Contents

What is H13 Tool Steel? Explained From Pro H13 Supplier

- John

We are experts in H13 tool steel, providing solutions for high-performance mold production. As a global manufacturer, we are glad to help you learn more about H13 high-speed tool steel.

What Is H13 Tool Steel?

H13 tool steel is a high-performance steel designed for high-temperature environments. It belongs to the hot work tool steel family, which means it’s built to withstand extreme heat without losing strength. The “H” in H13 indicates it is part of the hot work category. The “13” refers to the specific grade within this category. This grade is chosen for its toughness, heat resistance, and wear resistance.

H13 is also a great shock-absorbing tool steel. The alloy mix of chromium, molybdenum, and vanadium gives it strength and resilience. It performs well in environments where tools are subjected to repeated heating and cooling cycles, like die-casting, injection molding, and forging.

H13 Tool Steel Applications

H13 is used in a wide range of industries, from die-casting molds for aluminum and zinc alloys to injection molding inserts for plastic parts. It’s also used in forging dies, extrusion dies, and hot-shear blades.

H13 Tool Steel Performance Improvement

H13 can be treated with nitriding. This process forms a layer of nitrides on the steel surface, making it more abrasion-resistant and extending the life of the tool.

Additionally, remelting processes like electro-slag remelting (ESR) and vacuum arc remelting (VAR) are used to improve the chemical homogeneity and microstructure of the steel. These methods help reduce impurities and increase fatigue resistance, improving H13’s overall performance.

What Is The Difference Between H11 and H13 Tool Steel?

H11 and H13 are both hot work tool steels. H11 has a lower chromium content (5%) than H13 (6%). H13 is more suited for high-temperature wear resistance, while H11 provides slightly better toughness in more demanding shock-loading conditions.

What Is The Difference Between H13 and H14 Tool Steel?

H13 and H14 are both hot work tool steels, with H14 containing slightly more chromium (7% vs. 6% in H13). This gives H14 better wear resistance and improved performance in high-temperature environments. H13 excels in toughness and thermal fatigue resistance.

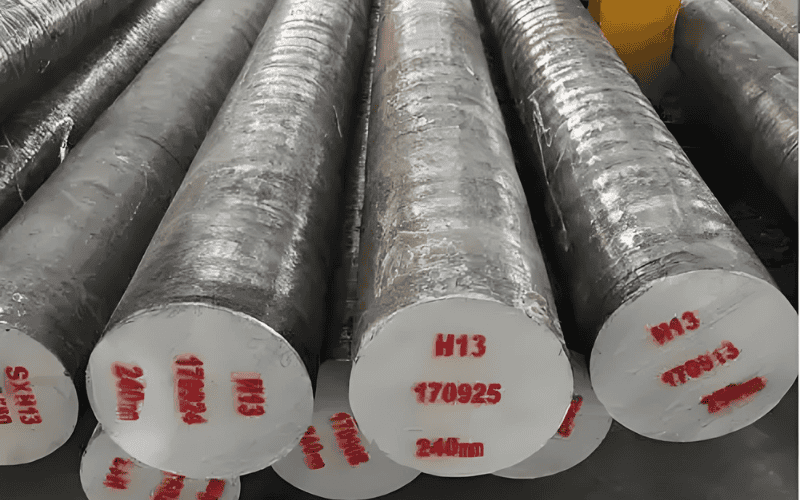

H13 Steel Products Options and Supply

From bars and plates to custom sizes, our H13 steel is available in different forms to ensure the right fit for your application. SteelPro Group also offers ESR and VAR options for customers who require superior material consistency and enhanced mechanical properties.

We know every order is unique. Whether you need a small amount or a large order, we make sure to deliver quickly and provide you with high-quality products that fit your needs.