Contents

L2 Low-alloy Special-purpose Tool Steel | T61202 | 1.2235

- John

At SteelPro Group, we are a trusted supplier of L2 tool steel, offering a variety of forms including plates, bars, and rods. With extensive experience in the steel industry, we provide tailored solutions to meet your specific needs, ensuring high-quality materials and reliable delivery.

What Is L2 Tool Steel?

L2 steel is an oil-hardening tool steel that comes in medium-carbon (0.45%-0.65%) and high-carbon (0.65%-1.10%) versions. It is recognized for its strength, abrasion resistance, and excellent hardenability, due to the inclusion of chromium and vanadium. L2 steel is commonly used for tools such as punches, dies, spindles, and cold-heading dies.

What is Equivalent to L2 Steel?

L2 tool steel has equivalent grades in various international standards, including:

- UNS T61202 (United States)

- JIS G4404 SKT3 (Japan)

- DIN 1.2210 (Germany)

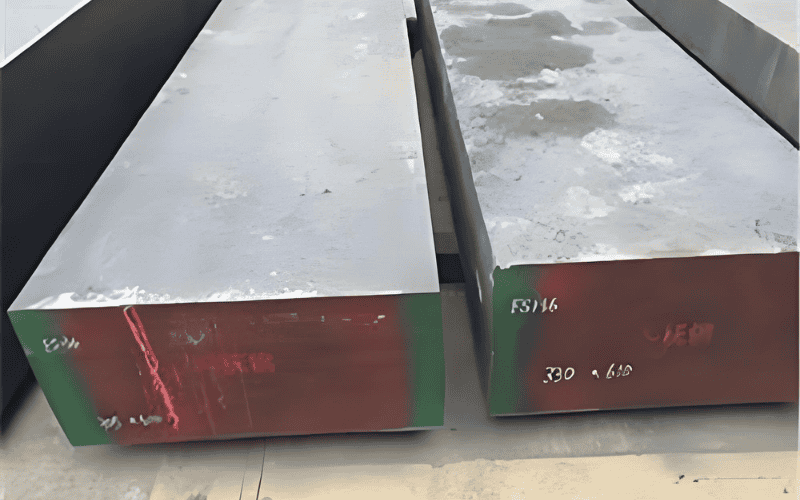

L2 Tool Steel Products Forms And Supply Range

We offer L2 tool steel in standard forms like plates, bars, and rods with various size options. In addition to these, we provide custom solutions to meet specific size or shape requirements, ensuring you get exactly what you need for your projects.

| Product Form | Size Range (Metric) | Size Range (Imperial) |

| Round Bars | Diameter: 10 mm to 300 mm | Diameter: 0.39 in to 11.81 in |

| Square Bars | Side length: 10 mm to 200 mm | Side length: 0.39 in to 7.87 in |

| Flat Bars | Thickness: 5 mm to 100 mm | Thickness: 0.20 in to 3.94 in |

| Width: 20 mm to 300 mm | Width: 0.79 in to 11.81 in | |

| Plates | Thickness: 10 mm to 100 mm | Thickness: 0.39 in to 3.94 in |

| Width: 150 mm to 3000 mm | Width: 5.91 in to 118.11 in | |

| Length: 500 mm to 6000 mm | Length: 19.69 in to 236.22 in | |

| Sheets | Thickness: 1 mm to 6 mm | Thickness: 0.04 in to 0.24 in |

| Width: 200 mm to 1500 mm | Width: 7.87 in to 59.06 in | |

| Length: 500 mm to 3000 mm | Length: 19.69 in to 118.11 in | |

| Tooling Rounds | Diameter: 10 mm to 150 mm | Diameter: 0.39 in to 5.91 in |

L2 Tool Steel Chemical Composition

| Element | Composition |

| Carbon (C) | 0.45 – 1.10% |

| Silicon (Si) | 0.1 – 0.5% |

| Manganese (Mn) | 0.1 – 0.9% |

| Phosphorus (P) | ≤ 0.03% |

| Sulfur (S) | ≤ 0.03% |

| Chromium (Cr) | 0.7 – 1.2% |

| Molybdenum (Mo) | ≤ 0.25% |

| Vanadium (V) | 0.1 – 0.3% |

| Nickel + Copper (Ni + Cu) | ≤ 0.75% |

L2 Tool Steel Physical Properties

| Property | Metric Value | Imperial Value |

| Density | 7.85 g/cm³ | 0.284 lb/in³ |

| CTE | 11.3 µm/m·K | 6.28 µin/in-°F |

| Thermal Conductivity | 26.5 W/m·K | 18.3 BTU/hr·ft·°F |

| Specific Heat | 0.46 J/g·K | 0.11 BTU/lb·°F |

| Melting Point | 1425 – 1470°C | 2600 – 2678°F |

L2 Tool Steel Mechanical Properties

| Property | Metric Value | Imperial Value |

| Hardness (HRC) | 30 – 54 | 30 – 54 |

| Tensile Strength, Ultimate | 710 – 2000 MPa | 103,000 – 290,000 psi |

| Tensile Strength, Yield | 510 – 1790 MPa @ Strain 0.2% | 74,000 – 260,000 psi @ Strain 0.2% |

| Elongation at Break | 5.0 – 25 % | 5.0 – 25 % |

L2 Tool Steel Heat Treatment

At SteelPRO, we offer L2 tool steel in both annealed and pre-hardened conditions, giving you flexibility based on your specific needs.

Preheating

Gradually heat the L2 tool steel to 649°C (1200°F) to prevent thermal shock during the subsequent heating stages.

Austenitizing

Raise the temperature of the steel to 857°C (1575°F) for austenitizing. Maintain this temperature for 5 to 15 minutes, depending on the thickness of the material, to ensure the steel achieves a uniform structure before quenching.

Quenching

After austenitizing, cool the steel in oil. Oil is selected because it provides a controlled cooling rate, reducing the risk of cracking while ensuring the desired hardness is achieved.

Tempering

Temper the steel at 204°C (400°F) for 1 hour. This step reduces brittleness by allowing some of the internal stresses from the quenching process to dissipate. The hardness after tempering will be approximately RC 53.

L2 Tool Steel Applications

- Cold and Warm Forging Dies

- Blanking Punches and Shearing Dies

- Cold Rolling Rollers

- End Mills

- Drill Bits

- Injection Molds

- Machining Fixtures and Jigs

- Chisels and Cutting Edges

Unlock Precision with Premium L2 Tool Steel

At SteelPro Group, we specialize in L2 tool steel, offering a wide range of sizes and shapes to meet your specific needs. In addition to L2, we also provide D2 tool steel plates, bars, and more.

Our services include precision cutting, bending, machining, welding, and fabrication, ensuring we can deliver any custom solution you require. Reach out to us today to discuss how we can support your projects with high-quality materials and expert services.