A606 | Weathering Steel

A606 | Weathering Steel

A606 is an HSLA steel that meets ASTM A588 and ASTM A242 standards. Its prominent feature is its high resistance to atmospheric corrosion and aesthetic appeal. It is ideal for outdoor applications like bridges, buildings, and sculptures. It includes two main subgrades: A606-4 and A606-3, with A606-4 being the most commonly used due to its superior resistance.

SteelPro Group is a leading supplier of A606 weathering steel, specializing in custom sizes and high corrosion resistance.

Description

What is A606?

A606 is also known as COR-TEN steel, primarily composed of copper, chromium, nickel, and phosphorus. It is available in plates, sheets, and coils, processed by hot or cold rolling. A606 is classified into two subgrades: A606-4, which has higher resistance to atmospheric corrosion, and A606-3, often used in less severe environments.

Why Choose A606 Steel?

A606 weathering steel offers a balanced combination of corrosion resistance, strength, and workability, making it ideal for a wide range of outdoor applications. Compared to other weathering steels, A606-4 is more resistant to corrosion, especially in environments with frequent moisture exposure, while A606-3 provides a cost-effective solution for less harsh conditions. For projects requiring superior mechanical properties and resistance in extreme environments, A588 or A709 steels are better choices.

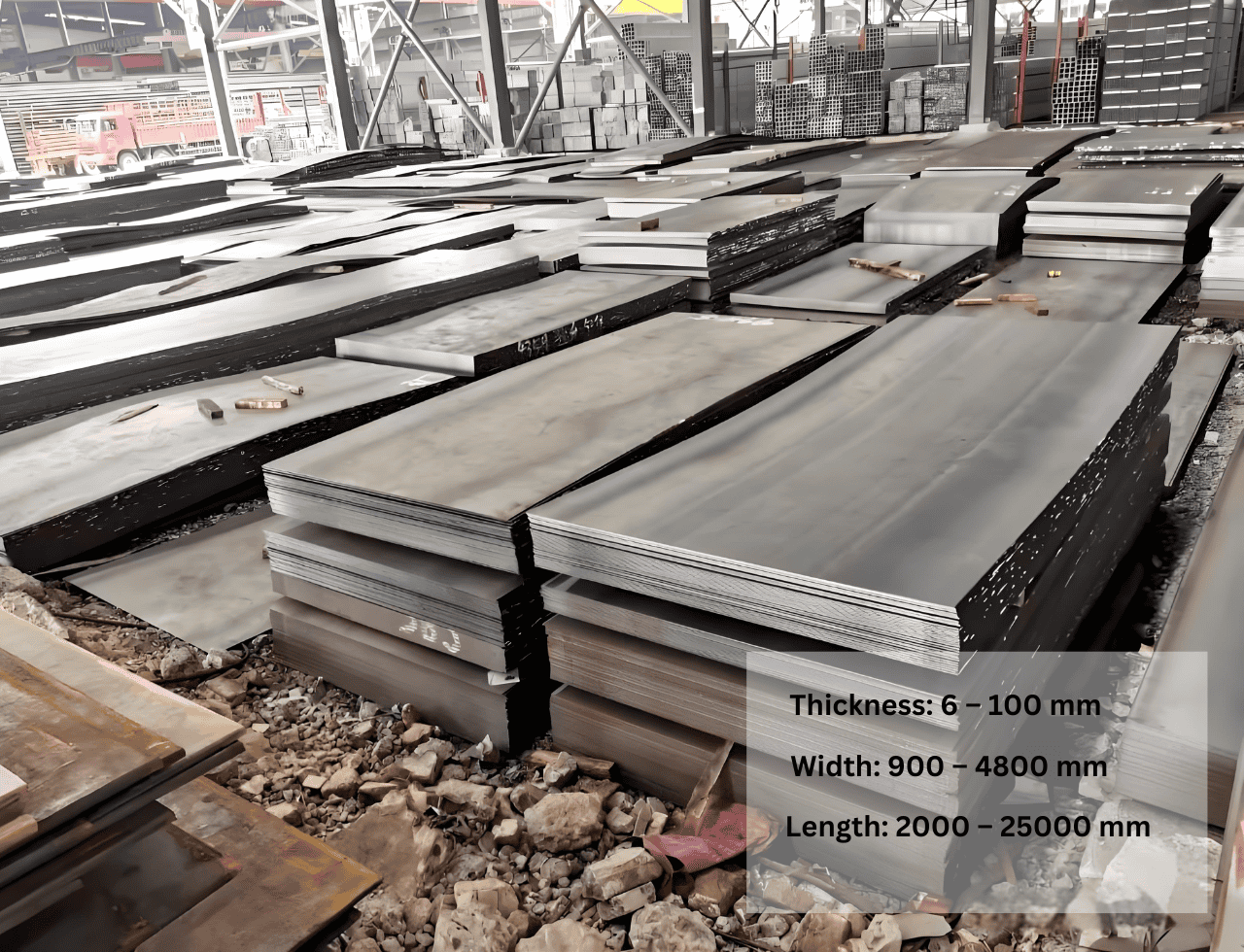

Choose us for A606 weathering steel with reliable corrosion resistance, fast delivery, and custom sizes. Our typical plate thickness ranges from 6 mm to 100 mm. Our material meets ASTM A588 and A242 standards, ensuring quality and cost-effective solutions for long-lasting projects.

Product Specification

| Category | Details |

| Quality Standard | ASTM A588, ASTM A242, EN 10025-5 |

| Certifications | ISO 9001, ISO 14001, BV, SGS, RoHS, ASTM A606, ASTM A242 |

| Thickness | 6-100mm |

| Width | 900-4800mm |

| Length | 3000-25000mm |

| Weight | Depends on length and width |

| Outer diameter (OD) | Pipes: 22 mm to 610 mm, Bars: 6 mm to 200 mm |

| Inner diameter (ID) | Pipes: 15 mm to 600 mm |

| Tolerances | Thickness: ±0.3 mm to ±2.0 mm, Width: ±5 mm to ±20 mm, Length: ±10 mm to ±50 mm |

| Technology | Hot Rolling, Drawing, Normalizing |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Shapes | Weathering Steel Plate, Weathering Steel Sheet, Pipes, Profiles |

| MOQ (Minimum Order Quantity) | 5 tons (according to the actual tonnage) |

| Lead Time | Typically 7-20 days (The larger the ordered tonnage, the longer the delivery time) |

| Price Terms & Payment | Based on customer requirements, T/T, L/C |

| Ports | Qingdao, Lianyungang, Dalian |

| Export Countries | Southeast Asia, Central Asia, Europe, Russia, South America, Middle East, etc. |

| Shipping Method | Offers Sea, Air and Customized Shipping |

Chemical Compositions

| Element | C | Mn | P | S | Si | Cu | Cr | Ni | Mo | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| % Range | 0.12 max | 0.80-1.25 | 0.035 max | 0.05 max | 0.20-0.60 | 0.25-0.55 | 0.40-0.65 | 0.65-1.00 | 0.20 max | 0.02 max |

Mechanical Properties

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 485-620 MPa | 70-90 ksi |

| Yield Strength | 345 MPa | 50 ksi |

| Brinell Hardness (HB) | 150-250 HB | 150-250 HB |

| Rockwell Hardness (HRC) | 50-60 HRC | 50-60 HRC |

| Vickers Hardness (HV) | 150-250 HV | 150-250 HV |

| Elongation | 20-25% | 20-25% |

| Elastic Modulus | 210 GPa | 30.5 x 10^6 psi |

Data After Normalizing Processing

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 520-670 MPa | 75-97 ksi |

| Yield Strength | 380-480 MPa | 55-70 ksi |

| Elongation | 18-22% | 18-22% |

| Brinell Hardness (HB) | 170-240 HB | 170-240 HB |

| Rockwell Hardness (HRC) | 52-62 HRC | 52-62 HRC |

| Vickers Hardness (HV) | 160-250 HV | 160-250 HV |

Industries & Applications

| Industry | Specific Applications |

|---|---|

| Construction | Bridges, building facades, structural steel, cladding panels |

| Transportation | Railway cars, shipping containers, highway barriers |

| Art & Architecture | Sculptures, outdoor art installations, architectural features |

| Energy | Transmission towers, wind turbine structures |

| Infrastructure | Utility poles, guardrails, outdoor signage |

| Agriculture | Silos, agricultural storage tanks, barns |

Physical Properties

| Physical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Density | 7.85 g/cm³ | 0.284 lb/in³ |

| Melting Point | 1425-1530°C | 2597-2790°F |

| Thermal Conductivity | 50 W/m·K | 34.5 BTU/h·ft·°F·in |

| Specific Heat Capacity | 0.46 J/g·K | 0.11 BTU/lb·°F |

| Poisson’s Ratio | 0.27-0.30 | 0.27-0.30 |

| Coefficient of Thermal Expansion | 11-13 µm/m·°C | 6.1-7.2 µin/in·°F |

Machining

A606 Heat Treatment Product Options

We offer a range of heat treatment options tailored specifically to optimize the performance of A606 weathering steel. Our heat treatment services include:

- Normalizing A606: This process involves heating the steel to a temperature range of 850°C to 950°C (1562°F to 1742°F), followed by air cooling. It refines the grain structure, improving strength, toughness, and uniformity of the material, making it suitable for high-performance applications.

-

Annealing A606: This process is done by heating the steel to a temperature of about 650°C to 750°C (1202°F to 1382°F) and then allowing it to cool slowly. This treatment reduces internal stresses, making the material easier to form or weld.

Each form is optimized for specific applications, ensuring that S235 Weathering Steel meets precise requirements for durability, machinability, and structural integrity.

A606 Surface Finish Product Options

To meet your project needs, we provide a variety of surface finishing options including:

- Shot Blasting: Cleans the surface by using high-velocity abrasive particles, ensuring a smooth and uniform finish while preparing the steel for further processing or coating.

- Protective Coating: Applies a durable protective layer, such as a clear finish or corrosion-resistant coating, to further enhance the longevity.

- Passivation: Accelerates the development of the protective patina, improving the resistance to environmental corrosion by stabilizing the oxide layer.

- Pickling: A chemical process that removes surface impurities like oxides and scales, ensuring a smooth, clean surface for better patina formation and more consistent corrosion resistance.

Additionally, we specialize in customized surface treatments to meet the specific needs of your project, whether it is a unique finish for an artistic installation or specialized corrosion protection for an industrial application.

A606 Weathering Steel Manufacturer

As a trusted supplier of A606 Weathering Steel, we combine expertise in pricing, product range, quality control, and logistics to deliver reliable solutions:

- Competitive Pricing and Client-Focused Service: We offer cost-effective A606 steel without compromising quality, ensuring responsive support and transparent communication throughout your project.

- Wide Product Range and Customization: Our A606 portfolio includes diverse profiles and dimensions, with custom services like cutting, bending, and size adjustments to meet your exact needs.

- Strict Quality Control and Certification: All A606 products undergo rigorous quality checks and meet industry standards, including certifications like ASTM A606 and ASTM A242, ensuring high reliability.

- Tailored Solutions, Secure Packaging, and Timely Delivery: We provide custom solutions, secure packaging for safe transit, and efficient logistics to ensure timely delivery for your project’s success.

We aim to be your trusted A606 Weathering Steel partner, offering consistent quality and value every step of the way.

Our Service

SteelPRO Group – manufacturer and solution provider for special steel, offering multi-industry application solutions and customised services, 100% quality free, accompanying customers in their growth!

Our Quality Control

- Roundness

- Tolerance

- Microstructure

- Non-Destructive Testing

- Destructive Testing

- Process Control

Service Integration Processing

- Welding

- Metal Fabrication

- CNC Machining

- Lathe

- Forming

Do You Offer Custom Sizes For A606 Weathering Steel?

Absolutely! We offer custom sizes tailored to your specific needs, including adjustments to length, width, and thickness. Our network of trusted suppliers ensures we can meet your exact requirements.

How Can I Ensure The Quality Of A606 Weathering Steel Meets Standards?

We pride ourselves on providing high-quality A606 weathering steel. Each batch is rigorously tested to meet industry standards, and we provide material certificates and test reports to confirm the quality.

Is There A Minimum Order Quantity (MOQ) For A606 Weathering Steel?

There is no strict minimum order quantity, but smaller orders may incur higher shipping or handling costs. We are happy to accommodate both large and small orders, so feel free to inquire about your specific needs, and we’ll provide the best possible solution.

What Is The Typical Lead Time For A606 Weathering Steel Delivery?

The typical lead time depends on the order quantity, customization, and stock availability. For standard orders, we usually deliver within 2 to 4 weeks. If you have an urgent need, let us know, and we’ll work to expedite the process.

What If I Need Technical Support Or Further Assistance With My Order?

Our team is here to help. If you need any technical support, have questions about the steel, or require assistance with your order, feel free to contact us. We offer dedicated support to ensure that your project runs smoothly from start to finish. Whether it’s technical advice or logistical coordination, we’re just a call or email away.

Can I Reorder The Same A606 Weathering Steel Material In The Future?

Absolutely! If you need to reorder the same A606 weathering steel material in the future, just provide us with the order details or reference number, and we can quickly process your repeat order. We maintain a reliable record of past orders to ensure consistency in your material specifications.

CONTACT

CONTACT

Certifications

Other Products

-

-

SteelPRO Group offers FH550 high-strength structural steel plates for shipbuilding....

-

SteelPRO Group offers DH550 high-strength shipbuilding steel plates in stock....

-

SteelPro Group offers FH36 high-strength steel for shipbuilding. It has...