Contents

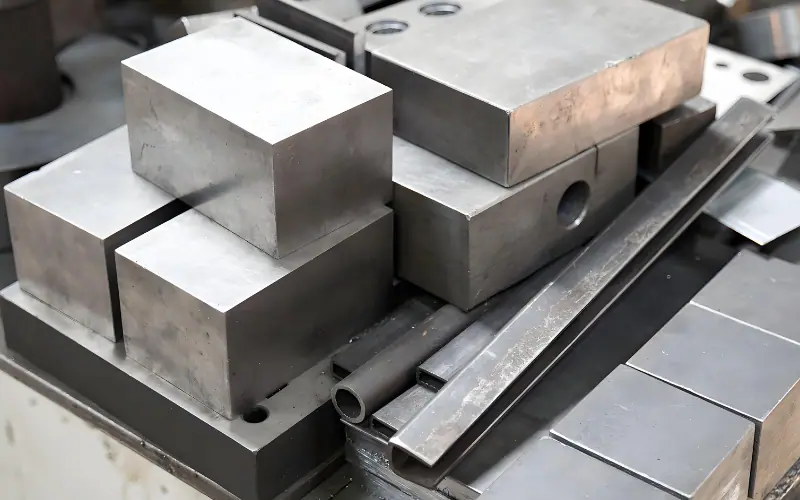

Hot Work Tool Steel Overview

- John

At SteelPro Group, we provide premium-grade hot work tool steels, designed to extend tool life, reduce downtime, and improve operational efficiency. Discover how choosing the right material can optimize your production and deliver long-term cost savings.

What Is Hot Work Tool Steel?

Hot work tool steel is a type of advanced steel designed for use in high-temperature environments, mainly in operations such as die casting, extrusion, and forging. It is designed to withstand the fluctuating thermal loads encountered during contact with hot materials. It is recognized for its exceptional heat resistance, hardness, and wear resistance under thermal cycling conditions. It typically maintains hardness in the range of 50-60 HRC after heat treatment, ensuring optimal performance in extreme conditions.

What Are The Properties of Hot Work Tool Steel?

High Alloy Content

Hot work tool steels typically contain high levels of alloying elements like chromium, molybdenum, tungsten, and vanadium. These components improve the steel’s capacity to endure elevated temperatures and temperature fluctuations.

Excellent Heat Resistance

Hot work tool steel maintains its mechanical properties at high temperatures, typically between 480°C and 760°C (900°F to 1400°F). This makes it suitable for applications like die casting and extrusion.

Strong High-Temperature Toughness

Hot work tool steels are designed to retain toughness at high temperatures, making them resistant to cracking or brittleness. This toughness is essential when subjected to the intense thermal cycles typical in processes like forging and die casting.

Good Wear Resistance

The wear resistance of hot work tool steels is exceptional, making them ideal for applications that involve constant contact with hot metals, such as die casting, forging, and extrusion. This property helps extend tool life and reduces the frequency of replacements.

High Initial Cost, Long-Term Cost Efficiency

Hot work tool steels generally have a higher initial cost due to their alloy content and specialized properties. However, their long lifespan, reduced tool wear, and ability to withstand high temperatures make them cost-efficient in the long run for industrial applications.

Overview of Hot Work Tool Steel Types And Grades

Chromium Hot Work Tool Steels

Chromium hot work tool steels, generally classified between H10 to H19, are designed for high-temperature applications. The addition of elements like tungsten and molybdenum in grades such as H10 and H14 improves red hardness and hot strength, though this can slightly reduce toughness.

The key feature of these steels is their high chromium content, which enhances wear resistance, oxidation resistance, and toughness at elevated temperatures. The relatively low carbon content (0.35–0.40%) promotes toughness and allows for deep hardening, enabling air-hardening in sections up to 30 cm thick.

The main advantages of chromium-based hot work steels are:

- Heat Resistance: Excellent resistance to continued exposure to temperatures up to 540°C.

- Toughness: Balanced alloy content provides good toughness and ductility at high temperatures.

- Low Distortion: Air-hardening characteristics minimize distortion during heat treatment.

Tungsten Hot Work Tool Steels

Tungsten hot work tool steels, typically alloyed with tungsten, chromium, and sometimes vanadium, are known for their exceptional red hardness and resistance to high-temperature softening. However, their higher brittleness compared to chromium steels and the inability to cool with water are important considerations. The hardness of these steels typically ranges from 450 to 600 HV.

Key characteristics of tungsten steels include:

- Red Hardness: Superior ability to retain hardness under extreme heat conditions.

- Thermal Stability: Better resistance to softening at high temperatures compared to chromium-based steels.

- Brittleness: The high tungsten content can make these steels more brittle, requiring careful heat treatment and composition adjustments for toughness.

Molybdenum Hot Work Tool Steels

Molybdenum-based hot work tool steels are blended with molybdenum, chromium, vanadium, and occasionally tungsten, providing a mix of heat resistance and durability against thermal cracking. These steels share similarities with tungsten steels but offer better resistance to cracking due to thermal cycling.

Molybdenum steels require precise heat treatment to avoid issues like decarburization but are otherwise an excellent choice for tools exposed to extreme thermal conditions, such as die casting and forging.

The key benefits of molybdenum steels include:

- Heat Checking Resistance: Better resistance to cracks from repeated thermal cycling.

- High-Temperature Durability: Maintain hardness and resilience at high temperatures.

- Wear Resistance: Outstanding resistance to wear, making them ideal for high-stress, high-heat conditions.

Chemical Composition of Hot Work Tool Steel Grades

| AISI | C | Cr | V | W | Mo | Co |

| H10 | 0.4 | 3.25 | 0.4 | – | 2.5 | – |

| H11 | 0.35 | 5 | 0.4 | – | 1.5 | – |

| H12 | 0.35 | 5 | 0.4 | 1.5 | 1.5 | – |

| H13 | 0.35 | 5 | 1 | – | 1.5 | – |

| H14 | 0.4 | 5 | – | 5 | – | – |

| H19 | 0.4 | 4.25 | 2 | 4.25 | – | 4.25 |

| H21 | 0.35 | 3.5 | – | 9 | – | – |

| H22 | 0.35 | 2 | – | 11 | – | – |

| H23 | 0.3 | 12 | – | 12 | – | – |

| H24 | 0.45 | 3 | – | 15 | – | – |

| H25 | 0.25 | 4 | – | 15 | – | – |

| H26 | 0.5 | 4 | 1 | 18 | – | – |

| H42 | 0.6 | 4 | 2 | 6 | 5 | – |

What Is Hot Work Tool Steel Used For?

Hot work tool steel is primarily used in high-temperature applications, such as:

- Die Casting: For molds that shape molten metals.

- Extrusion: In forming processes where material is forced through a die.

- Drop Forging: For tools that shape metal under high pressure and heat.

- Glass Manufacturing: In molds and tools exposed to high heat during glass production.

- Pipe Manufacturing: For tools that form and shape metal pipes at elevated temperatures.

- Stamping and Forming: In high-temperature processes requiring precise shaping of metal parts.

Tailored Hot Work Tool Steel for Your Project

Investing in the right hot work tool steel ensures your tools perform reliably under the harshest conditions. SteelPro Group offers a wide range of high-performance steels, including custom sizes and tailored alloys, to meet your specific needs.

Reach out to us today to learn how our hot work tool steels can transform your manufacturing process.