Contents

S280GD Steel: Properties, Processes, Machining, Applications

- John

Because we strive for excellence from chemical composition to versatile surface treatment and coating options, our S280GD stands out in strength, corrosion resistance and ease of processing. Whether you are a small steel mill or a large manufacturing company, S280GD galvanized steel can provide stable and reliable raw material support for your production.

Let’s take a deeper look at its advantages and applications to let you know more clearly why it is your ideal choice for purchasing steel.

What is S280GD Steel?

S280GD is a non-alloy structural steel, made of about 98-99% iron and 0.1-0.2% carbon, meeting EN 10346 with a minimum yield strength of 280 MPa. It is a flat-rolled steel, typically hot-dip galvanized for corrosion resistance. In S280GD, “S” denotes structural steel, “280” the yield strength, and “GD” galvanization. It comes with finishes like +Z (zinc) and +ZF (zinc-iron), suitable for construction, automotive, and light engineering. Similar to FeE280G, it has an EU steel number of 1.0244.

How Does S280GD Perform In Extreme Temperatures?

SteelPRO Group’s S280GD galvanized steel, especially the version with +AZ (aluminum zinc) coating, performs well in high temperature environments and maintains structural integrity. Our products are precisely controlled to ensure reliable performance in extreme temperatures.

What Is The Lifespan Of S280GD+Z275 In Outdoor Applications?

S280GD+Z275 galvanized steel, with a 275 g/m² zinc layer, provides excellent corrosion resistance and can be used in outdoor environments for more than 20 years. SteelPRO Group’s strict quality control ensures its long-term stability in a variety of environments.

Chemical Composition of S280GD Steel

| Element | Content (%) |

| Iron, Fe | 98-99 |

| Carbon, C | 0.1-0.2 |

| Manganese, Mn | ≤ 1.2 |

| Phosphorus, P | ≤ 0.12 |

| Sulfur, S | ≤ 0.045 |

| Silicon, Si | ≤ 0.5 |

| Nitrogen, N | ≤ 0.012 |

| Aluminum, Al | ≤ 0.015 |

Mechanical Properties of S280GD Steel

| Property | Metric | Imperial |

| Tensile Strength | 360-440 MPa | 52-64 ksi |

| Yield Strength | ≥ 280 MPa | ≥ 40.6 ksi |

| Brinell Hardness | 110-140 HB | 110-140 HB |

| Rockwell Hardness | 65-75 HRB | 65-75 HRB |

| Vickers Hardness | 120-140 HV | 120-140 HV |

| Elongation | 20-26% | 20-26% |

| Elastic Modulus | 210 GPa | 30,500 ksi |

| Fracture Elongation (≤ 0.7mm) | ≥ 16% | ≥ 16% |

| Fracture Elongation (> 0.7mm) | ≥ 18% | ≥ 18% |

| Coating Adhesion (Bend Radius) | 0T-2T (0-2x thickness) | 0T-2T (0-2x thickness) |

Production Processes of S280GD Steel

Our S280GD steel from SteelPRO Group uses a series of high-standard production processes to ensure that each batch of products can achieve the best performance and quality. The following are the main steps of our S280GD production process:

- Raw material smelting: We first melt iron ore and carbon at a high temperature of about 1500°C to produce liquid steel. This is the basis of the entire production process.

- Continuous casting: The liquid steel flows into the casting equipment, where it gradually cools and solidifies into a billet, which becomes the basis material for the next step of processing.

- Hot rolling: The billet is heated to about 1100°C and rolled through a rolling mill to the required thickness. This process lays a solid foundation for the subsequent processing of the steel.

- Cold rolling: The hot-rolled steel is quickly cooled and rolled again at room temperature to ensure that the surface of the steel is smooth and the size is accurate.

- Annealing: The cold-rolled steel is heated to a temperature of 700-900°C and annealed to improve the ductility of the steel and reduce internal stress.

- Galvanizing: Finally, the steel is coated with a layer of zinc at about 450°C through a hot-dip galvanizing process, which effectively improves its corrosion resistance and ensures long-term durability.

Unlike S250GD steel, S280GD uses higher rolling pressures and faster cooling rates during the production process to achieve a yield strength of 280 MPa. S250GD achieves a yield strength of 250 MPa through lower pressures and slower cooling rates.

Machining of S280GD Steel

SteelPRO Group is committed to providing customers with high-quality, easy-to-process steel. Our S280GD steel is not only superior in performance, but also very reliable in processing. If you want to further process our S280GD, you can refer to the following tips:

Cutting

- Suitability: S280GD is well suited to common methods such as laser cutting and plasma cutting, and you can easily make high-precision cuts.

- Note: Due to the high strength of S280GD, you may need to use sharper tools and slow down the cutting speed appropriately to obtain a finer cut effect.

- Application areas: Whether it is the automotive manufacturing industry or the construction industry, S280GD can meet the needs of precise cutting, helping you improve production efficiency and ensure quality.

Cold bending

- Process characteristics: S280GD steel has excellent ductility and structural stability, which is very suitable for cold bending.

- Limitations: If you need to bend a small radius, you may need to preheat or heat the steel, but don’t worry, our steel is also very stable in this regard and you can easily handle it.

- Applications: S280GD is widely used in construction, automotive, metalworking and other fields, helping you easily create complex curved parts, not only improving production efficiency, but also ensuring the quality and durability of parts.

Stamping

- Strength and flexibility: With its excellent yield strength, S280GD can ensure high quality and no cracks during the stamping process.

- Tool requirements: Since the stamping process puts a certain amount of pressure on the equipment, we recommend the use of durable tools. SteelPRO Group’s S280GD can easily cope with these requirements to ensure smooth production.

- Applications: Suitable for large-scale production of small precision parts, it can still maintain efficient and stable performance during mass production.

Welding

- Welding methods: S280GD is very suitable for common welding methods such as MIG welding, TIG welding and spot welding. Regardless of the welding process, our steel can provide reliable welding results.

- Welding preparation: Surface cleaning and preheating can further improve the welding quality and ensure a solid and reliable welded joint.

- Note: During the welding process, proper adjustment of heat and speed can effectively avoid excessive thermal stress and deformation and maintain the strength and stability of the welding part.

Surface Treatment of S280GD Steel

We attach great importance to the surface quality of each batch of S280GD steel, because we know that high-quality surface treatment can greatly improve the durability and beauty of steel. The following are some common surface treatment options we provide:

- Surface Quality Grades: We provide different surface quality grades, including FB, FC, FD, NA, MA and MC, each grade has its own specific surface characteristics, suitable for different aesthetic and functional requirements.

- Coating Types:

- +Z: Zinc coating, provides basic corrosion resistance; used in general applications.

- +ZF: Zinc-iron alloy coating, offers enhanced durability; suited for construction and automotive.

- +ZA: Zinc-aluminum coating, improves corrosion resistance and wear; applied in harsh environments.

- +ZM: Zinc-magnesium coating, increases resistance to weather and chemicals; popular in marine and industrial settings.

- +AZ: Aluminum-zinc coating, strong against corrosion and heat; suitable for roofing and exterior structures.

- +AS: Aluminum-silicon coating, withstands high temperatures; ideal for heat-exposed components.

- Other Treatments: We also offer options such as chromating, passivation, oil sealing and color coating to provide your product with additional protection while also improving its appearance.

Characteristics of S280GD Steel

Compared with other brands on the market, our S280GD steel provides higher reliability and longer service life through stricter production processes and innovative surface treatments.

Higher yield strength

The yield strength of S280GD steel reaches 280 MPa, which is 30% higher than the common S250GD steel. This means that our steel can withstand greater loads, ensuring the stability of the structure under extreme conditions, and is suitable for projects that require high durability and load capacity, such as construction and the automotive industry.

Excellent corrosion resistance

Our S280GD uses advanced coatings such as +Z and +ZM, and its corrosion resistance far exceeds that of ordinary galvanized steel. Even in marine or harsh environments, S280GD can maintain a long service life, greatly reducing maintenance and replacement costs.

High cost performance and production efficiency

Although the strength and corrosion resistance of S280GD exceed similar products, its production process is similar to S250GD, ensuring higher cost performance. You can enjoy stronger performance while still maintaining reasonable costs, suitable for mass production and long-term use.

Superior processing performance

S280GD not only has excellent strength, but also has good ductility, and can be efficiently cold-bent and stamped. Compared with other brands of steel, it is easier to form and less prone to cracking, helping you save cost and time in production.

Welding and customization advantages

Our S280GD steel has good weldability and can be welded directly without complicated pretreatment. Compared with other steels, S280GD performs more stably during the welding process, reduces processing difficulty, and is suitable for high-precision customized parts.

Excellent heat reflection performance

S280GD steel equipped with aluminum-zinc coating has significantly better heat reflection ability than many brands on the market. It is particularly suitable for roof and facade insulation materials, which improves the energy efficiency of buildings and reduces later maintenance.

Are There Alternatives To S280GD For Higher Strength Needs?

For projects that require higher strength, you can choose grades like our S350GD or S355MC. These materials offer increased yield strength while retaining the corrosion resistance and machinability of S280GD.

Application of S280GD Steel

Our S280GD has a wide range of uses, including but not limited to the following scenarios. You can leave us a message about your target location or specific needs, and our experts will help you choose the right steel.

- Construction: Beams, wall panels, and structural supports.

- Automotive: Car frames, chassis components, and body panels.

- Appliances: Refrigerator bodies, washing machine drums, and oven exteriors.

- Roofing and Cladding: Roofing sheets, facade panels, and wall cladding.

- HVAC Systems: Air ducts, ventilation hoods, and heat exchangers.

- Agricultural Equipment: Tractors, plows, and storage bins.

- Storage Tanks: Water tanks, fuel containers, and chemical storage units.

- Electrical Enclosures: Transformer cases, switchgear boxes, and control cabinets.

S280GD+Z275 Steel: Enhanced Protection for Challenging Environments

S280GD+Z275 isn’t just about added corrosion resistance—it’s a smart choice for projects needing high durability. The 275 g/m² zinc layer transforms the steel’s performance in tough conditions, making it ideal for outdoor or humid environments.

Choosing S280GD+Z275 means you’re investing in long-lasting reliability. At SteelPRO Group, we’ve seen this grade excel in rugged construction, automotive, and agricultural uses where strength and endurance are essential. For reliable, resilient material, S280GD+Z275 stands out. Contact us to see how it can benefit your project.

How Does S280GD Compare In Cost To Similar Grades?

S280GD balances cost and performance well, often priced competitively compared to higher-strength or alloyed steels. It provides cost-efficiency in projects requiring durability without extreme load demands.

Reliable S280GD Steel Manufacturer

SteelPRO Group offers a wide variety of S280GD steel products customized to satisfy various industrial requirements. Our selections include:

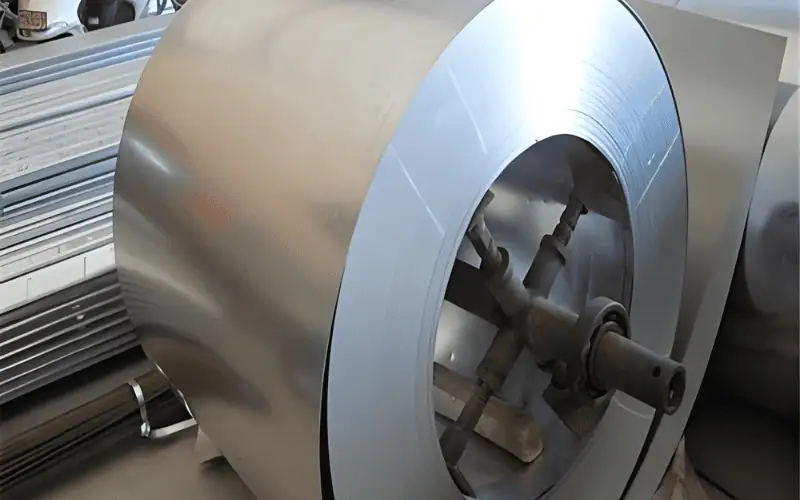

- Product Forms: custom-cut S280GD sheet and coils, S280GD pipes, designed to suit various manufacturing and construction applications.

- Processing Options: Precision slitting, custom cutting, and length-specific processing to ensure high flexibility and quality in meeting client specifications.

- Surface Structures: Choose from regular spangle, minimum spangle, zero spangle, and big spangle surfaces to meet different aesthetic and functional requirements.