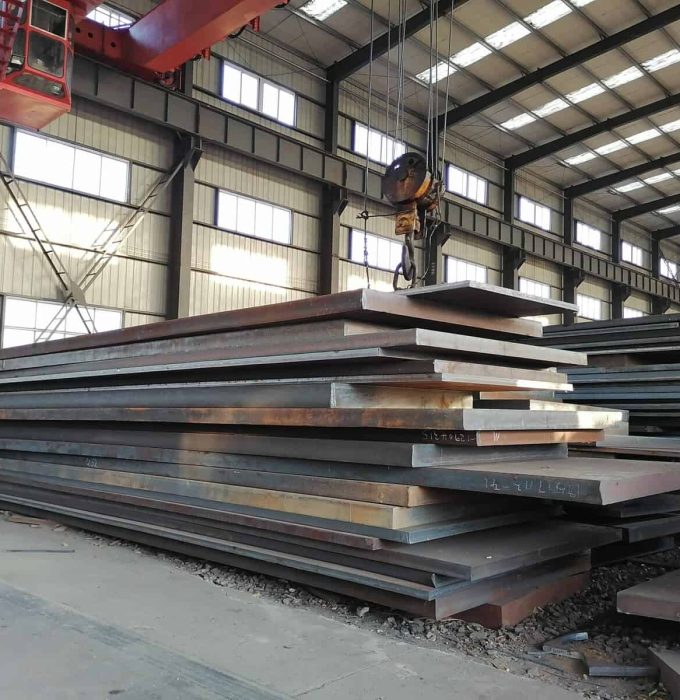

ALLOY STEEL

Superior Strength. Corrosion Resistant. Enhance Your Projects with Alloy Steel.

Introduction to Alloy Steel

Benefits of Alloy Steel

Alloy steel offers several significant advantages:

- Superior Strength: Enhanced by alloying elements, providing higher strength compared to carbon steel.

- Corrosion Resistance: Alloying elements like chromium and nickel improve corrosion resistance, making it suitable for harsh environments.

- Wear Resistance: Elements such as vanadium and molybdenum increase wear resistance, extending the lifespan of components.

- Heat Resistance: Maintains strength and hardness at high temperatures, ideal for high-temperature applications.

- Hardenability: Alloying elements improve hardenability, allowing for deeper hardening during heat treatment.

- Versatility: Available in a wide range of grades, making it suitable for diverse applications in various industries.

Types of Alloy Steel

- Low-Alloy Steel (Alloying Element Content <5%)

- Boron Steel: Hard, wear-resistant, used in automotive and agricultural parts.

- AISI 4140 and 4340: High strength and toughness for gears and aerospace.

- AISI 6150, 8620, and 4130: Used for springs, crankshafts, and motorsports.

- Medium-Alloy Steel (Alloying Element Content 5%-10%)

- 300M: High-strength, low-alloy steel for aircraft landing gear.

- Silicon Steel: For improved electrical performance in transformers and motors.

- Tool Steel: High hardness and wear resistance, used in cutting and drilling tools.

- High-Alloy Steel (Alloying Element Content >10%)

- H13 Tool Steel: Tough, hard, heat-resistant, used for dies, molds, and tooling.

- AISI 316 Stainless : Corrosion-resistant, high-temp, for marine and chemical use.

- Maraging Steel: Ultra-strong and tough, for aerospace and high-performance.

Industries & Applications

Some common industries and applications include:

Automotive Industry

Aerospace Industry

Construction Industry

Manufacturing

Energy Sector

Tool and Die Making

Shipbuilding

Railway Industry

Dimensions & Properties

| AISI 4340 | AISI 8620 | AISI 6150 | |

|---|---|---|---|

| Yield Strength | 745 MPa (108 ksi) | 620 MPa (90 ksi) | 760 MPa (110 ksi) |

| Tensile Strength | 1100 MPa (160 ksi) | 930 MPa (135 ksi) | 1080 MPa (157 ksi) |

| Material Standard | ASTM A29 / A29M | ASTM A29 / A29M | ASTM A29 / A29M |

| Vickers Hardness | Approximately 248-302 HV | Approximately 156-207 HV | Approximately 248-302 HV |

Alloy Steel When & Where You Need It

Here, you get more than just quality steel. With multiple facilities across the country capable of providing high-strength steels, we can also work with you to manage your inventory, ensuring you get product when and where you need it to keep your production running.

Explore Our Available Steel Products & Grades

Our knowledge and experience give nearly 100% accurate delivery of alloy steel products processed and packaged to your exact specifications.

Is Alloy Steel Rust Proof?

No, alloy steel is not entirely rust-proof, but it can be more corrosion-resistant than plain carbon steel depending on the alloying elements used, such as chromium and nickel.

What are the Benefits of Alloy Steel?

Alloy steel offers enhanced strength, toughness, hardness, and corrosion resistance compared to plain carbon steel. It can also be tailored for specific properties through various alloying elements.

Does Alloy Tarnish Easily?

The tendency of an alloy to tarnish depends on its composition. Some alloys, like stainless steel, are resistant to tarnishing, while others may tarnish more easily.

Is Alloy Steel Safe for Food?

Yes, certain types of alloy steel, particularly stainless steel, are safe for food contact as they are resistant to corrosion and do not leach harmful substances.

What's Better, Metal or Alloy Steel?

“Better” depends on the application. Alloy steel generally offers superior mechanical properties and corrosion resistance compared to plain metals, making it more suitable for demanding applications.