15-5PH Stainless Steel Bar, Plate & Sheet

15-5PH Stainless Steel Bar, Plate & Sheet

SteelPRO Group is 15-5PH stainless steel supplier and manufacturer of steel products, specializing in high-quality materials and services. We provide customization, cutting, surface treatment, machining, material testing and other services.

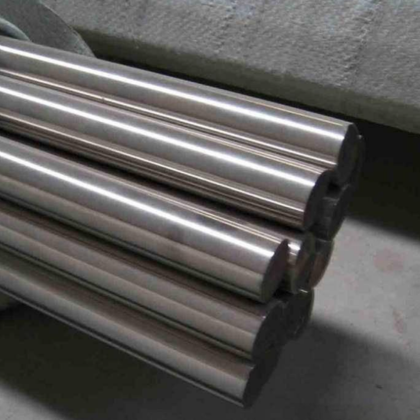

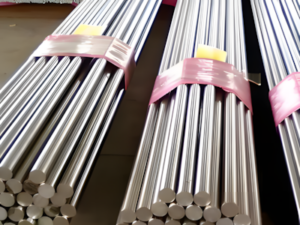

Our products: 15-5PH round bar, 15-5PH flat bar, 15-5PH square bar, 15-5PH plate, 15-5PH sheet, 1.4545 cold rolled plate, 15-5PH hot rolled sheet, S15500 rectangular bar, 15-5PH cold drawn bar, 15-5PH precision ground bar, 15-5PH forged bar, 15-5PH polished plate, 15-5PH tempered sheet, etc.

| Standard | AMS 5659, AMS 5823, AMS 5862, ASTM A564 / A564M, ASTM A693 |

|---|---|

| Grade | 0Cr15Ni5Cu4Nb, 1.4545, S15500 |

| Length | 1000 mm-6000 mm (39.37-236.22 in), Customized |

| Diameter | Bar: 6 mm-300 mm (0.24-12 in), Customized |

| Thinckness | Customized, Plate: 6 mm-100 mm (0.24-3.94 in), Sheet: 0.5 mm-6 mm (0.02-0.24 in) |

| Full Width | Customized, Sheet & Plate: 1000 mm-2000 mm (39.37-78.74 in) |

| Surface Finish | 2B, 2D, BA, Coated, etc., Ground, Mill, No.1, No.4, Peeled, Polished, Turned |

| Form | 15-5PH Forged bar, 15-5PH plate, 15-5PH Polished plate, 15-5PH sheet, 15-5PH Tempered sheet, Coil, Cold Drawn Bar, Cold-Rolled Plate, etc., Flat Bar, Hot-rolled sheet, Rectangular bar, Rod, Round Bar, Square Bar, Strip |

15-5PH Stainless Steel Bar, Plate & Sheet

15-5PH Stainless Steel Bar, Plate & Sheet

- 15-5PH bar is a precipitation hardening steel known for its high strength, corrosion resistance and toughness. Its key features include excellent mechanical properties, good weldability, heat treatability and reliable pressure performance. Common applications include aircraft accessories, shafts, gears and high-performance fasteners.

- 15-5PH plate is a durable, corrosion-resistant material with high tensile strength and good toughness. This material is often used in aerospace structural components, pressure vessels and large industrial machinery parts that need to withstand harsh conditions and heavy loads.

- 15-5PH sheet is a versatile material with strong corrosion resistance and easy processing. It has good formability and excellent performance after heat treatment. This makes it suitable for precision parts, springs and fasteners in aerospace panels, medical devices and chemical processing equipment.

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, France, Japan, Germany, Italy, Spain, United Kingdom, Taiwan, Turkey, Korea, Brazil, Austria, Netherlands, Mexico, India, Poland, Vietnam, Russian Federation, etc.

|

Chemical Compositions

Chemical Compositions

| Chromium (Cr) | Nickel (Ni) | Copper (Cu) | Manganese (Mn) | Silicon (Si) | Carbon (C) | Phosphorus (P) | Sulfur (S) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| 14.0 – 15.5 | 3.5 – 5.5 | 2.5 – 4.5 | 1.0 max | 1.0 max | 0.07 max | 0.04 max | 0.03 max | 0.10 max |

Mechanical Properties

Mechanical Properties

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 1000-1170 MPa | 145-170 ksi |

| Yield Strength | ≥ 1000 MPa | ≥ 145 ksi |

| Vickers Hardness | 360 HV (typical) | 360 HV (typical) |

| Brinell Hardness | 350 HB (typical) | 350 HB (typical) |

| Rockwell Hardness | 35 HRC (typical) | 35 HRC (typical) |

| Elongation | ≥ 10% | ≥ 10% |

| Elastic Modulus | 200 GPa | 29.0 x 10³ ksi |

Heat Treatment

Heat Treatment

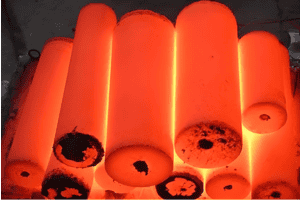

- Solution Annealing: Applicable to 15-5PH Bar, Plate and Sheet. Heat the material to 1038°C (1900°F), hold for 1 hour, then air cool. This process is usually followed by precipitation hardening.

- Precipitation Hardening: Applicable to 15-5PH Bar, Plate and Sheet.

- H900: 482°C (900°F), hold for 1 hour, then air cool.

- H925: 496°C (925°F), hold for 4 hours, then air cool.

- H1025: 552°C (1025°F) for 4 hours, then air cool.

- H1075: 579°C (1075°F) for 4 hours, then air cool.

- H1150: 621°C (1150°F) for 4 hours, then air cool.

- Stress Relief: Applicable to 15-5PH Plate and Sheet, not usually for bars. Heat to 677°C (1250°F) for 1 hour and air cool. If slight cold working or machining is required after aging, this is usually done.

- Quenching, Tempering & Normalizing: Not applicable to 15-5PH Bar, Sheet and Plate.

- Carburizing, Nitriding: Not necessary for 15-5PH Bar, Sheet and Plate.

Characteristic

Characteristic

- 15-5PH Bars are favored for high-strength, load-bearing parts that require toughness and machinability. They offer excellent strength and toughness, along with good machinability in the annealed condition, making them ideal for heavy-duty components.

- 15-5PH Plates are chosen for structural and precision applications, offering uniform strength and good weldability. Their consistent mechanical properties and high fatigue resistance make them suitable for critical structural components.

- 15-5PH Sheets are used in lightweight, formable applications where strength, corrosion resistance, and surface finish are important. They provide good formability and surface quality, ideal for applications in aerospace and automotive industries where weight and appearance are crucial.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

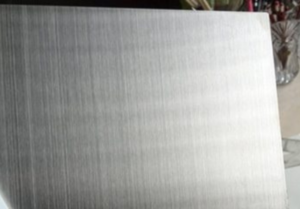

2B Surface

2D Surface

BA Surface

6K Surface

8K Surface

HL Surface

NO.1 Surface

NO.4 Surface

Embossed Surface

Packing

Packing

At SteelPRO Group, we follow strict packaging standards to protect your 15-5PH stainless steel products from damage, corrosion, and contamination. Here’s how we package bars, plates, and sheets:

- Bars:

- Protective Packaging: Each pole is individually wrapped in corrosion-resistant paper or plastic to prevent surface damage and rust.

- Wooden Boxes or Steel Straps: The poles are strapped and secured with durable steel straps or placed in custom wooden boxes to prevent movement during shipping.

- Custom Packaging: We offer additional custom packaging solutions based on your project needs, including specific labels and barcodes for easy identification.

- Plates and Sheets:

- PVC or Paper Barriers: Each board is laminated with PVC film or paper to prevent scratches and surface damage during handling.

- Palletization for Stability: Boards are stacked on heavy-duty wooden pallets and secured with protective edge guards and steel straps to ensure stability during shipping.

- Waterproofing: For outdoor or long-distance shipping, boards are covered with waterproof material to protect against moisture and wind and sun.

- Custom Protection: For sensitive or high-value applications, we offer custom packaging solutions including vacuum seals or protective films to protect materials from the environment.

Why Choose Us

Why Choose Us

SteelPRO Group is committed to being your reliable source for high-quality stainless steel products, with a strong emphasis on delivering excellence and exceptional customer care.

- Quality Assurance: We partner with leading mills and implement rigorous quality control measures to ensure each batch meets the highest standards and fulfills your specific requirements.

- Diverse Product Range: Our stock includes plates, tubes, bars, coils, and more, available in standard sizes or customized to meet the needs of different industries.

- Tailored Solutions: Our team works closely with you to provide expert guidance and create bespoke products designed for your project.

- On-Time Delivery: With a robust supply chain and dependable partnerships, we guarantee the timely arrival of your orders.

- Outstanding Customer Support: Our dedicated support team is available to offer technical advice, assist with logistics, and provide post-purchase support whenever needed.