193 GPa (28 msi) | High; more rigid than aluminum alloys, slightly lower than carbon steel |

Chemical Properties

Check the table below for the core chemical properties of 304 stainless steel:

| Chemical Property | Description | Performance |

| Corrosion Resistance | Ability to resist deterioration from chemical reactions | Excellent; superior to many steels but less effective in chloride-rich environments compared to 316 stainless steel |

| pH Sensitivity | Response to different pH levels | Maintains stability across a wide pH range; versatile for various applications |

| Reactivity | Tendency to react chemically | Low; does not react easily with most substances |

| Oxidation Resistance | Resistance to forming oxides | High; forms a protective oxide layer due to high chromium content |

| Passivation | Formation of a protective layer | High; passivates well; enhances corrosion resistance |

| Combustibility | Ability to catch fire | Non-combustible |

| Flammability | Ability to sustain combustion | Non-flammable |

Heat & Corrosion Resistance of 304 Stainless Steel

Heat Resistance

304 stainless steel has good heat resistance, with intermittent service up to 870°C and continuous service up to 925°C. However, continuous use in the temperature range of 425°C – 860°C is not recommended due to the risk of carbide precipitation.

In this case, 304L is preferred, especially if welding is required, as it resists carbide precipitation due to lower carbon content. If high strength is required at 500°C – 800°, 304H is a better choice.

Corrosion Resistance

304 stainless steel has good corrosion resistance. It resists rusting and corrosion in many environments, including in damp air, fresh water, and mild chemicals.

However, 304 stainless steel can corrode in harsh conditions. It is susceptible to pitting and crevice corrosion in chloride-rich environments, such as seawater or salty air. It may also experience stress corrosion cracking when exposed to high temperatures above 60°C (140°F) in combination with chlorides.

Processing of 304 Stainless Steel

Forming

304 stainless steel is easy to form with its austenitic microstructure and can undergo significant deformation. Its low carbon content also helps prevent brittleness during forming.

Specifically, 304 stainless steel can be hot formed at temperatures between 900°C and 1180°C (1650°F and 2150°F). After extensive hot forming, it may require annealing to relieve stress and maintain its corrosion resistance. Cold working increases its strength and hardness without the need for heat treatment.

Welding

304 stainless steel is easy to weld due to its austenitic structure and works well with common welding methods such as TIG, MIG, and resistance welding.

The most used filler material for welding 304 stainless steel is 308L stainless steel. This filler matches the composition of 304 and offers good corrosion resistance. Post-weld annealing is generally not required unless the weld is exposed to severely harsh, corrosive environments or if there’s a concern about stress corrosion cracking.

Machining

304 stainless steel has moderate machinability. It is not as easy to machine as carbon steel, with machinability around 45-55% of that of free-machining carbon steel. However, it is still better than some other stainless steel, such as 316.

When machining 304, it’s important to consider its tendency to work-harden. This means that the material becomes harder as it’s being cut, which can make the process more difficult and lead to tool wear. Using sharp tools and appropriate cutting speeds can help manage this. Cooling is also crucial to prevent overheating, which can further increase hardness and cause surface issues. Proper lubrication can reduce friction and improve tool life.

Heat Treatment

304 stainless steel cannot be hardened by heat treatment. It achieves higher hardness through cold working. Heat treating involves annealing to relieve stress and restore corrosion resistance. The typical heat treatment process is:

- Solution Annealing: Heat to 1010–1120°C (1850–2050°F), followed by rapid cooling (usually water quenching). This dissolves carbides and retains the alloy’s austenitic structure.

- Stress Relief: If required, it can be done at lower temperatures (around 450-600°C) to minimize distortion and internal stresses.

Advantages and Disadvantages of 304 Stainless Steel

Here are the advantages and benefits of 304 stainless steel:

- Strong resistance to rust and corrosion, especially in everyday environments.

- Easy to shape and mold, making it suitable for a variety of designs.

- Can be welded easily for efficient fabrication and joining processes.

- Safe and clean, perfect for food and medical uses.

- Affordable and widely available, making it a popular choice.

Here are the disadvantages and limitations of 304 stainless steel:

- Susceptible to pitting and crevice corrosion in chloride environments.

- Doesn’t perform well under very high temperatures.

- Can crack under stress in certain environments, particularly in the presence of chlorides.

- Not strong enough for heavy-duty applications without extra processing.

- Harder to machine than carbon steel, potentially increasing manufacturing costs.

Common Applications of 304 Stainless Steel

Check the table below for a quick view of its common applications:

| Industry | Application | Why It Suits |

| Food & Beverage | Kitchen Sinks, Food Processing Equipment, Brewery Tanks, Dairy Equipment | Corrosion-resistant, easy to clean, non-reactive, maintains hygiene, withstands cleaning |

| Medical | Surgical Instruments, Hospital Equipment, Orthopedic Implants, Dental Tools | High corrosion resistance, sterilizability, biocompatible, durable, easy to maintain hygiene |

| Automotive | Exhaust Systems, Trim and Moldings, Fuel Tanks, Engine Parts | Heat-resistant, corrosion-resistant, attractive finish, maintains structural integrity |

| Construction | Architectural Panels, Handrails, Elevator Doors, Fasteners | Corrosion-resistant, maintains appearance, durable, low maintenance, resists environmental damage |

Equivalent Grades of 304 Stainless Steel in Different Countries and Regions

Here are some common equivalent grades of SS 304 in different countries and regions:

| Country | Standard/Specification | Equivalent Grade |

| China | GB/T 3280 | 0Cr18Ni9 |

| USA | ASTM A240 | 304 |

| Germany | DIN EN 10088-2 | 1.4301 (X5CrNi18-10) |

| Russia | GOST 5632 | 08Х18Н10 |

| Europe | EN 10088-2 | X5CrNi18-10 (1.4301) |

| Japan | JIS G4303 | SUS 304 |

| UK | BS 1449 | 304S15, 304S16, 304S31 |

Variants of 304 Stainless Steel

Below are some of the common variants of 304 stainless steel:

| Variant | What is it? | Why might it be chosen instead of 304? | Typical Application |

| 304L | Low carbon version of 304 | Better corrosion resistance after welding | Chemical processing, piping |

| 304H | High carbon version of 304 | Better high-temperature strength | Power plants, boilers |

| 304N | Nitrogen-enhanced 304 | Higher strength and toughness | Structural applications |

| 304LN | Nitrogen-enhanced, low carbon 304 | Improved weldability, strength, and corrosion resistance | Cryogenic vessels, heat exchangers |

*Note:

- 304L contains ≤0.03% carbon, while 304H contains 0.040 – 0.10 % carbon.

- Certain products may be offered as “dual certified” materials, like 304/304L, that meet both mechanical strength and corrosion resistance requirements.

- 304L is easier to weld without post-weld annealing due to lower carbon content, which enhances its fabrication suitability. 304H, with higher carbon content, might be more brittle in some forming processes.

- 304LN performs better in extremely low temperatures compared to standard 304 stainless steel.

Difference Between 304 vs 316 Stainless Steel

The major difference between 304 and 316 stainless steel lies in their composition, which leads to different corrosion resistance, applications, and cost. Check the table below for a quick comparison:

| Property | 304 | 316 |

| Chemical Composition | Cr: 18-20%, Ni: 8-10.5% | Cr: ≤ 18%, Ni: ≤ 14%, Mo: ≤ 3% |

| Corrosion Resistance | General resistance, suitable for normal environments | Higher resistance, especially in chloride and marine environments |

| Applications | Kitchen utensils, automotive trim, building materials, etc. | Chemical, marine, pharmaceutical equipment, etc. |

| Cost | Lower | Higher |

What You Might Also Concern

Now that you have a deeper understanding of 304 stainless steel, there are still some common issues that deserve your attention:

Does 304 stainless rust?

Yes, 304 stainless steel can rust under certain conditions, such as exposure to saltwater, chlorine, or acidic environments.

Does 304 stainless steel tarnish?

No, 304 stainless steel does not typically tarnish. It is resistant to tarnishing due to its chromium content, which forms a protective oxide layer on the surface. However, it may lose its luster if exposed to harsh chemicals or poor maintenance.

Does 304 stainless steel scratch easily?

Yes, 304 stainless steel can scratch relatively easily. It’s not hard enough because of its relatively low carbon content and lack of hardness-increasing elements like molybdenum or vanadium. The softer surface can be marked by abrasive materials, rough handling, or contact with harder objects.

Is 304 stainless steel food safe?

Yes, 304 stainless steel is food safe. It is commonly used in kitchen appliances, cookware, and food processing equipment because it is non-reactive, resists corrosion, and does not leach harmful substances into food.

Which is better, 304 or 316 stainless steel?

It depends on specific requirements. 316 stainless steel is better than 304 for harsher environments due to its added molybdenum, which provides greater corrosion resistance. However, 304 is more commonly used and is sufficient for many general-purpose applications where extreme corrosion resistance isn’t necessary.

SteelPRO Group Stainless Steel Stocking

SteelPRO Group covers most of the commonly used stainless steel grades in various shapes:

- Austenitic: 304, 316, 317, 321, 904, etc.

- Ferritic: 409, 430, etc.

- Martensitic: 420, 431, 439, etc.

- Duplex: 2205, 2507, etc.

- Precipitation Hardening: 17-4PH, 17-7PH, etc.

Click here to browse our range of stainless steel for your projects.

- Stainless Steel Grades

- 300 Series Stainless Steel

- 303 Stainless Steel

- 304 Stainless Steel

- 305 Stainless Steel

- 308 Stainless Steel

- 316 Stainless Steel

- 316N Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 416 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 410HT And 410L Stainless Steels

- 410S Stainless Steel

- 440 Stainless Steel

- 436 Stainless Steel

- 301 Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 444 Stainless Steel

- 405 Stainless Steel

- 302 Stainless Steel

- 309 Stainless Steel

- 314 Stainless Steel

- 321 Stainless Steel

- 347 Stainless Steel

- 408 Stainless Steel

- 422 Stainless Steel

- 431 Stainless Steel

- 434 Stainless Steel

- 414 Stainless Steel

- 430FR Stainless Steel

- 13-8 PH Stainless Steel

- 317 | 317L Stainless Steel

- 616 Stainless Steel

- 630 Stainless Steel

- 904L Stainless Steel

- A2 Stainless Steel

- 304 vs 304L Stainless Steel

- 304 VS 316 Stainless Steel

- 304 vs 409 Stainless Steel

- 304 vs 430 Stainless Steel

- 410 Stainless Steel vs 304

- 18/0 vs 18/10

- 18/0 Stainless Steel

- 18/8 Stainless Steel

- 18/10 Stainless Steel

Comparisons