Contenido

Acero inoxidable A2: propiedades, características y comparación

- John

El acero inoxidable A2 es muy valorado por su excepcional resistencia a la corrosión y durabilidad. Se ha convertido en una opción popular para herramientas y sujetadores diseñados para soportar condiciones difíciles y exigentes.

Este artículo ofrece una descripción general completa del acero inoxidable A2, que abarca su composición, propiedades y aplicaciones. También analiza los diferentes grados de acero inoxidable (A2-50, A2-70 y A2-80) y ofrece una comparación entre el acero inoxidable A2 y otros grados de acero inoxidable, como 304, A4 y A8.

¿Qué es el acero inoxidable A2?

El acero inoxidable A2 es un acero inoxidable austenítico. Contiene entre un 65 y un 70 % de hierro (Fe), entre un 18 y un 20 % de cromo (Cr) y entre un 8 y un 10,5 % de níquel (Ni), con pequeñas cantidades de carbono, manganeso y silicio. Tiene una superficie plateada ligeramente reflectante. Su resistencia a la corrosión es excelente y tiene un equilibrio entre durabilidad y trabajabilidad. Sus usos más comunes incluyen equipos de cocina, elementos arquitectónicos, componentes automotrices y contenedores de productos químicos.

- ¿Es el acero inoxidable A2 igual que el 304?

No son lo mismo, pero están estrechamente relacionados. 304 es una clasificación internacional de aleaciones. A2 es una designación europea comúnmente utilizada para los elementos de fijación de acero inoxidable y normalmente se refiere al acero inoxidable 304.

Equivalentes de acero inoxidable A2

| País/Región | Norma/Especificación | Grado equivalente |

| China | GB/T 1220, GB/T 20878 | 06Cr19Ni10 (o 304) |

| EE.UU. | ASTM A276, ASTM A240 | 304 |

| UE | EN 10088-2 | X5CrNi18-10 (1.4301) |

| Alemania | DIN EN 10088-2 | X5CrNi18-10 |

| Japón | JIS G4303 | SUS304 |

| Inglaterra | BS EN 10088-2 | 304S15 |

Subgrupos de acero inoxidable A2

El acero inoxidable A2, ampliamente reconocido por su excelente resistencia a la corrosión en entornos no marinos, se clasifica en tres subgrados: A2-50, A2-70 y A2-80. Estas clasificaciones se basan en su resistencia a la tracción y sus propiedades mecánicas, lo que las hace adecuadas para una variedad de aplicaciones:

- A2-50:Ideal para aplicaciones flexibles y de bajo estrés y es la opción más rentable.

- A2-70:El grado más comúnmente utilizado, popular en sujetadores como pernos y tuercas debido a su equilibrio entre resistencia y asequibilidad.

- A2-80:Ofrece la mayor resistencia con ductilidad reducida, lo que lo hace extremadamente duradero pero también la opción más cara.

A continuación se muestra una tabla que compara los materiales de acero inoxidable A2-50, A2-70 y A2-80 en términos de resistencia a la tracción, costo y otras propiedades clave:

| Propiedades | A2-50 | A2-70 | A2-80 |

| Resistencia a la tracción | ≥500 N/mm² | ≥700 N/mm² | ≥800 N/mm² |

| 0,2% Resistencia al límite elástico | ≥210 N/mm² | ≥450 N/mm² | ≥600 N/mm² |

| Alargamiento | ≥0,6 días | ≥0,4 días | ≥0,3d |

| Aplicaciones | Trabajo ligero como componentes de bajo estrés) | Uso general como sujetadores | Trabajo pesado como piezas de automóviles |

| Coste | Bajo | Moderado | Alta |

Composición del acero inoxidable A2

| Elemento | Cr | Ni | C | Mn | P | S | Si | N |

| wt% | 18.0 – 20.0 | 8.0 – 10.5 | ≤ 0.08 | ≤ 2.0 | ≤ 0.045 | ≤ 0.03 | ≤ 1.0 | ≤ 0.10 |

Propiedades mecánicas del acero inoxidable A2

| Propiedad | Valor |

| Resistencia a la tracción | 515 - 740 MPa |

| Límite elástico | 205 MPa (min) |

| Dureza Brinell (HB) | 123 - 201 HB |

| Dureza Rockwell (HRC) | 70 - 88 HRC |

| Dureza Vickers (HV) | 129 - 200 HV |

| Alargamiento | 40% (en 50 mm) |

| Módulo elástico | 193 GPa |

Propiedades físicas del acero inoxidable A2

| Propiedad | Valor típico (métrico) | Valor típico (Imperial) |

| Densidad | 7,75 g/cm³ | 0,280 lb/pulg³ |

| Punto de fusión | 1,480°C | 2,696°F |

| Conductividad térmica | 24,9 W/m-K | 173 BTU-in/hr-ft²-°F |

| Expansión térmica | 10,2 µm/m-°C | 5,7 µin/in-°F |

| Conductividad eléctrica | 1,25 x 10⁶ S/m | 2.15% IACS |

- ¿Es magnético el acero inoxidable A2?

En estado recocido, el acero inoxidable A2 no es magnético. Pero puede ser ligeramente magnético cuando se trabaja en frío o se suelda. Esto es importante en aplicaciones en las que las propiedades magnéticas son un factor importante.

Rendimiento del acero inoxidable A2

Excelente resistencia a la corrosión

El acero inoxidable A2 contiene un alto contenido de cromo. Por ello, su resistencia a la corrosión es excelente. Esto lo hace adecuado para entornos en los que el material está expuesto a ácidos, humedad y álcalis. Es adecuado para aplicaciones como equipos de cocina, recipientes para productos químicos y elementos arquitectónicos.

Limitación

No es adecuado para entornos marinos o aplicaciones ricas en cloruro. Debido a la susceptibilidad a las picaduras y al agrietamiento por corrosión bajo tensión, para estos entornos se recomiendan aceros inoxidables de mayor calidad, como el A4 (316).

Resistencia moderada al calor

El acero inoxidable A2 puede soportar temperaturas de funcionamiento continuo de hasta 870 °C y exposición a corto plazo hasta 925 °CSu rendimiento lo hace adecuado para aplicaciones que implican una exposición moderada al calor, como tuberías industriales, utensilios de cocina e intercambiadores de calor.

Limitación

Experiencias en acero inoxidable A2 precipitación de carburo entre 425 °C y 870 °C, reduciendo la resistencia a la corrosión en las zonas soldadas. Su resistencia también disminuye por encima 500°C, lo que limita su uso en aplicaciones de alto estrés y alta temperatura.

Resistencia moderada

El acero inoxidable A2 ofrece una resistencia moderada, con un rango de tensión de 500 a 750 N/mm², adecuado para uso estructural e industrial. Equilibra la durabilidad y la ductilidad.

Limitación

No es ideal para aplicaciones de alta resistencia o de calor intenso. debido a su composición de aleación y limitaciones de rendimiento a temperaturas elevadas.

Facilidad de moldeo

El acero inoxidable A2 es muy maleable, lo que permite moldearlo y darle forma con facilidad. Es ideal para procesos de fabricación que requieran doblar, estampar o dar formas complejas al material.

Resistencia al frío

El acero inoxidable A2 conserva su resistencia a temperaturas muy bajas, soportando condiciones de hasta -196°C (-321°F). Es útil para aplicaciones criogénicas y otros entornos que requieren una gran tenacidad.

Excelente soldabilidad

El acero inoxidable A2 es muy soldable debido a su microestructura austenítica. Es adecuado para las técnicas de soldadura más comunes, incluidas las soldaduras TIG, MIG y por resistencia, sin necesidad de tratamiento térmico posterior a la soldadura en la mayoría de los casos.

Sin embargo, se necesitan precauciones para evitar la precipitación de carburo en la zona afectada por el calor (ZAT) a temperaturas entre 425 °C y 870 °C.

Versatilidad estética

El acero inoxidable A2 puede pulirse hasta conseguir un acabado liso y reflectante, lo que lo convierte en una opción atractiva para aplicaciones visibles o decorativas.

- ¿Es el A2 fácil de afilar?

Sí, el acero inoxidable A2 es relativamente fácil de afilar porque su dureza está equilibrada con una estructura de grano fino, lo que ayuda a lograr un borde afilado sin excesiva dificultad. El acero A2 puede ser un buen cuchillo.

¿Para qué se utiliza el acero inoxidable A2?

El acero inoxidable A2 es el más utilizado en la producción de elementos de fijación. A continuación, se presentan los principales campos de aplicación del acero inoxidable A2.

| Aplicación | Utiliza | Propiedades |

| Alimentación y bebidas | Equipamiento de cocina, tanques de almacenamiento | Resistente a la corrosión, higiénico |

| Construcción y arquitectura | Fachadas de edificios, barandillas | Duradero, estético |

| Automoción | Sistemas de escape, embellecedores | Resistente al calor y a la corrosión |

| Equipamiento médico | Instrumentos y dispositivos quirúrgicos | No reactivo, esterilizable |

| Procesado químico | Depósitos, tuberías | Resistente a ácidos y álcalis |

Formas comunes de productos de acero inoxidable A2

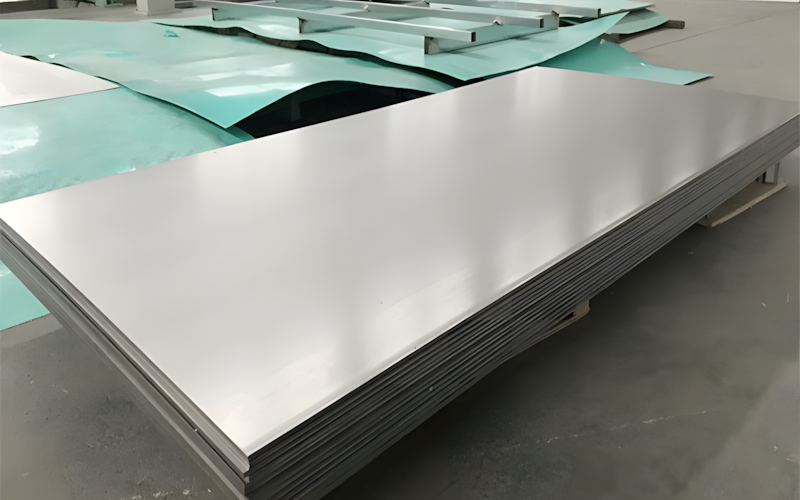

Hojas y placas

El acero inoxidable A2 se suele laminar en láminas finas o placas gruesas, disponibles en varias dimensiones. Su superficie lisa es fácil de limpiar y mantener, lo que lo hace ideal para aplicaciones higiénicas y de calidad alimentaria.

- Fabricación de equipos de cocina, encimeras y fregaderos.

- Se utiliza en maquinaria industrial para cerramientos y paneles estructurales.

Barras y varillas

El acero inoxidable A2 se produce en forma de barra redonda, cuadrada o plana para fabricar componentes de precisión. Ofrece una buena combinación de maquinabilidad y resistencia a la corrosión, lo que lo hace confiable para trabajos de precisión.

- Mecanizado en ejes, pasadores y engranajes en ingeniería mecánica.

- Se utiliza en elementos decorativos como barandillas y tiradores.

Tubos y tuberías

Las formas tubulares de acero inoxidable A2, incluidas las tuberías soldadas y sin costura, están ampliamente disponibles. Sus propiedades anticorrosivas y no magnéticas son adecuadas para aplicaciones de tuberías no críticas.

- Sistemas de plomería en edificios residenciales y comerciales.

- Los sistemas de escape de automóviles requieren una resistencia moderada a la corrosión.

Cables

Los alambres de acero inoxidable A2 se fabrican en diversos diámetros y formas, como bobinas o tramos rectos. Su alta resistencia, resistencia al desgaste y excelente flexibilidad lo hacen ideal para usos dinámicos o de alta precisión.

- Formado en malla de alambre para filtración, cercado o refuerzo.

- Se utiliza para resortes en sistemas mecánicos o equipos de precisión.

Diferencias entre acero inoxidable A2, A4 y A8

Según la norma ISO 3506, inoxidable austenítico Los aceros se clasifican como A1, A2, A3, A4, A5 y A8. Entre estos, los A2, A4 y A8 son los más utilizados, con Acero inoxidable A2 siendo el más común debido a su excelente versatilidad y resistencia a la corrosión.

A4 frente a A2 o 316 frente a 304

El acero inoxidable A2 ofrece una buena resistencia a la corrosión en entornos cotidianos, pero es menos eficaz en zonas con alto contenido en cloruros. El acero inoxidable A4 resiste mejor los cloruros y los ácidos. Es más caro que el A2.

A2 se utiliza en aplicaciones generales como equipos de cocina y estructuras interiores. A4 se prefiere para entornos más duros, como entornos marinos y plantas químicas.

A8 contra A2

El acero inoxidable A8 ofrece una excelente resistencia al desgaste pero una menor resistencia a la corrosión en comparación con el A2.

El A8 es extremadamente duradero, pero más difícil de trabajar y menos dúctil. El acero inoxidable A2 es más fácil de conformar y soldar.

El A2 se utiliza en utensilios de cocina, elementos de fijación y estructuras de interior. La A8 se utiliza en aplicaciones de gran desgaste, como herramientas de corte y maquinaria industrial.

Acero inoxidable A2 frente a 18-8

Acero inoxidable A2 y Acero inoxidable 18-8 son esencialmente iguales en términos de composición. “18-8” es una descripción general para este tipo de acero inoxidable, mientras que “A2” es una designación europea específica, comúnmente utilizada en sujetadores.

Productos de acero inoxidable A2 de alta calidad

Si está buscando productos de alta calidad que cumplan con las especificaciones y tengan un rendimiento constante para su producción de sujetadores u otros productos, SteelPro Group ofrece un rendimiento uniforme y superior. Alambre de acero inoxidable A2, verjay más, junto con una variedad de tratamientos de superficie y opciones de personalización.

Nuestro objetivo es ayudar a que su proyecto tenga éxito en cada paso con nuestros productos de alta calidad. Confíe en SteelPro Group para brindarle la excelencia que necesita para una fabricación confiable y eficiente.

Contacte con nosotros

Para cualquier pregunta o petición, no dude en dejarnos un mensaje aquí. Le responderemos lo antes posible.

- Calidades de acero inoxidable

- Acero inoxidable serie 300

- Acero inoxidable 303

- Acero inoxidable 304

- Acero inoxidable 305

- Acero inoxidable 308

- Acero inoxidable 316

- Acero inoxidable 316N

- Acero inoxidable 409

- Acero inoxidable 410

- Acero inoxidable 416

- Acero inoxidable 420

- Acero inoxidable 430

- Aceros inoxidables 410HT y 410L

- Acero inoxidable 410S

- Acero inoxidable 440

- Acero inoxidable 436

- Acero inoxidable 301

- Acero inoxidable 201

- Acero inoxidable 202

- Acero inoxidable 444

- Acero inoxidable 405

- Acero inoxidable 302

- Acero inoxidable 309

- Acero inoxidable 314

- Acero inoxidable 321

- Acero inoxidable 347

- Acero inoxidable 408

- Acero inoxidable 422

- Acero inoxidable 431

- Acero inoxidable 434

- Acero inoxidable 414

- Acero inoxidable 430FR

- Acero inoxidable 13-8 PH

- 317 | Acero inoxidable 317L

- Acero inoxidable 616

- Acero inoxidable 630

- Acero inoxidable 904L

- Acero inoxidable A2

- Acero inoxidable 304 frente a 304L

- Acero inoxidable 304 VS 316

- Acero inoxidable 304 frente a 409

- Acero inoxidable 304 frente a 430

- Acero inoxidable 410 frente a 304

- 18/0 vs 18/10

- Acero inoxidable 18/0

- Acero inoxidable 18/8

- Acero inoxidable 18/10

Comparaciones

Mantenimiento