Contents

Cold Work Tool Tool Steel: Properties, Products, Uses

- John

Cold work tool steels offer the perfect balance of durability and wear resistance for short-term, high-stress applications. SteelPro Group is here to provide the best cold work tool steels, ensuring you get the ideal grade for your needs—whether it’s oil-hardening, air-hardening, or high-carbon chromium steel.

What Is Cold Work Tool Steel?

Cold work tool steel is high-carbon steel used in tooling applications below 316°C (600°F). t can be categorized into O-series (oil-hardening), A-series (air-hardening), and D-series (high-carbon chromium). Its hardness typically ranges from 55 to 65 HRC, providing wear resistance for short-term applications like cutting and forming molds. Compared to high-speed steel, it offers higher wear resistance but lower toughness.

What Are The Properties of Cold Work Tool Steel?

Composition: High-carbon steel with low alloying elements like tungsten, manganese, chromium, and molybdenum to improve hardenability and wear resistance.

Hardness: Typically ranges from 55 to 65 HRC, offering a balance between wear resistance and toughness depending on grade and heat treatment.

Wear Resistance: Excellent wear resistance due to high carbon content, making it ideal for high-wear tooling applications.

Hardenability: Good hardenability with oil quenching capability, minimizing distortion compared to W-series steels.

Toughness: Lower toughness than high-speed steels, more prone to cracking under impact or shock loading.

Cost: Relatively inexpensive, offering cost-effectiveness for short-term tooling needs due to its high carbon content and lower alloying elements.

Overview of Cold Work Tool Steel Types And Grades

Cold work tool steel can be classified into three main categories: O-series, A-series, and D-series, each with distinct characteristics and applications.

O-series (Oil-hardening) steels are cost-effective and provide good wear resistance with minimal distortion during oil quenching. They are ideal for applications requiring good machinability and moderate hardness, such as cutting tools, forming dies, and gauges.

A-series (Air-hardening) steels offer excellent dimensional stability and require no quenching medium, as they harden in air. They are commonly used for tools requiring high wear resistance and good toughness, including punches, dies, and stamping tools.

D-series (High-carbon chromium) steels contain higher carbon and chromium content, providing superior wear resistance and hardness, making them ideal for high-stress applications like die-casting molds, shear blades, and heavy-duty stamping tools.

Chemical Composition of Cold Work Tool Steel Grades

| Steel Grade | C | Mn | Si | Cr | W | Mo | V | Ni |

| O1 | 0.94 | 1.20 | 0.30 | 0.50 | 0.50 | |||

| O6 | 1.45 | 1.00 | 0.90 | 0.25 | ||||

| L6 | 0.70 | 0.60 | 0.25 | 0.70 | 1.40 | |||

| A2 | 1.00 | 0.75 | 0.30 | 5.00 | 1.00 | 0.25 | ||

| A8 | 0.55 | 0.30 | 0.95 | 5.00 | 1.25 | 1.25 | ||

| A9 | 0.55 | 0.35 | 1.05 | 5.15 | 1.55 | 1.00 | 1.50 | |

| A10 | 1.35 | 1.80 | 1.20 | 0.20 | 1.50 | 1.85 | ||

| D2 | 1.50 | 0.30 | 0.30 | 12.00 | 0.75 | 0.90 | ||

| D3 | 2.15 | 0.40 | 0.40 | 12.25 | 0.25 | |||

| D7 | 2.30 | 0.40 | 0.40 | 12.50 | 1.10 | 4.00 | ||

| S1 | 0.53 | 0.25 | 0.25 | 1.35 | 2.00 | 0.25 | ||

| S7 | 0.50 | 0.75 | 0.25 | 3.25 | 1.40 | |||

| H13 | 0.40 | 0.40 | 1.00 | 5.25 | 1.35 | 1.00 | ||

| M2 | 0.40 | 0.28 | 0.30 | 4.15 | 6.15 | 5.00 | 1.85 | |

| CPM 1V | 0.55 | 0.40 | 0.50 | 4.00 | 4.25 | 1.00 | 0.50 | |

| CPM 3V | 0.85 | 0.30 | 1.00 | 5.00 | 1.35 | 2.75 | ||

| CPM M4 | 1.45 | 0.25 | 0.25 | 4.50 | 5.50 | 5.20 | 3.85 | |

| CPM 9V | 1.80 | 0.50 | 0.90 | 5.25 | 1.35 | 9.00 | ||

| CPM 10V/A11 | 2.45 | 0.50 | 0.90 | 5.25 | 1.35 | 9.80 |

Perfomance Comparison of Cold Work Tool Steel Grades

| Grades | Machinability | HRC |

| О6 | 90 | 60 |

| L6 | 125 | 60 |

| A2 | 75 | 57 |

| A8 | 70 | 60 |

| A9 | 80 | 56 |

| A10 | 70 | 60 |

| D2 | 90 | 62 |

| D3 | 55 | 63 |

| D7 | 35 | 63 |

| S1 | 75 | 57 |

| S7 | 75 | 57 |

| H13 | 70 | 48 |

| H13S | 40 | 44 |

| M2 | 55 | 64 |

| CPM 1V | 70 | 57 |

| CPM 3V | 55 | 62 |

| CPM M4 | 45 | 63 |

| CPM 9V | 40 | 53 |

| CPM 10V/A11 | 40 | 63 |

What Is Cold Work Tool Steel Used For?

Cold work tool steel is used for:

- Cutting tools (e.g., knives, shears)

- Punches and dies (for stamping and punching)

- Forming tools (e.g., bending, shaping dies)

- Molds for plastic and rubber

- Gauges and measuring tools

- Chucks and fixtures

- Blades for shearing, trimming, and slitting

- Dies for cold-heading and drawing operations

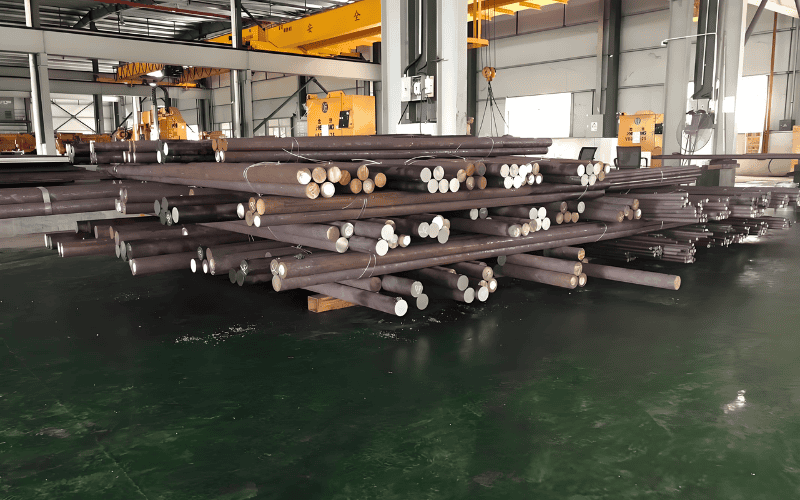

Cold Work Tool Steel Solutions

At SteelPro Group, we offer a wide range of cold work tool steels, tailored to meet the demands of your specific tooling applications. Contact us to discuss your requirements and receive expert advice on selecting the perfect material for your needs. Let us help you optimize performance and reduce downtime with our premium steel solutions.