Contents

Overview of Steel Bars: Type, Manufacturing, Properties, and Uses

- John

Steel bars are essential in many industries because of their strength, versatility, and durability. This guide will introduce steel bars from the perspectives of properties, types, and applications, providing a comprehensive understanding of this essential material.

What is Bar Stock?

Bar stock, also called blank, slug, or billet, is raw purified metal used to make parts and products. It’s shaped by forging, extrusion, or machining into forms like round, square, or hexagonal. Steel bar is a common type of bar stock used for further fabrication or construction. Bar stock serves as the starting material for various custom metal components in different industries.

What are Steel Bars?

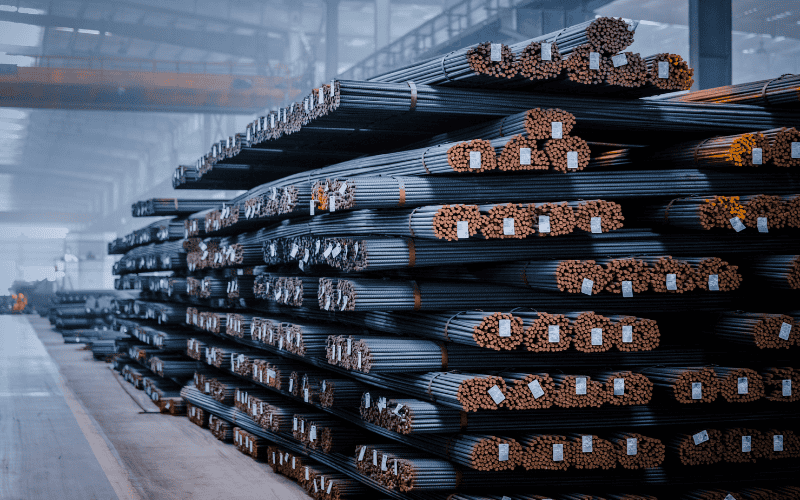

Steel bars, including rebar, are solid rods composed mainly of iron with a small percentage of carbon and other elements to enhance strength and ductility. Produced primarily through hot rolling, these bars offer high tensile strength and are ideal for reinforcing concrete and masonry structures. They come in various shapes, such as round, square, flat, and hexagonal, and are widely used in construction, automotive, and heavy machinery industries for their strength and versatility.

Types of Steel Bars

Steel bars can be categorized by their production process, shape, and surface characteristics. Each type is tailored for specific applications and provides distinct properties.

By Production Process

Hot Rolled Steel Bars

Steel billets are heated to elevated temperatures and then processed through rolling mills to form them into bars. This process improves ductility and malleability. This process improves ductility and malleability. Our hot rolled steel bars can be made into various products, including rebar, plain round bars, and stainless steel hot rolled bars.

Cold Rolled Steel Bars

Involves rolling steel bars at ambient temperature to enhance their strength and surface finish. Cold-rolled bars are commonly utilized in precision applications that demand a smooth surface and strict tolerances. They are commonly used to produce high-precision components like threaded bars and tool steel.

Cold Drawn Steel Bars

Steel bars are drawn through dies to decrease their diameter and extend their length, improving strength and accuracy. This process produces bars with high dimensional accuracy and improved mechanical properties. Cold-drawn bars are often used to make products like wire rods, precision shafts, and other components requiring tight tolerances.

Cold Twisted Steel Bars

Deformed bars are twisted at room temperature to improve tensile strength and bonding properties with concrete. This process is commonly used to produce high-strength rebar for reinforced concrete structures, such as twisted rebars, which are ideal for high-stress applications in construction.

Cold Twisted Deformed Bars (CTD Bars)

CTD bars are produced by twisting deformed steel at room temperature, enhancing their tensile strength and bonding with concrete. However, the cold twisting process can introduce internal stresses, leading to brittleness and reduced ductility.

Features:

- Improved tensile strength

- Good bonding with the concrete

- Prone to brittleness

- Reduced ductility

Applications: Used in reinforced concrete structures, particularly in low-cost housing.

Cost: Lower due to simpler manufacturing but less durable than newer technologies.

HYSD Bars

High Yield Strength Deformed (HYSD) bars are designed for better strength and flexibility, replacing cold twisted bars in many applications.

Features:

- High yield strength

- Superior flexibility

- Prone to corrosion in humid environments

Applications: Used in high-stress applications, including bridges, dams, and multi-story buildings.

Cost: Moderate, offering a good balance between strength and cost.

Heat-Treated Steel Bars

Processes such as quenching and tempering are used to improve the mechanical properties of steel bars. Heat-treated bars exhibit enhanced hardness, strength, and toughness, rendering them ideal for challenging applications.

Thermo-Mechanically Treated (TMT) Bars

TMT steel bars for construction are produced through a controlled thermo-mechanical process that enhances both strength and flexibility. These bars are favored in construction projects due to their superior mechanical properties, making them ideal for reinforcing concrete structures.

Features:

- High tensile strength

- Good bendability

- Corrosion resistance

- Earthquake resistance

Applications: Widely used in construction, bridges, and infrastructure projects.

Cost: Moderate, balancing strength and flexibility.

Quenched and Tempered (QT) Rebars

QT rebars are heat-treated through quenching and tempering to improve hardness and strength, making them suitable for heavy-duty applications.

Features:

- High hardness

- Excellent fatigue resistance

- High strength-to-weight ratio

Applications: Used in heavy construction, industrial structures, and machinery.

Cost: Higher due to intensive processing and enhanced properties.

TMX Rebars

TMX rebars are advanced, high-strength bars made using German Thermex technology. They offer superior tensile strength and flexibility, making them suitable for critical infrastructure projects.

Features:

- High thermal stability

- Excellent weldability

- Resistance to corrosion

- Superior elongation properties

Applications: Ideal for high-rise buildings, bridges, and earthquake-prone areas.

Cost: Generally higher than TMT due to advanced manufacturing technology and enhanced mechanical properties.

By Bar Shapes

Steel bars can be distinguished by their shapes, each designed for specific applications:

Round Bars

With a smooth and circular cross-section, they are commonly used in construction and manufacturing. They are also common in machining and forging applications due to their ease of use.

Rebar

Rebar typically comes in two types: plain rebar and deformed rebar. It features ribs or ridges along its length to improve bonding with concrete. It’s used to reinforce concrete structures improving its overall durability and load-bearing capacity. Essential in construction projects like foundations, beams, and slabs.

Twisted Bars (CTD)

Typically made from scrap iron, these bars undergo a twisting process at room temperature. This method can introduce residual stresses and potential defects. But they still offer improved tensile strength and bonding properties with concrete. Commonly used in the construction industry, they reinforce beams, columns, and foundations in high-stress applications.

Flat Bars

Rectangular cross-section, used in framing, braces, and supports. Flat bars are frequently employed in fabrication projects, offering ease of welding and cutting.

Square Bars

Square cross-section, often used in manufacturing and repair work. Their consistent shape and strength make them perfect for precision and stability applications.

Hexagonal Bars

Hexagonal cross-section, is used for making fasteners and custom machinery parts. Their unique shape offers more grip, essential for mechanical and engineering uses.

By Surface Characteristics

Plain Bars

Possess a smooth surface, they are generally used in applications where strong bonding with concrete is not necessary.

Ribbed Bars

Feature transverse ribs on the surface to enhance the bonding with concrete, commonly used in reinforced concrete structures.

Threaded Bars

Have threads along their length, allowing them to be easily connected with other components, often used in mechanical applications and construction.

Epoxy-Coated Bars

Coated with epoxy to prevent corrosion, ideal for use in environments where the steel is exposed to moisture or chemicals.

Galvanized Bars

Covered with a layer of zinc to prevent corrosion, are used in outdoor and marine environments where rust resistance is crucial.

-SteelPRO Group offers a variety of customizable Steel Bars, visit our Steel Bar page now!-

What are Steel Bars Made of?

The manufacturing process of steel bars involves several critical steps, starting from the extraction of iron ore to the final cooling and finishing of the steel bars. Here is a detailed overview of the process:

1. Smelting

During the smelting process, iron ore is transported to steel manufacturing facilities and combined with coke and limestone in a blast furnace. The extreme heat melts the iron ore, separating it from its impurities. This produces molten iron, commonly referred to as hot metal or pig iron.

2. Refining

The molten iron is moved to a basic oxygen furnace or an electric arc furnace for further refinement. During this process, oxygen is introduced into the molten iron to reduce the carbon content, converting it into steel. Additional alloying elements may be incorporated to attain the desired chemical composition.

3. Casting

The processed steel is then cast into molds to create semi-finished forms known as billets, blooms, or slabs. These semi-finished products are solidified and prepared for further processing.

4. Hot Rolling

The billets are reheated and fed through rolling mills, where they are formed into elongated bars. This procedure includes several stages of rolling to reach the specified cross-sectional dimensions. Hot rolling improves the ductility and malleability of the steel.

5. Cold Processing (If Applicable)

Depending on the final application, the hot rolled bars may undergo additional cold processing steps such as:

- Cold Rolling: To enhance strength and surface finish.

- Cold Drawing: To enhance dimensional accuracy and mechanical properties.

- Cold Twisting: To increase tensile strength and bonding properties with concrete.

6. Heat Treatment (If Applicable)

Some steel bars undergo thermal processing methods such as quenching and tempering to enhance their mechanical characteristics. Surface treatments such as galvanization or epoxy coating can be applied to enhance the corrosion resistance of the steel bars.

7. Surface Treatment (If Applicable)

Surface treatments like galvanization or epoxy coating may be applied to enhance the corrosion resistance of the steel bars.

8. Cutting and Shaping

The steel bars are trimmed to the specified lengths and shapes using automated cutting equipment. This step ensures that the bars achieve the precise dimensions required for their intended applications.

9. Cooling and Finishing

Finally, the steel bars are cooled and undergo finishing processes such as straightening, inspection, and quality control.

By following these steps, the raw iron ore is transformed into high-quality steel bars ready for various construction and industrial applications.

Properties of Steel Bars

Steel bars have essential mechanical and physical properties that provide the necessary strength, durability, and versatility for various applications.

Mechanical Properties

- Tensile Strength: Steel bars have high tensile strength, making them ideal for reinforcing concrete and masonry structures, preventing them from collapsing under tension.

- Ductility: The capacity to deform under stress without breaking, which is crucial for absorbing energy during events like earthquakes.

- Flexibility: Can be bent or shaped without losing strength, useful in complex architectural designs and structural elements.

- Weight-to-Strength Ratio: Provides high strength with relatively low weight, making them efficient for structural use without adding excessive load.

- Weldability: Some steel bar grades can be readily welded, enabling versatile fabrication and construction uses.

Physical Properties

- Durability: Resistant to abrasion, corrosion, and weather conditions, guaranteeing a long service life even in severe environments.

- Thermal Conductivity: Steel bars efficiently conduct heat, which is essential in applications requiring heat dissipation or thermal resistance.

- Magnetic Properties: Steel bars are generally magnetic, making them suitable for applications where magnetic response is required, such as in certain sensors and electric motors.

- Electrical Conductivity: Steel bars have moderate electrical conductivity, which is useful in grounding applications and in structures where electrical current needs to be conducted safely.

- Expansion Coefficient: Steel bars have a known coefficient of thermal expansion, which ensures predictable behavior under temperature variations, crucial for maintaining structural integrity in varying climates.

These mechanical and physical characteristics render steel bars a flexible and essential material in construction and numerous other industries.

What are the Common Grades of Steel Bars? (USA)

Steel bar grades are typically denoted by a combination of the American Society for Testing and Materials (ASTM) designation, the standard number, and the minimum yield strength. For example, let’s look at three common grades used in the USA:

Hot Rolled Steel Bars Grades

| Grade | Description | Applications |

| ASTM A615 Grade 40 | Commonly used in general construction with good weldability and moderate strength. | General construction. |

| ASTM A615 Grade 60 | Most frequently used in construction, offering high strength and good weldability. | Construction. |

| ASTM A706 Grade 60 | Provides ductility and weldability, ideal for seismic reinforcement. | Seismic reinforcement. |

Cold Rolled Steel Bars Grades

| Grade | Description | Applications |

| ASTM A108 Grade 1018 | Frequently employed in manufacturing and machining due to its superior mechanical properties and ease of processing. | Manufacturing, machining |

| ASTM A108 Grade 1045 | Offers higher strength and hardness, suitable for heavy-duty applications and precision machining. | Heavy-duty applications, precision machining |

Stainless Steel Rebar Grades

| Grade | Description | Applications |

| ASTM A955 Grade 316 | Provides excellent corrosion resistance, utilized in harsh environments like marine structures and chemical plants. | Marine structures, chemical plants |

| ASTM A955 Grade 304 | Offers good corrosion resistance and strength, used in construction where aesthetic appearance and durability are important. | Construction, aesthetic and durable applications |

Less Common High-Grade Steel Bars Grades

| Grade | Description | Applications |

| ASTM A1035 Grade 100 | Known for its ultra-high strength, used in critical infrastructure projects such as bridges and high-rise buildings where maximum strength is essential. | Bridges, high-rise buildings |

| ASTM A706 Grade 80 | Provides a combination of high strength and ductility, used in applications that require superior seismic performance and reduced rebar congestion. | Seismic reinforcement, applications requiring reduced rebar congestion |

| ASTM A955 Grade 904L | An austenitic stainless steel grade with exceptional resistance to corrosion and pitting, used in extreme environments such as seawater desalination plants and high-acid processing industries. | Seawater desalination plants, high-acid processing industries |

Understanding the common and high-grade steel bar options helps in selecting the appropriate type for your specific project requirements, ensuring optimal performance and longevity.

What is the Best Grade of Steel Bars?

The best steel bar grade depends on your project’s needs. Common choices include ASTM A615 Grade 40-75 for general construction and ASTM A706 Grade 60-75 for improved weldability. For higher toughness and wear resistance, 4140 alloy steel bars is ideal, especially for heavy-duty components.

Applications of Steel Bars

Steel bars are crucial across multiple sectors due to their robustness, longevity, and versatility. They are key to reinforcing structures and providing long-term stability and safety.

In Different Industries

- Construction: Used in building foundations, columns, beams, and slabs to reinforce concrete structures.

- Infrastructure: Crucial for bridges, tunnels, highways, and dams to ensure structural integrity and durability.

- Manufacturing: Utilized in producing machinery components, tools, and equipment because of their strength and longevity.

- Automotive: Vital for the production of vehicle frames, suspension systems, and other essential parts.

- Energy: Used in the construction of power plants, oil rigs, and renewable energy installations due to their resilience.

- Shipbuilding: Critical for fabricating ship hulls, decks, and other structural elements to guarantee safety and functionality.

Specific Components

- Foundations: Provide tensile strength to resist ground movement and weight of the structure.

- Columns and Beams: Reinforce vertical and horizontal elements, ensuring stability and support.

- Slabs: Employed in floor and roof slabs to avoid cracking and structural collapse.

- Bridges: Reinforce spans to handle dynamic loads and environmental stress.

- Tunnels: Provide support to withstand earth pressure and ensure safe passage.

- Retaining Walls: Support soil laterally, enhancing stability and preventing soil pressure failure.

How to Buy Steel Bars for Your Project

Choosing the right steel bars involves assessing quality, specifications, and suppliers. Proper maintenance ensures their longevity and performance in construction projects.

Quality and Specification

When purchasing steel bars, consider the following:

- Grade and Specification: Verify that the steel bars comply with the necessary standards for your particular application.

- Quality Inspection: Check for certifications and quality control processes. Our products are subjected to thorough testing prior to shipment, including both non-destructive and destructive tests. Additionally, we can customize a specific testing plan tailored to your needs.

- Supplier Reputation: Choose a well-regarded supplier with a history of delivering high-quality products.

How to Calculate Pounds of Reinforcing Steel Purchased

Use this formula to calculate the actual weight of steel bars on-site: Actual Weight=Total Weight with Steel Bars−Empty Truck Weight

For an easy calculation, visit our online calculator.

What is the Formula for Calculating Steel Bars’ Weight?

The formula for calculating the weight of steel bars is: Weight (kg)=Length (m)×Cross-sectional Area (m2)×Density (kg/m3).

Payment

Keep all receipts, product information, and warranty certificates. We provide multiple quality inspection certificates and offer a lifetime warranty for our products.

Maintenance and Longevity of Steel Bars

Proper maintenance of steel bars is crucial to ensure their longevity and performance in construction projects. Here are some key practices to consider:

- Corrosion Protection: One of the main threats to the longevity of steel bars is corrosion. To protect against this, ensuring proper concrete cover and maintaining the pH level of concrete can prevent corrosion.

- Regular Inspections: Conduct regular inspections of steel bars in structures to detect any signs of wear, corrosion, or damage.

- Environmental Control: Store steel bars in a dry, covered area to protect against moisture and other corrosive elements.

- Repair Techniques: If steel bars show signs of damage or corrosion, appropriate repair techniques should be employed. This can include applying rust inhibitors, repairing concrete cover, or replacing severely damaged bars.

- Proper Installation: Ensure steel bars are installed correctly, following all engineering specifications and standards. Improper installation can result in premature wear and significant structural problems.

By following these maintenance practices, the durability and lifespan of steel bars in construction projects can be significantly enhanced, ensuring the long-term integrity and safety of the structures they reinforce.

How Do You Read Steel Bar Sizes?

Steel bar sizes are typically indicated by a number that corresponds to the bar’s diameter in millimeters. For example, a #4 bar is 12 mm in diameter.

Find the Best Steel Bars Supplier for Your Project!

This guide provides a comprehensive overview of steel bars, from their types and manufacturing processes to their properties and applications. Make informed decisions to guarantee the success of your construction projects by using high-quality steel bars.

Steel bars are crucial for guaranteeing the strength and longevity of your construction projects. When you receive your order, store the steel bars in a warehouse to protect them from the elements and maintain their quality.

SteelPRO Group offers a wide range of steel bars, including stainless steel bars, tool steel bars, and structural steel bars. Our stainless options feature the 347/347H steel bar for high-temperature durability. Visit our blog or contact us for quotes!