Contents

P20S | 1.2312 | P20+S Tool Steel From SteelPro Group Supplier

- John

With almost 20 years of experience, SteelPro Group offers premium 1.2312 steel (P20S) in various forms, including round bars, square bars, and plates. Our emphasis on excellence and accuracy guarantees that our products adhere to top-tier quality.

What Is 1.2312 Tool Steel?

1.2312 steel is a high-quality plastic mold steel, developed from 1.2311 steel(P20), with enhanced machinability. It incorporates Cr-Mn-Mo as strengthening alloy elements and a higher sulfur content (0.05-0.1%), which improves cutting performance. This steel provides a 30% increase in milling speed and a 300% increase in drilling speed compared to 1.2311. It is ideal for plastic mold applications, injection molding, and tooling. We deliver it in a pre-hardened state (28-34 HRC).

1.2312 Steel Equivalent

Here is the equivalent steel information in table format:

| Standard | Equivalent Steel |

| GB/T 1299 | 4Cr2Mn1MoS |

| ASTM A681 | P20+S |

| DIN EN ISO 4957 | 1.2312 |

| DIN 17350 | 40CrMnMoS 8-6 |

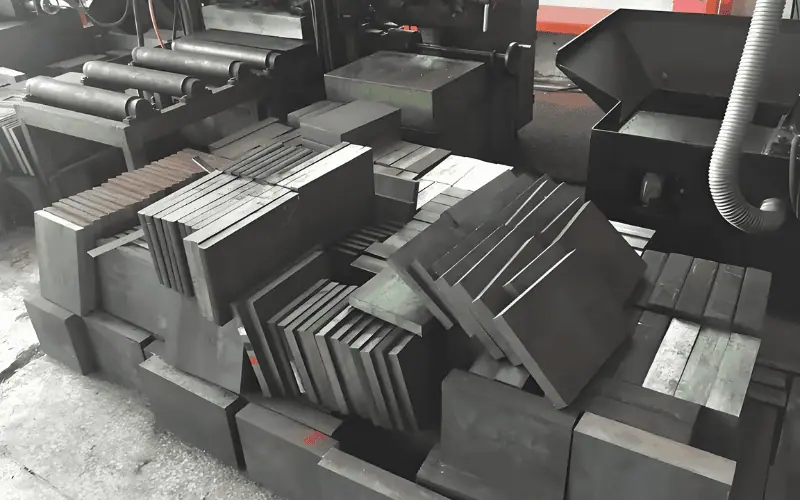

1.2312 Tool Steel Products Forms And Supply Range

We offer carefully tested 1.2312 steel products that meet the highest industry standards. Our products undergo strict tolerance controls to ensure exceptional quality and precision.

In addition to the sizes listed below, we are happy to provide custom dimensions tailored to your specific needs.

| Product Form | Size Range (Metric) | Size Range (Imperial) |

| Round Bars | Diameter: 20 mm to 500 mm | Diameter: 0.79″ to 19.69″ |

| Length: 3000 mm | Length: 9.84′ | |

| Plates | Thickness: 5 mm to 150 mm | Thickness: 0.20″ to 5.91″ |

| Width: 100 mm to 1000 mm | Width: 3.94″ to 39.37″ | |

| Length: 2000 mm to 6000 mm | Length: 78.74″ to 236.22″ | |

| Flat Bars | Thickness: 10 mm to 100 mm | Thickness: 0.39″ to 3.94″ |

| Width: 40 mm to 300 mm | Width: 1.57″ to 11.81″ | |

| Length: 3000 mm | Length: 118.11″ | |

| Square Bars | Size: 20 mm to 150 mm | Size: 0.79″ to 5.91″ on each side |

1.2312 Tool Steel Chemical Composition

| Element (Symbol) | Composition |

| Carbon (C) | 0.40 % |

| Chromium (Cr) | 1.9 % |

| Iron (Fe) | 95.628 – 95.64 %, as balance |

| Manganese (Mn) | 1.5 % |

| Molybdenum (Mo) | 0.20 % |

| Phosphorus (P) | ≤ 0.012 % |

| Silicon (Si) | 0.30 % |

| Sulfur (S) | 0.060 % |

Advantages of Sulfur Content in 1.2312 Steel

Improved Machinability: The addition of sulfur makes the steel easier to machine, reducing tool wear and improving overall machining efficiency.

Extended Tool Durability: Improved machinability results in a longer tool lifespan, minimizing the need for frequent tool replacements and reducing downtime.

Faster Processing: The improved cutting characteristics allow quicker processing speeds, increasing overall productivity.

Disadvantages of Sulfur Content in 1.2312 Steel

Reduced Weldability: Due to the higher sulfur content, welding 1.2312 steel requires special care, as sulfur can lead to cold cracking. Higher pre/post heating temperatures (350°C – 660°F) are necessary to avoid this issue.

Surface Quality Challenges: The sulfur can cause rougher surface finishes, making it unsuitable for high-quality polishing. It also makes etching and EDM less effective, so alternative steels like 1.2311 or 1.2738 are preferred for fine surface requirements.

Decreased Toughness: High sulfur content can slightly reduce the overall toughness and ductility of the steel, making it more prone to brittleness under certain conditions.

1.2312 Tool Steel Physical Properties

| Property | Metric Value | Imperial Value |

| Density | 7.83 g/cc | 0.283 lb/in³ |

| Thermal Conductivity | 34.0 W/m·K | 236 BTU·in/hr·ft²·°F |

| Melting Point | 1425-1470 °C | 2597-2678 °F |

| Specific Heat Capacity | 0.46 J/g·K | 0.11 BTU/lb·°F |

| Electrical Resistivity | 0.50 µΩ·cm | 0.50 × 10⁻⁶ Ω·in |

The table below outlines the coefficient of thermal expansion (CTE) for 1.2312 steel at various temperature intervals.

| CTE (Metric) | CTE (Imperial) | Temper (Metric) | Temper (Imperial) |

| 12.2 µm/m-°C | 6.80 µin/in-°F | 21.1 – 93.3 °C | 70.0 – 200 °F |

| 13.0 µm/m-°C | 7.20 µin/in-°F | 21.1 – 204 °C | 70.0 – 400 °F |

| 13.7 µm/m-°C | 7.60 µin/in-°F | 21.1 – 302 °C | 70.0 – 575 °F |

1.2312 Tool Steel Mechanical Properties

| Property | Metric Value | Imperial Value |

| Hardness | 300 HB | 300 HB |

| Yield Strength (Rp 0.2) | 850 MPa | 123 ksi |

| Tensile Strength (Rm) | 960 MPa | 139 ksi |

| Elongation | 10 % | 10 % |

| Reduction of Area | 45 % | 45 % |

| Impact Energy (KCV at 20°C) | 20 J | 20 J |

| Elastic Modulus | 205 GPa | 29733 ksi |

Heat Treatment of 1.2312 Tool Steel

We supply 1.2312 steel in an annealed condition, offering superior machinability and toughness. Ready for your most demanding applications, our heat-treated steel ensures optimal hardness and consistent results, saving you time and effort in post-processing.

Forging

Heat 1.2312 steel to an initial temperature of 1050-1100°C (1922-2012°F) and forge it down to a final temperature of 850°C (1562°F). Ensure the forging ratio is above 4:1 for proper material deformation.

After forging, allow the steel to cool as gradually as possible in the sand. We also recommend performing annealing after forging to improve machinability.

Annealing

Heat 1.2312 steel to 760-790°C (1400-1454°F) and allow it to cool in the furnace. The hardness after annealing should not exceed 241 HB.

Stress Relieving

Stress relieving is done to reduce internal stresses in the material. Heat the steel to 600-650°C (1112-1202°F) and then cool it in air. This process does not significantly affect the hardness but improves dimensional stability.

Hardening

Preheating:

Preheat 1.2312 steel to 840-860°C (1544-1580°F) to prepare for hardening.

Austenitizing:

Rapidly heat the steel to 840-880°C (1544-1616°F) for austenitizing. This temperature range allows the steel’s microstructure to transform into austenite, ensuring maximum hardness.

Quenching:

After reaching the austenitizing temperature, quench the steel in oil. Oil quenching is preferred as it provides uniform cooling and reduces the risk of cracking. The steel’s maximum hardness after quenching can reach 52 HRC.

Tempering

After quenching, temper the steel between 600-650°C (1112-1202°F). Hold the steel at this temperature and cool it in the air. Tempering reduces the hardness to a range of 28-36 HRC, balancing hardness and toughness for improved performance.

We suggest double tempering for optimal results to obtain the optimal balance of hardness and toughness.

The chart below illustrates the hardness of 1.2312 steel after tempering at different temperatures.

| Hardness (HRC) | Tempering Temperature (°C) | Tempering Temperature (°F) |

| 51 | 100 | 212 |

| 50 | 200 | 392 |

| 48 | 300 | 572 |

| 45 | 400 | 752 |

Machining

1.2312 steel is easy to machine, especially when using high-speed steel or carbide tools. Thanks to its controlled sulfur content, it offers better machinability compared to 1.2311 steel. Here is what you can expect:

- Tool Life: You can achieve up to 500% longer tool life while maintaining the same cutting speed.

- Drilling Speed: Drilling becomes 300% faster.

- Milling Speed: Milling speed increases by 30%.

You can apply the same cutting conditions used for 1.2311, with some nice upgrades:

- Carbide tools boost milling speed by 30%.

- High-speed steel tools make drilling 300% faster.

These improvements make machining 1.2312 steel more efficient, helping you save time and get better results.

1.2312 Tool Steel Applications

1.2312 steel is widely used in various industries, particularly for plastic mold making, due to its excellent machinability, toughness, and pre-hardened condition. Here are the typical uses of 1.2312 steel:

- Injection Molds

- Blow Molds

- Press Molds

- Die-casting Molds

- Core Pins/Inserts

Unlock the Full Potential of Your 1.2312 Steel

With a variety of processing options available, including annealing, pre-hardening, nitriding, and grinding, we ensure that your 1.2312 steel is tailored to meet your exact requirements. Additionally, we also supply H13 tool steel, ideal for high-temperature applications.

Get in touch with us today to learn how we can support your projects with our expertise and high-quality products.