Contents

D3 Tool Steel | Cold-Work Steel: Properties, Equivalent Grades, Applications, Shapes

- John

D3 steel is a top choice in the cold work tool steel group, recognized for its outstanding hardness, durability, and ability to maintain a sharp edge. With 2.0-2.4% carbon and 12.0-13.0% chromium, it’s ideal for tools like dies and punches, easily handling high stress and friction. D3 is oil-quenched for hardening, but it cannot undergo secondary hardening. Its microstructure contains large amounts of chromium-rich carbides, which contribute to its outstanding wear resistance and durability in demanding applications.

This article covers the key properties, heat treatment, equivalent grades, specifications, shapes, and applications of D3 steel, helping you make an informed choice for your most demanding tool requirements.

Properties of D3 Cold Work Tool Steel

D3 steel offers excellent hardness, wear resistance, and stability, making it ideal for demanding tool applications. Here’s a brief overview of its main features to give you a better idea of how it performs in practical applications.

Chemical Composition of D3 Steel

Here is the chemical composition table for D3 steel:

| Element | Content (%) |

| Carbon, C | 2.0 – 2.4 |

| Chromium, Cr | 12.0 – 13.0 |

| Manganese, Mn | 0.30 – 0.60 |

| Silicon, Si | 0.30 – 0.50 |

| Vanadium, V | 0.10 – 0.30 |

| Phosphorus, P | ≤ 0.03 |

| Sulfur, S | ≤ 0.03 |

Mechanical Properties of D3 Steel

Here is the table for the mechanical properties of D3 steel:

| Property | Metric Units | Imperial Units |

| Poisson’s Ratio | 0.28 | 0.28 |

| Elastic Modulus | 210 GPa | 30.5 × 10⁶ psi |

| Tensile Strength | 1,550 – 1,750 MPa | 225 – 254 ksi |

| Yield Strength | 1,400 – 1,600 MPa | 203 – 232 ksi |

| Impact Toughness | 8 – 12 J/cm² | 0.15 – 0.22 ft-lb/in² |

| Elongation | 6 – 10% | 6 – 10% |

D3 steel’s high tensile strength (1,550 – 1,750 MPa) makes it perfect for tools that endure heavy stress and impact without deforming.

Physical Properties of D3 Steel

| Property | Metric Units | Imperial Units |

| Density | 7.7 g/cm³ | 0.278 lb/in³ |

| Melting Point | 1,200 – 1,250 °C | 2,192 – 2,282 °F |

| Specific Heat Capacity | 460 J/kg·K | 0.110 Btu/lb·°F |

| Thermal Conductivity | 25 W/m·K | 14.5 BTU·in/h·ft²·°F |

| Coefficient of Thermal Expansion | 11.5 µm/m·K | 6.39 × 10⁻⁶ in/in·°F |

With a melting point between 1,200 – 1,250°C, D3 steel withstands high temperatures, making it perfect for demanding tool applications. If thermal stability is your priority, D2 or A2 steel may offer better heat resistance for prolonged exposure to elevated temperatures.

What Is the Hardness of D3 Steel?

D3 steel usually reaches a hardness of 58-62 HRC after correct heat processing, providing outstanding ability to maintain a sharp edge.

What Is D3 Super Strength?

D3 steel’s super strength comes from its high carbon and chromium content, providing high wear resistance, toughness, and dimensional stability in demanding tool applications.

Heat Treatment of D3 Cold Work Steel

For D3 steel, heat treatment is the key to achieving the right hardness, toughness, and wear resistance balance. Following the correct annealing, tempering, and hardening steps helps avoid cracks and distortion while ensuring the steel performs well in high-stress, high-friction applications.

Annealing

Annealing D3 steel helps relieve internal stresses, making it easier to machine and process. For this, heat the steel to 871°C (1,600°F) in a controlled atmosphere furnace, and keep it at that temperature for 1 to 2 hours. Once finished, cool it gradually at a rate no faster than -6°C (20°F) per hour until the furnace turns black, then allow the material to cool in the air.

Tips:

- Use a controlled atmosphere furnace to avoid oxidation, which can degrade material properties.

- Slow cooling is crucial—don’t rush the process to prevent distortion. Avoid cooling too fast, as this could cause internal stresses or cracks.

- Post-annealing inspection: After cooling, visually inspect the material for any signs of cracks or defects, especially if there was rapid cooling. Any issues here may require redoing the process or adjusting cooling rates.

Tempering

Once D3 steel has cooled to room temperature after hardening, tempering is the next step. This process reduces brittleness and fine-tunes the hardness for the best balance between strength and toughness. Heat the steel in the tempering furnace and raise the temperature slowly to the desired range (usually 200-300°C or 390-570°F). For best results, temper for about 1 hour per inch of thickness.

Tips:

- Multiple tempering cycles may be needed to achieve the optimal hardness and toughness balance, especially for thick or large parts.

- Slow heating helps avoid thermal stress and ensures the steel is evenly processed.

- Allow air cooling after tempering to avoid cracks or uneven hardness. Cooling in oil or water can introduce thermal stress.

- Check hardness after tempering: Use a hardness tester to ensure the steel has reached the desired hardness after tempering.

Hardening

Tempering D3 steel is what gives it its great toughness and resistance to wear. To do this properly, heat the steel to 954°C (1,750°F) and soak it for 20-25 minutes, adding 5 minutes for every inch of thickness. After soaking, cool the steel in oil to reach the required hardness. D3 steel is very sensitive to overheating, so it’s important to avoid that to get the best results.

Tips:

- Ensure even heating across the entire steel section to prevent warping or uneven hardening. Heating a part too quickly or unevenly can create internal stresses.

- Avoid overheating—temperatures above 1,050°C (1,922°F) can cause grain growth, which reduces hardness.

- Monitor oil temperature carefully—oil that’s too cold can lead to cracking, while oil that’s too hot can cause a softer surface.

- Post-quenching checks: After quenching, check for distortion. If you notice any, make sure the steel was heated evenly, and the quenching oil was at the right temperature.

By following these detailed steps and considering these additional tips, you’ll get the most out of D3 steel, ensuring it performs well in demanding cold work applications.

Equivalent Grades of D3 Steel

The following table lists the approximate equivalent grades of D3 steel according to various international standards. These are approximate equivalents, and slight differences in material properties may exist.

| Standard | AISI/SAE | DIN (Germany) | JIS (Japan) | BS (UK) | AFNOR (France) | ISO |

| Grade | D3 | 1.208 | SKD1 | X153CrMoV12 | Z120CD12 | 1.208 |

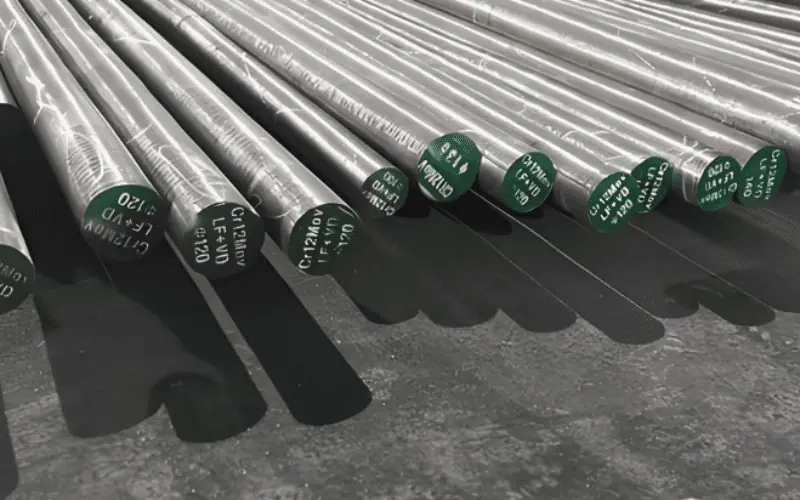

Applicable Specifications and Shapes We Provide

We provide D3 steel in compliance with ASTM A681 and other recognized standards, ensuring consistent quality for cold work tooling applications. D3 steel, known for its high carbon and chromium content, is ideal for manufacturing precision tools that require exceptional hardness, wear resistance, and dimensional stability.

Specifications:

- AISI/SAE: D3

- ASTM Standard: ASTM A681

Shapes We Provide:

We provide a variety of shapes and dimensions to suit our customers’ unique requirements, such as:

- D3 Steel Sheets – Perfect for die cutting, stamping, and forming applications.

- D3 Steel Plates – Suitable for larger tool and die manufacturing, ensuring strength and durability.

- D3 Steel Bars – Available in various diameters and lengths for machining into custom parts.

- D3 Steel Blanks – Semi-finished products ideal for further machining into tools.

- D3 Steel Forgings – Custom-forged shapes designed for complex or large tools that require additional strength.

- D3 Steel Cold Finished Bars – Precisely machined bars for strict tolerances and excellent dimensional precision.

Each of these shapes is processed to meet the exacting standards required for cold work tooling applications, ensuring the highest performance in demanding industries like automotive, aerospace, and heavy machinery.

What Is the Difference Between D2 and D3 Steel?

D2 steel has higher wear resistance and is better suited for high-wear applications, while D3 offers better toughness and is more resistant to cracking.

Applications of D3 Cold Work Tool Steel

D3 cold work tool steel is highly valued for its excellent wear resistance, hardness, and dimensional stability, making it the preferred choice for a wide range of demanding applications.

1. Die Casting and Stamping Tools

Die Blanks, Stamping Dies, Blanking Dies, Piercing Dies, Forming Dies

2. Cold Forming Tools

Punches, Dies for Cold Heading, Blanking, Piercing, Extrusion Dies, Forming Rolls

3. Shearing and Cutting Tools

Shear Blades, Slitter Knives, Trim Dies, Cutoff Dies, Knives for Slitting

4. Plastic Molds and Dies

Injection Molds, Compression Molds, Plastic Molding Dies, Nozzles and Screw Tips

5. Aerospace and Automotive Industry Tools

Automotive Tooling, Aerospace Dies, Stamping Dies, Punch Press Tools

6. Other Specialized Applications

Knives and Blades for Woodworking, Wear Inserts for Mining, Powder Compaction Dies, Compaction Pins, Pelletizer Blades

D3 Cold Work Tool Steel Manufacturer

D3 cold work tool steel is a high-carbon, high-chromium material, known for its exceptional hardness, wear resistance, and durability, primarily used for dies, punches, and other cold work tooling applications.

At SteelPRO Group, we provide D3 Cold Work Tool Steel with unique heat treatment processes and high-quality surface treatments tailored to your needs. Our D3 tool steel is available not only in annealed condition but also in hardened and tempered states. If you require specific conditions, feel free to contact us for customized solutions that will meet your toughest tooling demands.