410 Stainless Steel Rod | Bar

410 Stainless Steel Rod | Bar

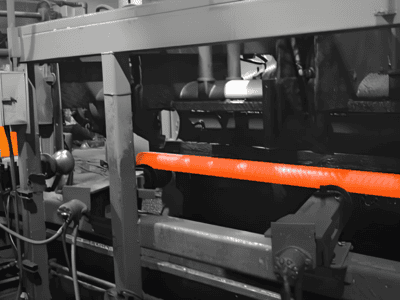

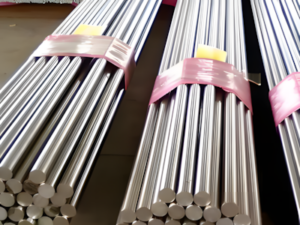

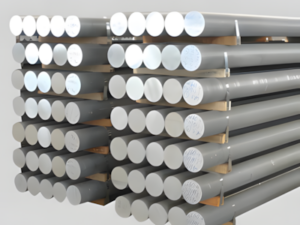

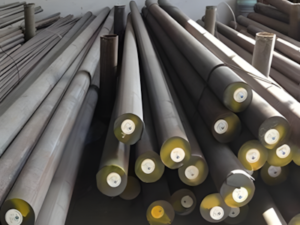

We are a 410 stainless steel rod and bar supplier. We offer various types of products, including UNS S41000 rods and 1.4006 stainless steel bars. Our product range includes round bars, square bars, hexagonal bars, and flat bars. Our manufacturing processes include hot rolled, cold drawn, precision ground, and centerless ground methods. We also provide custom product services.

| Standard | ASTM A240, ASTM A276, ASTM A479 |

|---|---|

| Grade | 1.4006, 410S21, X12Cr13 |

| Length | 3 m (10 ft) to 7.5 m (25 ft), Customized |

| Diameter | 6 mm (0.24 in) to 150 mm (6 in), Customized |

| Surface Finish | BA, MP, Passivation, Pickling, Polishing, SB |

| Technique | Cold Drawing, Forging, Heat Treatment, Hot Rolling |

| Form | Cold Drawn Bar, Flat Bar, Hexagonal Rod, Hot Rolled Bars, Round Bar, Round Rod, Square Bar, Square Rod |

410 Stainless Steel Rod | Bar

410 Stainless Steel Rod | Bar

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Korea, Russian Federation, United Kingdom, India, Brazil, etc.

|

Chemical Compositions

Chemical Compositions

| Element | C | Mn | Si | Cr | Ni | P | S | Fe |

|---|---|---|---|---|---|---|---|---|

| Composition Range (%) | 0.08 – 0.15 | 1.00 max | 1.00 max | 11.50 – 13.50 | 0.75 max | 0.04 max | 0.03 max | Balance |

Mechanical Properties

Mechanical Properties

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 480 – 680 MPa | 70 – 99 ksi |

| Yield Strength | 275 – 450 MPa | 40 – 65 ksi |

| Brinell Hardness (HB) | 170 – 240 HB | 170 – 240 HB |

| Rockwell Hardness (HRC) | 20 – 35 HRC | 20 – 35 HRC |

| Vickers Hardness (HV) | 180 – 255 HV | 180 – 255 HV |

| Elongation | 20% – 30% | 20% – 30% |

| Elastic Modulus | 200 GPa | 29 x 10³ ksi |

Heat Treatment

Heat Treatment

-

Normalizing

-

Heat to 870°C to 900°C (1600°F to 1650°F) and hold at temperature. Then, air cool.

-

Refines grain structure and improves mechanical properties.

-

-

Annealing

-

Heat to 815°C to 900°C (1500°F to 1650°F) and hold at temperature. Then, cool slowly in the furnace.

-

Softens the material, improves machinability, and prepares it for further processing.

-

-

Hardening (Quenching)

-

Heat to 925°C to 1010°C (1700°F to 1850°F) and hold at temperature. Then, rapidly cool by water quenching or oil quenching.

-

Increases hardness and strength but can reduce ductility.

-

-

Tempering

-

Heat to 200°C to 600°C (390°F to 1110°F) depending on the required hardness and hold at temperature. Then, air cool.

-

Reduces brittleness, improves toughness, and restores some ductility after hardening.

-

-

Stress Relieving

-

Heat to 200°C to 400°C (390°F to 750°F) and hold to reduce residual stresses from cold working or welding. Cool slowly in the air.

-

Reduces residual stresses, improves dimensional stability, and enhances mechanical properties.

-

Characteristic

Characteristic

- High Strength: 410 stainless steel plate and pipe have excellent tensile strength, making them suitable for heavy-duty applications.

- Moderate Corrosion Resistance: These products resist corrosion in mild environments.

- Magnetic Properties: The products are magnetic in both annealed and hardened conditions.

- Heat Treatable: The material can be hardened through heat treatment, enhancing its hardness and strength.

- Application Versatility: Suitable for diverse uses, including pipelines and structural components.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

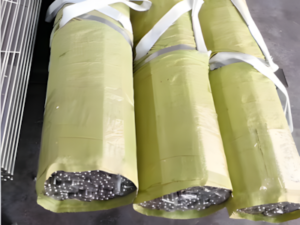

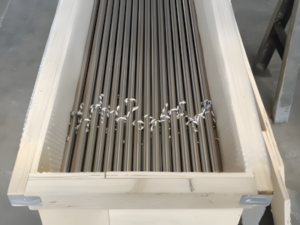

Packing

Packing

To deliver your 410 stainless steel rod and bar in perfect condition, our packaging solutions adhere to international shipping and safety standards.

- Prevent deformation: Use high-quality wooden crates, steel straps, and sturdy pallets to secure your rods and bars from deformation and damage during transportation.

- Prevent Bending: Use strong supports and bracing within the wooden crates to prevent bending or warping of the rods and bars during transit.

- Secure Bundling: Tightly bundle pipes to prevent movement and damage during transit, ensuring your products arrive in excellent condition.

- Customized Packaging: Our packaging solutions are tailored to fit the specific dimensions and quantities of your order, ensuring maximum protection and ease of handling.

- Proper Labeling: Each package is clearly labeled with detailed information, including products specifications and handling instructions, for easy identification and smooth logistics.

When you choose us for your 410 stainless steel rod and bar needs, you can trust that your products will be delivered securely and ready for immediate use.

Why Choose Us

Why Choose Us

At SteelPRO Group, we are committed to delivering top-quality stainless steel products that meet industry standards. With years of experience in the stainless steel industry, we understand the specific needs of our clients and provide tailored solutions.

Quality Control: Our products undergo strict quality control processes to ensure they meet the highest standards of reliability and durability.

Competitive Pricing: We offer high-quality products at competitive prices, ensuring you get the best value for your investment.

Customer Support: Our knowledgeable team provides expert advice and assistance, helping you find the right product for your specific requirements.