347 | 347H Stainless Steel Bar

347 | 347H Stainless Steel Bar

SteelPRO Group is a leading manufacturer and supplier of 347/347H Stainless Steel Bar in China. We provide:

1.4550 Stainless Steel Bar, 1.4961 Stainless Steel Bar, S34700 Stainless Steel Bar, S34709 Stainless Steel Bar, AISI 347 Stainless Steel Bar, AISI 347H Stainless Steel Bar, 347 /347H Stainless Steel Round Bar, 347/347H Stainless Steel Hex Bar, 347/347H Stainless Steel Square Bar, 347/347H Stainless Steel Flat Bar, 347/347H Stainless Steel Precision Ground Bar, etc. We offer a range of processing services for 347 and 347H stainless steel bars, including custom cutting, precision machining, surface treatments, heat treatment, welding support, and quality testing.

| Standard | ASTM A276, ASTM A479/A479M, ASTM A484/A484M, ASME SA276, ASME SA479, EN 10088-3, JIS G4303 |

|---|---|

| Grade | X6CrNiNb18-10 (1.4550)/19 9 Nb, Z6CNNb18-10, 347S31, X7CrNiNb18-10 (1.4912), S34709, SUS347H |

| Length | 1 – 6 meters (3.28 – 19.69 feet) or customized |

| Diameter | 6 – 250 mm (0.24 – 9.84 inches) or customized |

| Shape | Round Bar, Square Bar, Hexagonal Bar, Flat Bar, Rectangular Bar, Angle Bar, Channel Bar, T-Bar or customized |

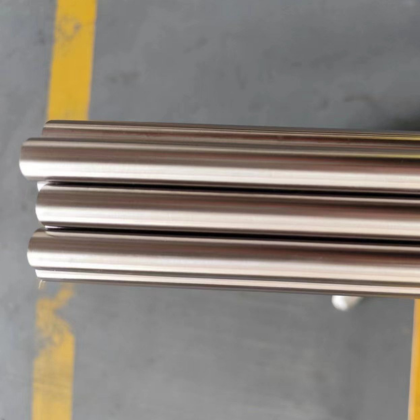

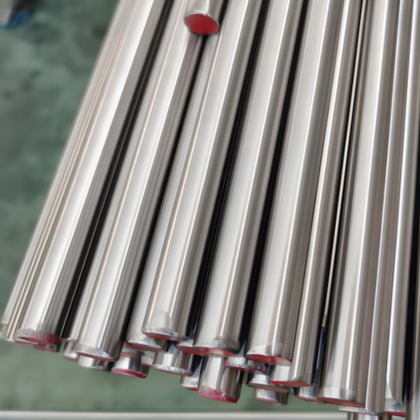

| Surface Finish | Bright, Peeled, Brushed, Polished, Black, or Customized |

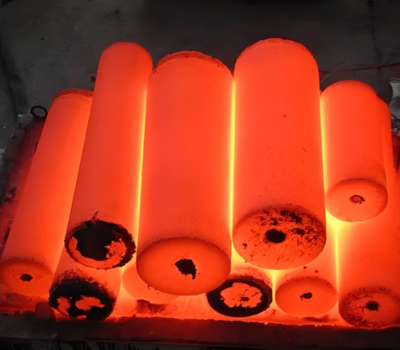

| Technique | Cold Drawn, Hot Rolled, Cold Rolled |

| Form | 347 | 347H Stainless Steel Rod, 347/347H Stainless Steel Tube, 347/347H Stainless Steel Pipe,, Hot Rolled Bars, Cold Drawn Bars, Annealed Bars, Polished Bars, Peeled Bars, Ground Bars, Custom Cut Bars |

347 | 347H Stainless Steel Bar

347 | 347H Stainless Steel Bar

Business Terms

Business Terms

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: | Korea, United States, Russian Federation, Brazil, United Kingdom, Canada, Australia, India, Germany, Turkey |

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Nitrogen (N) | Niobium (Nb) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|---|

| 347 | 0.08 max | 2.00 max | 0.75 max | 0.045 max | 0.030 max | 17.00-19.00 | 9.00-13.00 | 0.10 max | 10xC min; 1.0 max | Balance |

| 347H | 0.04-0.10 | 2.00 max | 0.75 max | 0.045 max | 0.030 max | 17.00-19.00 | 9.00-13.00 | 0.10 max | 10xC min; 1.0 max | Balance |

Mechanical Properties

Mechanical Properties

| Property | 347 Stainless Steel | 347H Stainless Steel |

|---|---|---|

| Tensile Strength | 515 MPa (74,694 psi) min | 515 MPa (74,694 psi) min |

| Yield Strength | 205 MPa (29,732 psi) min | 205 MPa (29,732 psi) min |

| Elongation at Break | 40% min | 35% min |

| Hardness (Rockwell B) | 95 max | 95 max |

| Hardness (Brinell) | 201 max | 201 max |

| Hardness (Vickers) | 220 max | 220 max |

| Modulus of Elasticity | 193-200 GPa (28,000-29,000 ksi) | 193-200 GPa (28,000-29,000 ksi) |

Heat Treatment

Heat Treatment

- Annealing

- Temperature: 1010°C – 1120°C (1850°F – 2050°F)

- Process: Heat and rapidly cool. Relieves stresses, enhances ductility and toughness, and restores austenitic structure.

- Solution Annealing

-

- Temperature: 1038°C – 1149°C (1900°F – 2100°F)

- Process: Heat to dissolve carbides and precipitates, then rapidly cool. Improves corrosion resistance and ensures a uniform austenitic structure.

-

- Normalizing, Quenching, and Tempering: These processes are not used for 347 and 347H because these austenitic steels already possess a stable structure and do not require these treatments.

Characteristic

Characteristic

- 347 Stainless Steel Bar

- Excellent intergranular corrosion resistance.

- Good high-temperature strength and oxidation resistance.

- Niobium-stabilized for enhanced resistance to sensitization.

- Superior weldability and formability.

- Suitable for intermittent heating up to 870°C (1600°F).

- Maintains strength and toughness at low temperatures.

- 347H Stainless Steel Bar

- Higher carbon content for improved high-temperature strength and creep resistance.

- Excellent intergranular corrosion resistance, even after prolonged high-temperature exposure.

- Niobium-stabilized to prevent chromium carbide precipitation.

- Good weldability and formability, similar to 347.

- Suitable for prolonged exposure up to 900°C (1650°F).

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

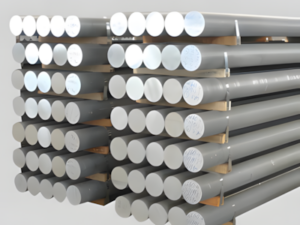

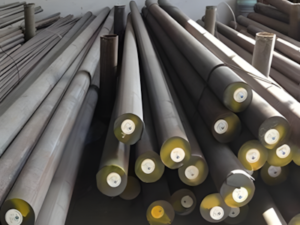

Surface Finish

Surface Finish

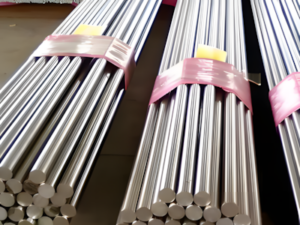

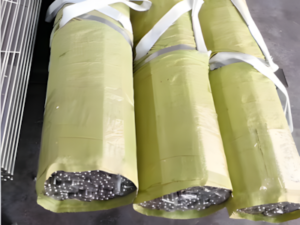

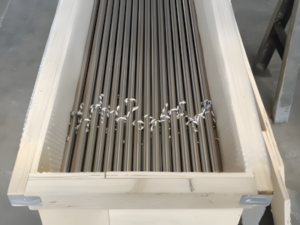

Packing

Packing

We provide high-quality packaging services for 347/347H stainless steel bars.

- Standard Packaging: Bars are bundled and wrapped in waterproof, corrosion-resistant materials, then strapped with steel bands for secure transport.

- Wooden Crates or Pallets: For added protection, especially in international shipping, bars may be placed in wooden crates or on pallets.

- Custom Packaging: Custom packaging options are available, including specific crate sizes, special coatings, and additional protective materials.

- After-Sales Service: We provide after-sales support for any packaging concerns, including damage claims and custom packaging requests, ensuring customer satisfaction.

Why Choose Us

Why Choose Us

At SteelPRO Group, we deliver top-quality 347 and 347H Stainless Steel Bars. Here’s what sets us apart:

- High-Quality Products: 347 and 347H Stainless Steel Bars meet top industry standards.

- Extensive Customization: Available in various shapes, sizes, and finishes.

- Advanced Manufacturing: Uses modern equipment for optimal properties and finish.

- Rigorous Quality Control: Stringent inspections ensure compliance with specifications.

- Competitive Pricing and Fast Delivery: Affordable pricing with timely delivery.

- Expert Support: Experienced team provides technical advice and support.