Contents

ASTM A6 Tool Steel: Properties, Heat Treat And Uses

- John

A6 tool steel excels in applications requiring precision, toughness, and dimensional stability. Commonly used for blanking dies, forming tools, and molds. This article delves into its properties, heat treatment, and diverse applications to show why A6 is a trusted choice.

What Is A6 Tool Steel?

A6 tool steel is a medium-alloy, air-hardening cold work tool steel known for dimensional stability, toughness, and moderate wear resistance. A6 is used for blanking dies, forming tools, and plastic molds, where precision and thermal fatigue resistance are critical. Hardened A6 achieves 61-62 HRC, with greater toughness than wear-resistant alloys like D2.

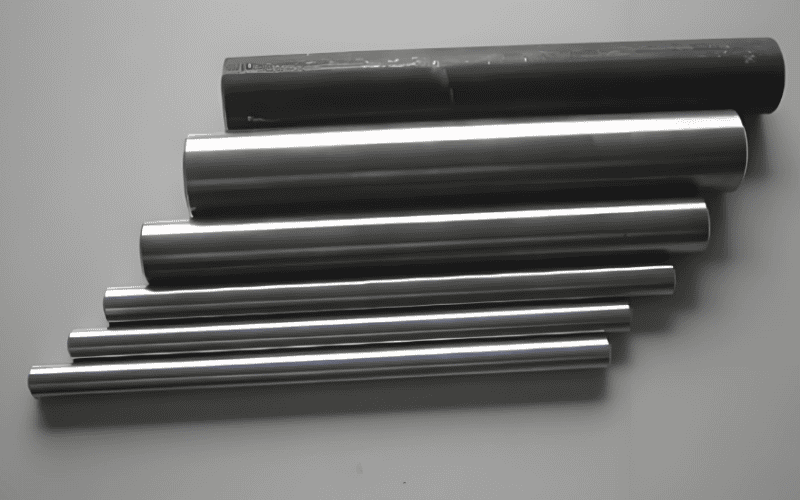

SteelPro Group provides A6 tool steel, equivalent to UNS T30106 and conforming to ASTM A681 standards. Common forms include A6 tool steel round bars, flat bars and plates.

Chemical Composition of A6 Tool Steel

A6 tool steel combines moderate carbon (C) for hardness with chromium (Cr) and molybdenum (Mo) for strength and heat resistance. Manganese (Mn) adds toughness, while low phosphorus (P) and sulfur (S) ensure cleanliness.

The table below outlines its chemical composition.

| Element | Composition (%) |

| Carbon (C) | 0.65 – 0.75 |

| Chromium (Cr) | 1.05 |

| Iron (Fe) | 94, as balance |

| Manganese (Mn) | 2.15 |

| Molybdenum (Mo) | 1.05 |

| Phosphorus (P) | ≤ 0.030 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.030 |

Mechanical Properties of A6 Tool Steel

A6 tool steel exhibits high hardness and wear resistance, coupled with good toughness and moderate machinability, making it ideal for applications requiring durability and precision.

The table below outlines the specific mechanical properties for reference.

| Property | Value (Metric) | Value (Imperial) |

| Hardness (Rockwell C) | 61 – 62 | 61 – 62 |

| Elastic Modulus | 200 GPa | 29000 ksi |

| Bulk Modulus | 160 GPa | 23200 ksi |

| Shear Modulus | 77.0 GPa | 11200 ksi |

| Poisson’s Ratio | 0.3 | 0.3 |

| Machinability | 65 % | 65 % |

- Machinability is based on carbon tool steel.

- Shear modulus is estimated from the elastic modulus.

Physical Properties of A6 Tool Steel

A6 tool steel is characterized by a high density, excellent thermal conductivity, and a stable coefficient of thermal expansion, ensuring dimensional reliability in varying temperatures. Its specific heat and electrical resistivity further contribute to its suitability for high-performance industrial applications.

The table below summarizes its key physical properties for reference.

| Property | Value (Metric) | Value (Imperial) |

| Density | 7.83 g/cm³ | 0.283 lb/in³ |

| Specific Gravity | 7.83 | 7.83 |

| Modulus of Elasticity | 207 GPa | 30 x 10³ ksi |

| Thermal Expansion Coefficient | 11.5 x 10⁻⁶ /°C (20-100°C) | 6.39 x 10⁻⁶ /°F (68-212°F) |

| Thermal Conductivity | 24.9 W/m·K | 172.7 BTU·in/ft²·h·°F |

| Specific Heat Capacity | 460 J/kg·K | 0.11 BTU/lb·°F |

| Electrical Resistivity | 0.00065 Ω·cm | 25.6 μΩ·in |

- The values provided are typical for A6 tool steel and may vary based on specific processing and treatment conditions.

A6 Tool Steel Fabrication And Heat Treatment

Heat treatment tailors A6 tool steel’s hardness, toughness, and stability for demanding applications like precision tools and wear-resistant components.

At SteelPro Group, we supply A6 tool steel in annealed, pre-hardened, or fully treated conditions, ready to meet your specific requirements. Below is a detailed guide to its heat treatment process.

Forging

A6 tool steel should be forged at a temperature range of 900-1150°C (1650-2100°F). Annealing is mandatory after forging because forging introduces internal stresses and irregular grain structures that can compromise mechanical properties.

Annealing

Annealing is required after hot working or prior to re-hardening to restore ductility and optimize machinability. The hardness after this process typically ranges between 197-229 HB.

The temperature should be maintained at 800-850°C (1475-1560°F). Once at the target temperature, soak the steel for 1 hour per 25.4 mm (1 inch) of thickness to ensure the core and surface reach uniform conditions. After soaking, cool the steel in a furnace at a controlled rate of 15-20°C (27-36°F) per hour until it reaches approximately 650°C (1200°F). From this point, allow the steel to air cool to room temperature.

Hardening

- Austenitizing

Heat the steel to 815-870°C (1500-1600°F). Hold the steel at this temperature for 30 minutes per 25.4 mm (1 inch) of thickness to ensure thorough transformation.

- Quenching

Thin sections (<25.4 mm or 1 inch) should be air-quenched at approximately 800°C (1475°F). Thicker sections (≥25.4 mm or 1 inch) may require oil quenching starting at 815-870°C (1500-1600°F) for adequate cooling rates. The choice of quenching medium helps prevent cracking while achieving sufficient hardness.

Tempering

Tempering is performed immediately after quenching to reduce brittleness and improve toughness. The steel should be heated to the desired tempering temperature and held for 1 hour per 25.4 mm (1 inch) of thickness.

The optimal tempering range for balancing hardness and toughness is 150-315°C (300-600°F). This range is suitable for most applications requiring moderate toughness and wear resistance. For applications demanding higher toughness, tempering at 425-540°C (797-1000°F) can be used, though this reduces hardness slightly.

| Temperature (°C) | Temperature (°F) | Hardness (HRC) |

| 95 | 203 | 61 – 62 |

| 150 | 302 | 60 – 61 |

| 205 | 401 | 58 – 59 |

| 260 | 500 | 56 – 57 |

| 315 | 599 | 55 – 56 |

| 425 | 797 | 52 – 53 |

| 480 | 896 | 50 – 51 |

| 540 | 1004 | 48 – 49 |

Optimizing A6 Tool Steel

A6 tool steel can undergo cryogenic treatment after quenching or extended tempering cycles during heat treatment to enhance performance for specific applications.

- Cryogenic Treatment: Converts retained austenite at -196°C (-320°F), improving wear resistance and dimensional stability. Ideal for precision tools.

- Extended Tempering: Multiple tempering cycles reduce austenite and improve hardness, offering a cost-effective alternative.

A6 Tool Steel Product Forms

The table below outlines the typical product forms and size ranges available for A6 tool steel, including round bars, flat bars, plates, and sheets.

| Product Form | Sizes (Metric) | Sizes (Imperial) |

| Round Bars | Diameters: 12.7 – 203.2 mm | Diameters: 0.5 – 8 in |

| Flat Bars | Thickness: 12.7 – 101.6 mm | Thickness: 0.5 – 4 in |

| Width: 38.1 – 152.4 mm | Width: 1.5 – 6 in | |

| Plates | Thickness: 12.7 – 101.6 mm | Thickness: 0.5 – 4 in |

| Sheets | Thickness: 0.8 – 6.35 mm | Thickness: 0.03 – 0.25 in |

We provide A6 tool steel with exceptionally tight tolerances, ensuring precision and reliability for critical applications. If your requirements exceed the standard size ranges listed below, we can accommodate custom dimensions to meet your specific needs.

A6 Tool Steel Applications

A6 tool steel combines moderate wear resistance, excellent toughness, and dimensional stability, making it ideal for precision tools and components. Its air-hardening nature minimizes distortion during heat treatment, ensuring reliability in demanding industrial applications.

- Blanking and Forming Dies: High-precision operations requiring sharpness and resistance to deformation.

- Trim Dies: Removing excess material during production, leveraging toughness to resist wear.

- Mandrels: Supporting workpieces during machining or forming with dimensional stability.

- Plastic Injection Molding Tooling: Maintaining accuracy and resisting thermal fatigue in molds and dies.

- Dowel Pins: Precision alignment in assemblies with wear resistance and stability.

- Shear Knives: Cutting tasks requiring sharp edges and consistent wear performance.

- Gauges: Measurement tools demanding high dimensional accuracy and durability.

What Is The Difference Between A2 And A6 Tool Steel?

A2 offers higher wear resistance due to its higher carbon content, ideal for cutting tools. A6 provides greater toughness and less distortion during heat treatment, making it better for impact tools like forming dies and molds.

Elevating Your A6 Tool Steel Experience

At SteelPro Group, we don’t just provide materials—we deliver solutions. From bars and plates to sheets and rounds, our A6 tool steel products are crafted to meet the highest industry standards.

We don’t stop at providing raw materials. Our comprehensive processing services are designed to help you maximize the potential of A6 steel for your applications, including heat treatment, custom machining, surface grinding and polishing

With SteelPro Group, you don’t just get A6 tool steel—you get a partner committed to your success.