Contents

ABS Grades A B D E Shipbuilding Steel Plate

- John

The A, B, D, and E grades specified by ABS are structural steel grades used in shipbuilding. A, B, D, and E shipbuilding steel plates are known for their strength, weldability, and toughness in challenging marine environments.

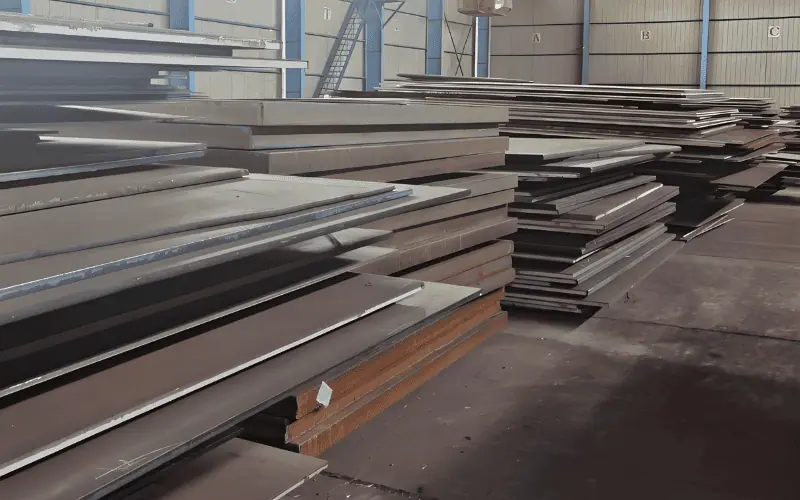

SteelPro Group is a global supplier of premium A, B, D, and E steel plates, offering the finest shipbuilding steel products.

Overview of ABS Grades A, B, D, E Shipbuilding Steel

ABS grades A, B, D, and E are specifically designed for medium to heavy steel plates with thicknesses from 6mm to 40mm. These grades are classified based on their impact toughness at various testing temperatures, ensuring optimal performance in diverse environmental conditions.

Grade A Steel Plate

Designed for general-purpose shipbuilding with no specific impact toughness requirement at 20°C (4°F). Primarily used for bulkheads, frames, and deck plating in interior compartments and superstructures of ships operating in mild conditions.

Grade B Steel Plate

Requires 27 J impact toughness at 0°C (32°F). Suitable for shell plating, longitudinal bulkheads, and hatch coamings in cargo ships, ferries, and container ships operating in temperate environments.

Grade D Steel Plate

Requires 27 J impact toughness at -20°C (-4°F). Commonly used for hulls, keels, and deck structures in ice-class ships, trawlers, and offshore supply vessels operating in cold regions.

Grade E Steel Plate

Requires 27 J impact toughness at -40°C (-40°F). Ideal for icebreakers, polar research vessels, and offshore platforms operating in Arctic waters and extreme cold environments.

A, B, D, E Steel Plate Dimensions Range

We supply ABS grades A, B, D, and E shipbuilding steel plates in various delivery conditions, including TM (Thermo-Mechanical), TMCP (Thermo-Mechanical Control Process), N (Normalized), and NR (Normalized Rolling).

The specific steel plate size ranges are as follows:

| Thickness (mm) | Width (mm) | Length (mm) |

| 6 – 40 (0.24″ – 1.57″) | Up to 3000 (118″) | Up to 12,000 (472″) |

Our advanced production facilities allow us to meet a wide range of dimensional requirements, ensuring that our plates fit diverse shipbuilding and offshore construction needs. We also offer custom steel plates with thicknesses below 6mm with MOQ. For more information, please feel free to contact us.

A, B, D, E Steel Plate Certifications

Our shipbuilding steel plates are certified by major classification societies, including ABS, BV, DNV, GL, LR, and CCS, guaranteeing compliance with strict international standards. Our commitment to quality ensures that every plate meets or exceeds the certification requirements.

In addition to ABS grades A, B, D, E steel plates, we also supply high-strength shipbuilding steel plates, including AH36, DH36, EH36, FH36, AH40, DH40, and EH40.

A, B, D, E Shipbuilding Steel Plate Chemical Composition

| Grade | C (%) | Mn (%) | Al (%) | Si (%) | P (%) | S (%) |

| A | ≤ 0.21 | ≤ 1.3 | ≥ 0.015 | 0.10 – 0.50 | ≤ 0.035 | ≤ 0.035 |

| B | ≤ 0.21 | ≤ 1.3 | ≥ 0.015 | 0.10 – 0.50 | ≤ 0.036 | ≤ 0.035 |

| D | ≤ 0.21 | ≤ 1.3 | ≥ 0.015 | 0.10 – 0.50 | ≤ 0.037 | ≤ 0.035 |

| E | ≤ 0.21 | ≤ 1.3 | ≥ 0.015 | 0.10 – 0.50 | ≤ 0.038 | ≤ 0.035 |

A, B, D, E Shipbuilding Steel Plate Mechanical Composition

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation | Testing Temperature | V-notch Impact Test | ||

| t≤50 | 50<t≤70 | 70<t≤100 | |||||

| A | ≥ 235 | 400 – 520 | ≥22 | 20°C (4°F) | – | 34 J (25 ft-lb) | 41 J (30 ft-lb) |

| B | 0°C (32°F) | 27 J (20 ft-lb) | |||||

| D | -20°C (-4°F) | ||||||

| E | -40°C (-40°F) | ||||||

- “t” represents the thickness of the plate in millimeters (mm).

- The V-notch impact test values listed in the table are measured in the transverse direction.

A, B, D, E Shipbuilding Steel Plate Process

ABS grades A, B, D, and E shipbuilding steel plates are known for their excellent weldability, machinability, and formability, making them suitable for various conventional and advanced processing methods.

These plates can be processed using standard methods such as cutting, welding, bending, and forming, as well as specialized techniques like TMCP and controlled rolling to achieve optimal mechanical properties and surface quality.

SteelPro Group leverages advanced manufacturing expertise to ensure high-quality production of these shipbuilding steel grades. Our specialized processes include:

Micro-Alloying Technology

Through the precise addition of niobium, vanadium, and titanium, we enhance the steel’s grain refinement, improving both its yield strength and toughness. This ensures that the plates can withstand high stress and impact in challenging marine environments.

Controlled Rolling

Our controlled rolling process optimizes grain structure by carefully managing the rolling temperature and deformation stages. This is critical for grades D and E, which require excellent performance at sub-zero temperatures.

TMCP (Thermo-Mechanical Control Processing)

By combining controlled rolling with accelerated cooling, TMCP allows us to produce plates with higher strength and improved toughness, especially in thicker sections. This reduces the need for additional heat treatment, improving production efficiency while maintaining high performance.

Precision Quality Control

We adhere to strict quality standards, conducting ultrasonic testing, impact tests, and dimensional verification on every plate to ensure full compliance with ABS requirements. This rigorous process guarantees reliability and safety for shipbuilding and offshore applications.

Customized A, B, D, and E Steel Plates for Superior Performance

SteelPro Group offers ABS-certified grades A, B, D, and E steel plates with customizable dimensions and advanced processing options.

For customized orders, technical support, or expert guidance, reach out to us. Let SteelPro Group be your trusted partner in building durable, high-performance maritime structures.