Contents

Galvanized Steel DX51D | 1.0917: Definition, Properties, Uses

- John

DX51D galvanized steel is a popular material used in various industries as its Z coating offers excellent protection against rust. In this article, we will explore its composition, properties, and other key details.

What is DX51D?

DX51D is a grade of hot-dip galvanized low-carbon steel under EN 10346, which is primarily used for cold-forming applications. It offers excellent corrosion resistance and flexibility. It is usually used in construction, automotive manufacturing, and household appliances due to its versatility.

Breaking Down the DX51D Designation

- “D” – Cold Forming Steel

- “X” – Unspecified Rolling State. It can be either hot-rolled or cold-rolled.

- “51” – Steel Grade Serial Number. The higher numbers (e.g., 52, 53, 54) indicate better formability.

- “D” – Hot-Dip Galvanized Coating

- “+Z, +ZF, etc.” – Coating Types.

What Is the Difference Between DX51D and DX52D?

DX51D and DX52D are both hot-dip galvanized steels used for cold forming. DX52D has higher ductility and better elongation than DX51D. DX52D is more suitable for complex forming processes that require greater flexibility, while DX51D is used for standard forming applications.

DX51D Equivalent Steel Grade and Material Number

| Region | Standard | Equivalent Grade |

| Europe | EN 10346 | DX51D |

| United States | ASTM A653 | A653/A653M Class B |

| Japan | JIS G3302 | SGCC |

| China | GB/T 2518 | Q195/Q235 |

| India | IS 277 | IS 277 |

| German | DIN EN 10130, DIN 1623 | 1.0322, 1.0335, DC01, DC04, DD11, DD13, St12, St14, St22, StW24, USt3, USt4 |

Material Number

1.0917: Material number based on the European material standard EN 10027-2.

1.0226: Confirmed as the most commonly used material number for DX51D under the EN 10346 standard

DX51D Steel Chemical Composition

| C | Si | Mn | P | S | Ti |

| max 0.18 | max 0.5 | max 1.2 | max 0.12 | max 0.045 | max 0.3 |

DX51D Steel Mechanical Property

| Mechanical Property | Value | Value |

| Tensile Strength | 270-500 MPa | 39,200-72,500 psi |

| Elongation | ≥ 22% | ≥ 22% |

DX51D Steel Characteristics

Corrosion Resistance

The zinc coating offers strong protection against rust, making it ideal for outdoor and harsh environments.

Formability and Ductility

Low carbon content allows DX51D to be easily shaped, bent, or stamped, making it useful for cold-forming applications.

Durability

Its combination of zinc coating and mechanical strength ensures long-lasting performance, even in tough conditions.

Flexibility

DX51D steel can be used in various manufacturing processes due to its ability to accommodate both hot-dip galvanizing and further surface treatments.

Weldability

While the zinc coating requires special attention during welding, DX51D can be welded effectively using the right methods.

DX51D Steel Applications

In the construction industry, DX51D is commonly used for roofing, wall cladding, and structural elements due to its strength and durability, especially in outdoor environments.

In automotive manufacturing, its flexibility and corrosion resistance make it ideal for car body panels and other components.

In household appliances, its moisture resistance is crucial for items like washing machine drums, refrigerator panels, and air conditioning units, where exposure to water is frequent.

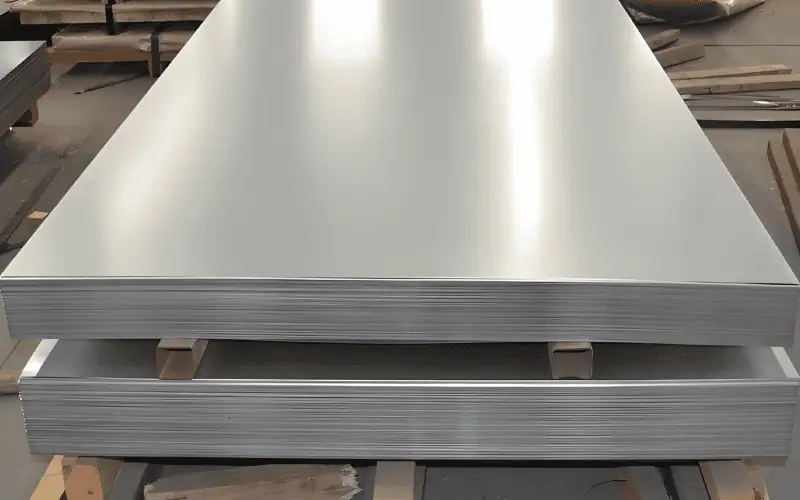

DX51D Steel Product Forms and Specifications

SteelPro Group is a reliable supplier of DX51D PPGI coils, DX51D galvanized steel coils, DX51D galvanized sheets, and other high-quality DX51D products like pipe, tube, and roofing sheets. We provide extensive customization options.

| Product Form | Thickness | Width | ||

| mm | inches | mm | inches | |

| DX51D Sheets | 0.3 – 3.0 | 0.012 – 0.118 | Up to 1520 | Up to 59.8 |

| DX51D Coils (Cold-Rolled) | 0.2 – 6.0 | 0.008 – 0.236 | 600 – 1500 | 23.6 – 59.1 |

| DX51D Coils (Hot-Rolled) | 3.0 – 12.0 | 0.118 – 0.472 | 600 – 2000 | 23.6 – 78.7 |

DX51D Steel Coating Types

DX51D Z (Zinc Coating)

This is the most widely used coating, providing excellent rust protection through a layer of pure zinc. Ideal for outdoor structures, it offers a reliable barrier against moisture.

- Thickness: 5-42 μm.

- Applications: Roofing, cladding, and automotive parts.

DX51D ZF (Zinc-Iron Alloy Coating)

Also known as Galvannealed coating, this zinc-iron layer allows better paint adhesion. While its corrosion resistance is slightly lower than pure zinc, the ZF coating offers excellent surface quality and formability.

- Thickness: 5-12 μm.

- Applications: Painted automotive parts, and appliances.

DX51D ZA (Zinc-Aluminum)

A mix of 95% zinc and 5% aluminum, this coating offers enhanced corrosion resistance, especially in industrial and coastal environments.

- Thickness: 5-33 μm.

- Applications: Coastal structures, cladding.

DX51D AZ (Aluminum-Zinc)

This combination of 55% aluminum and 43.5% zinc delivers superior heat and corrosion protection, extending the steel’s lifespan in extreme conditions.

- Thickness: 9-33 μm.

- Applications: HVAC, roofing, industrial machinery.

DX51D ZM (Zinc-Magnesium)

Adding magnesium to zinc improves both the corrosion resistance and formability, making it ideal for harsh environments like marine and industrial settings.

- Thickness: 4-20 μm.

- Applications: Marine structures, automotive parts.

| Coating Example | Typical Thickness (μm) | Minimum Total Coating Mass (Both Surfaces, g/m²) |

| Z100 | 7 | 100 |

| Z200 | 14 | 200 |

| Z275 | 20 | 275 |

| ZF100 | 7 | 100 |

| ZA130 | 10 | 130 |

| AZ150 | 20 | 150 |

| ZM120 | 9 | 120 |

What is DX51D Z275?

DX51D Z275 is a hot-dip galvanized steel grade. “Z275” indicates the zinc coating weight of 275 grams per square meter (total on both sides). This zinc coating enhances corrosion resistance, making it ideal for outdoor applications like roofing and wall cladding.

DX51D Steel Surface Treatment

SteelPro Group provides DX51D steel with various surface treatments, including chromate (+C, +S), phosphate (+P, +Q, +T, +V), oiling (+O), and untreated (+M). If you’re unsure which treatment suits your application best, we are ready to help you make the right choice.

Chromate Treatment (+C, +S) – Enhanced Corrosion Resistance

- +C (Chromate-Treated): Standard anti-corrosion treatment, ideal for outdoor applications.

- +S (Chromate-Treated & Oiled): Adds a protective oil coating over chromate treatment for extra rust prevention during transportation and storage.

Best For:

✔ Roofing sheets, wall panels, and outdoor structures

✔ Components exposed to humidity and environmental factors

Phosphate Treatment (+P, +Q, +T, +V) – Paint-Ready Surface

- +P (Phosphate with Passivation): Enhances paint bonding and moderate corrosion resistance.

- +Q (Phosphate with Passivation & Oiled): Further reduces storage rust risk while keeping excellent paint adhesion.

- +T (Phosphate without Passivation): Basic phosphate coating, suitable for further processing.

- +V (Phosphate without Passivation & Oiled): Adds oil for temporary corrosion protection during transport.

Best For:

✔ Automotive body parts and industrial machinery requiring painting

✔ Household appliances such as refrigerators, ovens, and washing machines

Oiling (+O) – Temporary Rust Protection

- Requires cleaning before painting or welding.

Best For:

✔ DX51D steel that will be stamped, bent, or coated after delivery

✔ Automotive components and metal fabrication

Untreated Surface (+M) – For Custom Processing

- Best choice for manufacturers who apply their own coatings or treatments.

Best For:

✔ Industrial applications requiring immediate painting

✔ Manufacturers applying custom anti-corrosion coatings

DX51D Steel Surface Quality

A: Standard Surface Quality

This grade allows for small imperfections like minor scratches, dents, or unevenness. These surface irregularities do not affect the steel’s mechanical performance or structural integrity. It remains functional for applications where appearance is not a priority.

B: Improved Surface Quality

Improved surface quality has fewer defects and offers a smoother texture than standard grade. It is suitable for parts that may undergo painting or further finishing. The steel surface typically shows fewer visible imperfections, making it more appropriate for use in semi-visible applications.

C: High Surface Quality

High surface quality is almost flawless, designed for products where appearance is essential. The surface is smooth, without visible scratches, dents, or irregularities, ensuring the best results for high-end coatings or decorative applications.

Reliable DX51D Steel Supplier

At SteelPro Group, we don’t just supply DX51D steel—we optimize it for your needs. From custom coatings and precise dimensions to application-specific recommendations, we help you get the most out of every sheet and coil.

Let’s move beyond standard solutions. Tell us your requirements, and we’ll deliver steel that fits—not just in size, but in performance.