Contents

O1 Tool Steel vs 1095 High Carbon Steel: Properties and Uses Guide

- John

O1 steel contains alloying elements like chromium and molybdenum, which increase wear resistance, dimensional stability, and corrosion resistance. 1095 steel lacks these alloying elements, making it simpler and more cost-effective but more prone to corrosion.

If you’re trying to decide which material to choose, SteelPro Group has the answer: O1 steel is ideal for precision tools and repeated use, while 1095 steel is best for knives and cutting tools that demand a very sharp edge.

Overview of O1 Tool Steel vs 1095 High Carbon Steel

O1 tool steel is a high-carbon, oil-hardened alloy. It is recognized for its excellent abrasion resistance, durability, and dimensional consistency during heat treatment. It is commonly used for making precision tools, dies, and other applications that require high hardness and the ability to retain a sharp edge.

1095 steel is a type of carbon-rich steel containing around 0.95% carbon. It offers high hardness, excellent edge retention, and good wear resistance. It is frequently utilized for knives, blades, and other cutting instruments. 1095 is susceptible to rust and demands consistent upkeep.

Chemical Composition of O1 and 1095 Steel

| Element | O1 Tool Steel | 1095 High Carbon Steel |

| Carbon (C) | 0.90 – 1.00% | 0.90 – 1.03% |

| Manganese (Mn) | 0.30 – 0.50% | 0.30 – 0.50% |

| Chromium (Cr) | 0.40 – 0.60% | – |

| Molybdenum (Mo) | 0.15 – 0.30% | – |

| Silicon (Si) | 0.10 – 0.35% | 0.10 – 0.30% |

| Phosphorus (P) | ≤ 0.030% | ≤ 0.040% |

| Sulfur (S) | ≤ 0.030% | ≤ 0.050% |

- Alloying Elements

O1 contains chromium, manganese, and molybdenum, which are absent in 1095 steel.

Chromium increases corrosion resistance and contributes to wear resistance by forming harder carbide phases. Molybdenum enhances hardness at high temperatures and improves dimensional stability during heat treatment, making O1 more suitable for precision tools.

In contrast, 1095’s lack of these alloying elements limits its wear resistance and ability to maintain sharpness under demanding conditions.

- Silicon (Si)

Both steels contain silicon, which acts as a deoxidizer during production. The slight difference in silicon content doesn’t drastically affect performance, but higher silicon in O1 could provide marginally better hardness retention and strength at elevated temperatures.

- Phosphorus (P) and Sulfur (S)

Both steels have low levels of phosphorus and sulfur, minimizing brittleness and ensuring better machinability. O1 has slightly lower phosphorus content, offering marginally better toughness compared to 1095.

Mechanical Properties of O1 and 1095 Steel

| Property | O1 Tool Steel | 1095 High Carbon Steel |

| Hardness (HRC) | 58-64 HRC | 55-65 HRC |

| Tensile Strength | 1,200-1,400 MPa | 1,100-1,300 MPa |

| Yield Strength | 800-1,100 MPa | 600-1,000 MPa |

| Elongation | 10-15% | 10-12% |

| Impact Toughness | Moderate | Low |

| Modulus of Elasticity | 210 GPa | 210 GPa |

| Poisson’s Ratio | 0.28 | 0.29 |

O1 and 1095 Steel Performance Comparison

Wear Resistance

O1 steel, with its chromium and molybdenum content, offers higher wear resistance, making it better suited for applications involving repeated use and friction.

1095 steel, lacking alloying elements, wears faster under heavy use.

Edge Retention

1095 steel, with its higher carbon content and simpler structure, provides superior edge retention, making it ideal for sharp cutting tools like knives and blades.

O1 steel also holds a sharp edge well but prioritizes durability over edge retention.

Corrosion Resistance

O1 steel exhibits superior resistance to corrosion thanks to its chromium content, which creates a protective oxide coating.

1095 steel, lacking significant alloying elements, is more susceptible to rust and needs frequent upkeep to avoid deterioration.

Toughness

O1 steel has higher toughness, making it less likely to crack or chip under impact or stress.

1095 steel, while hard, is more brittle and prone to chipping when subjected to sudden forces.

Heat Treatment Stability

O1 steel provides better dimensional stability during heat treatment, allowing for precise tool manufacturing with minimal distortion.

1095 steel requires careful handling during heat treatment to avoid warping and cracking.

Ease of Sharpening

1095 steel is easier to sharpen with standard tools, making it a preferred choice for applications requiring frequent resharpening.

O1 steel, while harder to sharpen, retains its edge longer under heavy use.

Cost

1095 steel is more cost-effective than O1 due to its simpler composition and lack of alloying elements. It is often chosen for mass-produced items like knives.

O1 steel, while more expensive due to alloying elements, provides better performance in precision tools. It is more economical for applications where durability and accuracy are critical.

Different Applications of O1 and 1095 Steel

O1 Tool Steel Applications

- Dies and Punches: Stamping dies, blanking punches.

- Blades: Industrial shearing blades, woodworking plane blades.

- Gauges: Inspection gauges, go/no-go gauges.

- Jigs and Fixtures: Positioning jigs, assembly fixtures.

- Shims: Precision shims for machinery.

1095 High Carbon Steel Applications

- Knives: Hunting knives, kitchen knives, tactical knives.

- Blades: Razor blades, utility blades, saw blades.

- Axes and Hatchets: Outdoor axes, camping hatchets.

- Chisels: Woodworking chisels, metalworking chisels.

- Springs: Small mechanical springs, lock springs.

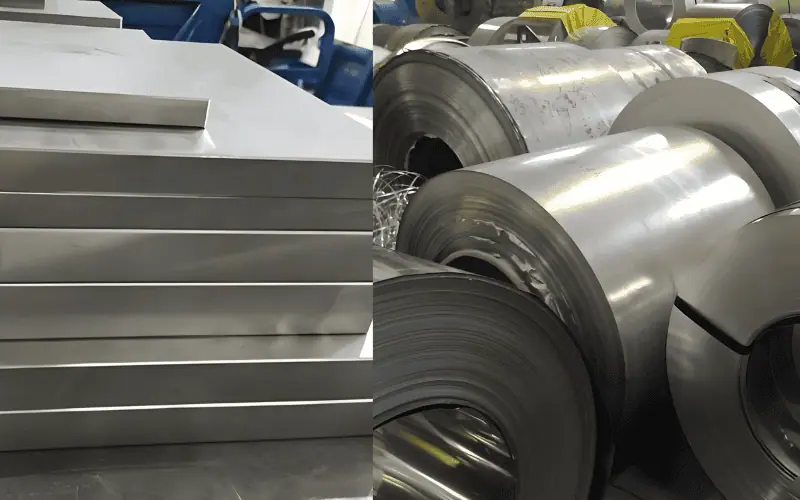

Your Trusted Supplier for O1 and 1095 Steel

SteelPro Group provides high-quality O1 and 1095 steels. Beyond this, we also offer tailored services designed to add value to your project. Whether it’s custom machining, precision cutting, or heat treatment consultation, we ensure that every step of your production process is optimized for efficiency and performance.