Contents

Water Hardening Tool Steel | W1 | W2 | W3 Steel

- John

At SteelPro Group, our Water Hardening Tool Steel offers the perfect balance of durability, machinability, and cost-effectiveness, making it ideal for tools like cutting blades, punches, and dies.

What Is Water Hardening Tool Steel?

Water Hardening Tool Steel is a type of carbon steel that hardens when quenched in water, primarily composed of carbon with a content ranging from 0.60% to 1.40%. It includes grades like W1, W2, and W3. Although it offers ease of machining and cost-effectiveness, it has lower resistance to high-temperature softening. It is suitable for tools that require moderate wear resistance but not extreme heat resistance. Common applications include cutting tools, dies, and punches.

Overview of Water Hardening Tool Steel Grades

Water Hardening Tool Steel is typically divided into three main grades: W1, W2, and W3. The distinction between these grades is based on the variation in carbon content and small adjustments in alloying elements.

W1 Steel (0.60% – 1.00% Carbon)

W1 steel is the most basic grade, offering a carbon content between 0.60% and 1.00%. This grade is characterized by its simplicity, with minimal alloying elements. It’s valued for its ease of machinability, but its lack of alloying elements means it has lower wear resistance and toughness compared to higher grades.

Applications: Used for tools like hacksaw blades, chisels, and general hand tools where moderate hardness and machinability are required.

W2 Steel (0.90% – 1.20% Carbon, Chromium Added)

W2 steel features a carbon range of 0.90% to 1.20%, with the addition of small amounts of chromium to improve wear resistance and hardenability. This higher carbon content allows for a deeper hardening depth compared to W1. However, it is still not suitable for high-temperature environments.

Applications: Suitable for punches, dies, cold-heading dies, and light to medium-duty stamping tools requiring better wear resistance.

W3 Steel (1.20% – 1.40% Carbon, Chromium and Vanadium Added)

W3 steel has the highest carbon content among the three, ranging from 1.20% to 1.40%. It also includes chromium and vanadium, which significantly improve its hardness, wear resistance, and toughness. The addition of vanadium refines the grain structure, enhancing toughness and reducing brittleness. It offers better resistance to high-temperature softening than W1 and W2, though it is less machinable due to its higher carbon and alloy content.

Applications: Ideal for heavy-duty tools like high-performance cutting tools, forging dies, and punching tools exposed to moderate heat and wear.

Chemical Composition of Water Hardening Tool Steel Grades

| Element | W1 | W2 | W3 |

| Carbon (C) | 0.70-1.50 | 0.85-1.50 | 1.05-1.15 |

| Manganese (Mn) | 0.10-0.40 | 0.10-0.40 | 0.10-0.40 |

| Silicon (Si) | 0.10-0.40 | 0.10-0.40 | 0.10-0.40 |

| Chromium (Cr) | 0.15 max | 0.15 max | 0.40-0.60 |

| Nickel (Ni) | 0.20 max | 0.20 max | 0.20 max |

| Molybdenum (Mo) | 0.10 max | 0.10 max | 0.10 max |

| Tungsten (W) | 0.15 max | 0.15 max | 0.15 max |

| Vanadium (V) | 0.10 max | 0.15-0.35 | 0.10 max |

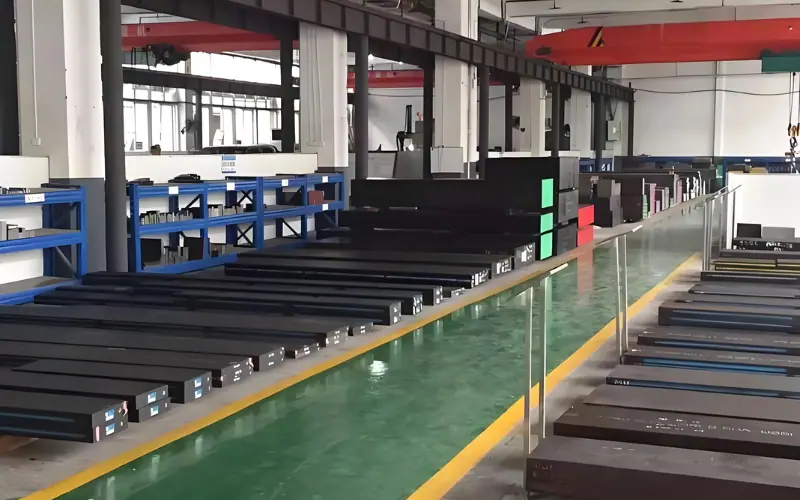

SteelPro Group provides Water Hardening Tool Steel in a variety of forms, including plates, bars, and rods. We also offer precision machining services to deliver parts ready for use, including cutting, milling, turning, and grinding.

What Are The Properties of Water Hardening Tool Steel?

Carbon Content: Water Hardening Tool Steel typically has a carbon content ranging from 0.60% to 1.40%, with popular grades often around 1.00%. The carbon content contributes to its hardness but also influences its hardening depth and machinability.

Shallow Hardening: One of the defining characteristics of Water Hardening Tool Steel is its shallow hardening nature. It forms a hardened surface layer when quenched in water, but the hardness does not penetrate deeply into thicker sections. This results in a hardened outer shell and a softer, re-softened core in thicker sections (over 13 mm).

Toughness: Despite its shallow hardening, Water Hardening Tool Steel has good toughness, especially when vanadium is added to maintain fine grain structure. This toughness helps prevent cracking under stress and makes the steel more resistant to chipping.

Wear Resistance: The addition of chromium can enhance the wear resistance of Water Hardening Tool Steel. However, compared to other high-carbon tool steels with higher alloying elements, its wear resistance may be lower, especially under heavy-duty conditions.

Low Heat Resistance: Water Hardening Tool Steel exhibits relatively low resistance to softening at high temperatures. This makes it less suited for applications where the steel will be exposed to sustained high temperatures, as it can lose hardness more rapidly compared to other tool steels.

Machinability: With its simpler composition, Water Hardening Tool Steel is relatively easy to machine. It allows for the fabrication of tools with less complex processing, making it a cost-effective choice for many general tool applications.

Quenching Sensitivity: Water is the primary medium for quenching, and it can lead to rapid cooling rates, which results in the formation of a hard surface. However, the quick quenching can also introduce the risk of distortion or cracking, especially if the part geometry is complex.

Cost-Effectiveness: Given its simpler alloying structure and the lower cost of water quenching, Water Hardening Tool Steel is a more economical choice compared to higher alloyed tool steels, making it attractive for less demanding applications where cost is a critical factor.

What Is Water Hardening Tool Steel Used For?

Water Hardening Tool Steel is primarily used for manufacturing tools that require moderate hardness and wear resistance but are not exposed to high temperatures. It’s also used in applications where cost-effectiveness and ease of fabrication.

- Hacksaw Blades

- Woodworking Chisels

- Hand Scrapers

- Small Stamping Dies

- Cold Heading Dies

- Punching Dies for Sheet Metal

- Drill Bits for Low to Medium-Strength Materials

Enhance Your Tools with Custom Water Hardening Tool Steel

SteelPro Group offers not only high-quality Water Hardening Tool Steel but also comprehensive machining and processing services. Our precision capabilities ensure your materials meet exact specifications for optimal performance.