Contents

Oil-Hardening | O1 Tool Steel: Properties, Process and Uses

- John

What Is O1 Tool Steel?

O1 tool steel is a high-carbon, oil-hardening steel that meets international standards such as AISI Type O1 and UNS T31501. It is classified as a cold-work tool steel designed to withstand high stress and impact while maintaining dimensional stability. O1 is commonly available in ground stock, drill rods, and bars, and is widely used for manufacturing cutting tools, dies, and jigs due to its excellent wear resistance and toughness.

What Is O1 Tool Steel Equivalent To?

Common equivalents for O1 include:

- UNS T31501-Unified Numbering System

- AISI Type O1 – American Iron and Steel Institute

- DIN 1.2510 – German Standard

- 100MnCrW4 – European Standard

- SKS3 – Japanese Standard

Key Features of O1 Tool Steel

O1 tool steel, known for its elevated carbon levels, delivers superior hardness and abrasion resistance. It maintains dimensional stability and good toughness under high stress and impact. Additionally, O1 is relatively straightforward to machine and form, making it a favored option for creating bespoke tools and molds.

The following tables provide detailed data information for O1 tool steel:

Chemical Composition of O1 Tool Steel

| Element | Composition (%) |

| Carbon (C) | 0.90 – 1.00 |

| Manganese (Mn) | 0.30 – 0.50 |

| Chromium (Cr) | 0.40 – 0.60 |

| Molybdenum (Mo) | 0.15 – 0.30 |

| Silicon (Si) | 0.10 – 0.35 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.030 |

Physical Properties of O1 Tool Steel

| Property | Metric Value | Imperial Value |

| Density | 7.85 g/cm³ | 0.284 lb/in³ |

| Melting Point | 1425 – 1540 °C | 2597 – 2804 °F |

| Thermal Expansion Coefficient | 11.6 × 10⁻⁶ /°C | 6.44 × 10⁻⁶ /°F |

| Specific Heat | 0.460 J/g·°C | 0.110 Btu/lb·°F |

| Electrical Conductivity | 4.5 × 10⁶ S/m | 7.8 × 10⁵ S/in |

| Thermal Conductivity | 25.9 W/m·K | 14.96 Btu·ft/h·°F |

| Poisson’s Ratio | 0.3 | 0.3 |

| Modulus of Elasticity | 210 GPa | 30.5 × 10⁶ psi |

Mechanical Properties of O1 Tool Steel

| Property | Metric Value | Imperial Value |

| Yield Strength | 1,100 – 1,300 MPa | 159,500 – 188,550 psi |

| Tensile Strength | 1,500 – 1,700 MPa | 217,500 – 246,500 psi |

| Elongation | 6 – 12 % | 6 – 12 % |

| Hardness | 58 – 64 HRC | 58 – 64 HRC |

| Impact Toughness | 5 – 10 J | 3.69 – 7.38 ft·lb |

| Bending Strength | 2,100 – 2,400 MPa | 304,500 – 348,000 psi |

| Fatigue Strength | 500 – 800 MPa | 72,500 – 116,000 psi |

| Modulus of Elasticity | 210 GPa | 30.5 × 10⁶ psi |

| Fracture Toughness (K_IC) | 55 – 60 MPa·√m | 50 – 55 ksi·√in |

How To Heat Treat O1 Tool Steel?

Annealing

Annealing is a great way to soften O1 steel and relieve any internal stresses. It makes the steel easier to machine and prepares it for the next steps in heat treatment.

- Heating: Gradually heat the steel to 1450°F (790°C) and hold it at this temperature.

- Cooling: Once soaked, cool the steel at about 25°F per hour (14°C per hour) down to 900°F (480°C), then air cool to room temperature.

- Resulting Hardness: After annealing, O1 should have a Brinell hardness of 221.

Stress Relief (For Unhardened Material)

Stress relief is used to reduce internal stresses in O1 before hardening, which helps prevent deformation or cracking.

- Heating: Slowly heat the steel to 1250°F (677°C).

- Soaking: Soak for about two hours per inch (25.4 mm) of thickness.

- Cooling: Allow the steel to cool slowly (furnace cooling is ideal) to room temperature.

Normalizing

Normalizing is used to refine the grain structure and relieve stresses before hardening, particularly for blades and thicker sections. If you want to avoid surface decarburization or scale, using high-temperature anti-scale coatings like ATP-641 or Turco will help.

- Cycle 1: Heat to 1650°F (898°C) and hold for 10-15 minutes.

- Cycle 2: Reduce the temperature to 1500°F (815°C) and hold again for 10-15 minutes.

- Cycle 3: Finally, lower the temperature to 1350°F (732°C) and hold for another 10-15 minutes.

- Cooling: Once the material cools to black and becomes magnetic, it can be cycled again. Always handle the hot steel with care.

Austenitizing

Austenitizing is the key step for hardening O1 steel, where it is heated to high temperatures to convert the microstructure and prepare for quenching.

- Heating: Heat the steel to 1475°F to 1500°F (802°C to 815°C). Make sure the steel is heated evenly.

- Soaking: Hold the steel at the austenitizing temperature for about 30 minutes per inch (25.4mm) of thickness.

- Soak Time: If using a forge, reduce the soak time to the minimum, as a forge may not maintain precise temperature control.

Quenching

After austenitizing, the steel needs to be quenched to cool rapidly and lock in the hardness. Oil quenching is the most common method for O1 steel.

- Quenching Medium: Use Parks 50 or another suitable quenching oil. Slower quenching oils may result in lower hardness.

- Cooling: Quench the steel in oil until it cools to 150-200°F (66-93°C).

Be careful when handling, as quenching may lead to distortion or cracking, particularly if there are noticeable variations in section thickness or sharp internal corners.

Tempering

Tempering is the last phase of heat treatment, during which the steel is reheated to a lower temperature to lessen brittleness and fine-tune its hardness.

- Heating: After quenching, temper O1 by heating it to a range between 300°F and 500°F (150°C to 260°C), depending on the desired hardness.

- Soaking: Soak the steel at the selected temperature for 2 hours per inch of thickness.

- Cooling: After tempering, cool the steel in air to room temperature.

Hardness After Tempering: The final hardness will be around Rockwell C 58-64, depending on the tempering temperature.

Applications of O1 Tool Steel

O1 is particularly valued in industries where high wear resistance, low distortion during hardening, and cost-effectiveness are critical factors, such as automotive, aerospace, and manufacturing industries. It is widely used in the manufacture of:

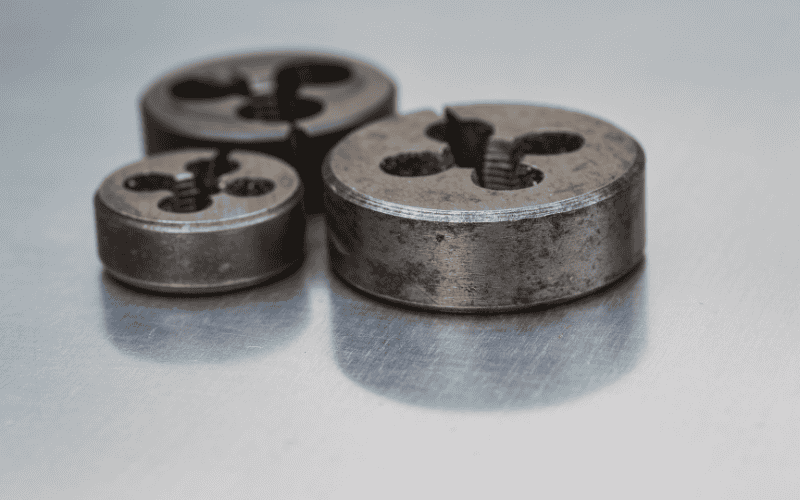

- Blanking Dies: For punching and shaping materials.

- Bushings: Used in machinery and automotive components.

- Forming Dies: Essential for shaping metals into parts.

- Master Tools: For precise manufacturing operations.

- Forming Rolls: For the production of rolled materials.

- Gauges: For measuring and testing components.

- Trim Dies: For cutting excess material from a formed part.

Is O1 Steel Good For Knives?

Yes, O1 steel is great for knives! It offers excellent edge retention, toughness, and is easy to sharpen. Although it demands extra care to avoid rusting, it remains a preferred option for long-lasting, high-performance knives.

Products Forms of O1 Tool Steel

Bars and Rods

O1 tool steel is widely available in round bars, square bars, and rectangular bars. These are often used for machining, manufacturing cutting tools, dies, and jigs.

- Diameter: 1/8 inch (3.175mm) to 12 inches (304.8mm)

- Length: Standard lengths typically range from 3 feet (0.91m) to 20 feet (6.1m), depending on the supplier.

Ground Flat Stock

Precision-ground flat stock is available for applications requiring highly accurate dimensions and a fine surface finish. This form is commonly used in tool making and precision machining.

- Thickness: 1/16 inch (1.6mm) to 3/4 inch (19.05mm)

- Width: 1 inch (25.4mm) to 12 inches (304.8mm)

- Length: Varies, typically ranging from 2 feet (0.61m) to 6 feet (1.83m).

Drill Rods

O1 drill rods are used to produce cutting tools and precision components. These are often available in ground or polished forms for enhanced machinability.

- Diameter: 1/8 inch (3.175mm) to 3 inches (76.2mm)

- Length: Usually 36 inches (0.91m) to 72 inches (1.83m).

Flat Stock

This form is often used for manufacturing dies, blanks, and punches.

- Thickness: 1/8 inch (3.175mm) to 3 inches (76.2mm)

- Width: 1 inch (25.4mm) to 12 inches (304.8mm)

- Length: Varies depending on supplier, typically available in 3 feet (0.91m) to 12 feet (3.66m).

SteelPro Group provides custom size services to meet specific requirements, offering precise and tailored solutions for industries that need specialized dimensions for their operations.

High-Quality O1 Tool Steel

At SteelPro Group, we offer premium O1 tool steel in various forms including precision-ground flat stock, drill rods, and round bars. Our products are available in custom sizes to meet your specific needs. We also offer SKD11 steel, which has superior machinability.

We take pride in providing not only high-quality O1 tool steel but also unparalleled customer support. Let SteelPro Group be your go-to source for all things O1 tool steel—where performance meets precision.