Contents

Difference Between Galvanization and Alloying

- John

Galvanization and alloying are two separate processes with unique purposes. Galvanizing means covering the surface of steel with a zinc layer to enhance corrosion resistance. Alloying modifies the intrinsic properties of a metal by blending it with one or more additional elements to form a homogeneous material with enhanced characteristics.

This article will compare galvanization and alloying in several aspects, including their processes, properties, and applications.

Key Differences Between Galvanization and Alloying

Check the table below for an overview of the main differences between galvanization and alloying.

| Aspects | Galvanization | Alloying |

| Metal Structure | No change | Alters |

| Cost | Lower | Higher |

| Process Complexity | Relatively simple | More complex |

| Performance | Adds corrosion resistance | Enhances properties like strength, ductility, and corrosion resistance |

| Application | Outdoor structures, automotive panels, and pipes | High-strength and specialized applications like tools and machinery |

Process of Galvanization vs. Alloying

Galvanization is generally simpler and less costly because it only involves coating the metal surface with zinc. Alloying is more complex and typically more expensive, as it requires melting and combining multiple elements to create a new material with improved properties throughout its structure.

Here’s a detailed explanation of each process:

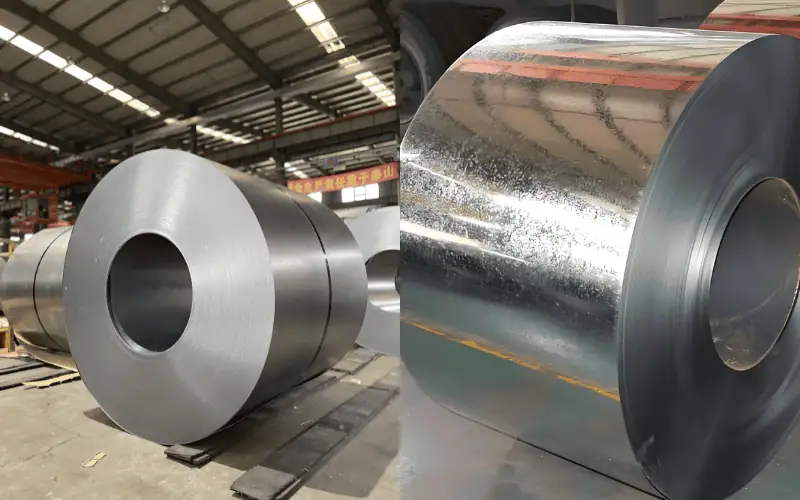

Galvanization

Galvanization protects steel or iron from rust by adding a zinc layer. There are several methods:

- Hot-Dip Galvanization

In this widely used method, cleaned steel is dipped into molten zinc, where a reaction between the zinc and steel forms a series of zinc-iron alloy layers. These layers bond firmly to the steel, creating a robust outer coating. This method provides strong, long-lasting corrosion resistance and is often used for outdoor structures.

- Electro galvanizing

This method uses an electric current to deposit zinc onto the steel surface. The steel acts as a cathode, while zinc ions in the solution are attracted and reduced onto it. Electro galvanizing results in a thinner but smooth zinc layer, often used in applications like automotive body panels, where appearance and uniformity are important.

Alloying

Alloying is a process of combining metals with other elements to alter the metal’s internal structure and properties.

This process is based on principles of atomic interaction, phase transformation, and solid solution.

- Melting and Mixing

In alloying, base metals like iron are melted along with selected alloying elements such as carbon, chromium, or nickel. At high temperatures, these elements mix at the atomic level, creating a new material with enhanced properties.

For example, adding carbon to iron results in steel, which is tougher and more long-lasting than pure iron.

- Solid Solution and Phase Formation

As the mixture cools, the atoms settle into a structured arrangement, either forming a solid solution or distinct phases within the alloy. This atomic structure offers particular properties, such as corrosion resistance or enhanced strength.

For instance, adding chromium to steel forms stainless steel, which is resistant to rust due to the passive oxide layer created by chromium on the metal’s surface.

Does Galvanizing Make a Steel Alloy?

No, galvanizing does not make steel an alloy. It only adds a protective zinc coating on the surface of the steel, without mixing zinc into the steel itself.

Properties of Galvanization vs Alloying

Corrosion Resistance

Alloyed metals generally offer better corrosion resistance compared to galvanized steel.

With alloying, elements like chromium are integrated throughout the entire material, providing internal resistance. Even if the alloyed metal is scratched or worn, this internal resistance remains effective, making alloyed metals more resilient in harsh or high-humidity environments.

In galvanization, the zinc layer only protects the surface. If this protective layer is damaged, the exposed base metal can quickly begin to rust. However, galvanized steel still provides good corrosion resistance in typical outdoor conditions.

Strength and Durability

Alloying offers greater improvements in strength and durability than galvanization.

By altering the internal structure, alloying increases properties like tensile strength and toughness. Alloyed metals, such as high-strength steel, can withstand heavy loads and repeated stress, making them ideal for demanding applications.

In contrast, galvanization does not increase the metal’s strength. The strength and durability of galvanized steel largely depend on its base material. Typically, galvanized steel keeps the original strength of the base steel, which is suitable for structural and outdoor uses. However, it lacks the extra load-bearing and impact resistance that alloyed metals offer.

Maintenance and Lifespan

Alloying generally needs less upkeep and offers a longer service life. This makes it economical in the long run for applications where durability is essential.

Galvanized coatings may require regular inspections because the zinc coating can wear down or become damaged over time, especially in harsh environments. If the coating is damaged, it can often be repaired by applying a zinc-rich paint or spray to restore protection.

Appearance and Finish

Hot-dip galvanized steel often has a rough, industrial look due to its thicker zinc coating, suitable for structural applications. Electro-galvanized steel, with its thinner coating, provides a smoother finish for visible applications.

Alloyed metals, like stainless steel, offer a more refined, uniform appearance. They can be polished to a sleek finish, making them ideal for both functional and decorative purposes where aesthetics matter.

Cost

Galvanization is typically more affordable and simpler than alloying.

The galvanizing process is straightforward, involving a zinc coating that requires minimal equipment and materials. Alloying is more complex, requiring precise mixing of elements and controlled conditions, which drives up costs.

For applications needing basic corrosion protection, galvanization is the cost-effective choice, while alloying is an investment in higher performance.

Different Applications of Galvanization and Alloying

Galvanization

- Construction and Infrastructure

Galvanized steel is popular in roofing, fencing, and outdoor structures. Its zinc coating provides effective rust protection, making it ideal for bridges, guardrails, and utility poles exposed to moderate weather.

- Automotive Industry

Many vehicle parts, like body panels and frames, use galvanized steel. The zinc layer helps prevent rust, especially in areas exposed to moisture, offering a cost-effective way to extend the lifespan of these parts.

- Outdoor Products and Equipment

Galvanized metals are often used in outdoor furniture, playgrounds, and farm tools. The protective layer shields them from moisture and weather, keeping maintenance low and durability high.

Alloying

- High-Stress Structural Components

Alloyed metals are used in building frameworks, bridges, and heavy machinery, where high strength and resilience are essential. These materials withstand high loads and maintain stability over time.

- Automotive and Aerospace Parts

Alloyed metals, such as high-strength steels, are essential in engine parts, gears, and suspension systems. Their durability and resistance to temperature make them reliable under stress.

- Industrial and Chemical Environments

In chemical plants and marine settings, stainless steel and other alloys resist corrosion from chemicals and saltwater. They’re ideal for tanks, pipes, and equipment exposed to harsh environments.

How to Choose Between Galvanization and Alloying

Galvanized steel is ideal for moderate corrosion protection in standard outdoor settings, offering a balance of protection and cost-effectiveness.

Alloyed metals are suited for more intensive use, where structural integrity and consistent performance are essential.

Power Your Projects with Steel Built to Endure

At Steel Pro Group, we provide high-quality alloyed and galvanized steel to meet the unique demands of any project. Whether you need the resilience of alloyed steel or the dependable protection of galvanized steel, we have the right solution. Please get competitive rates and reliable service by checking our quote options.