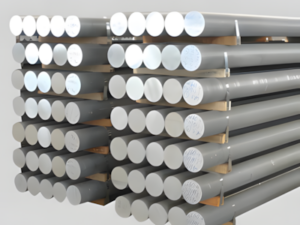

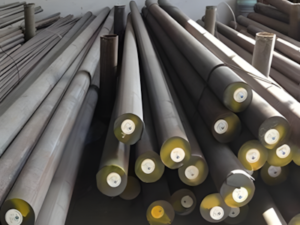

316L Stainless Steel Bar

316L Stainless Steel Bar

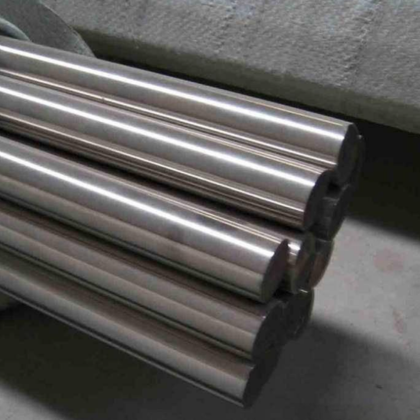

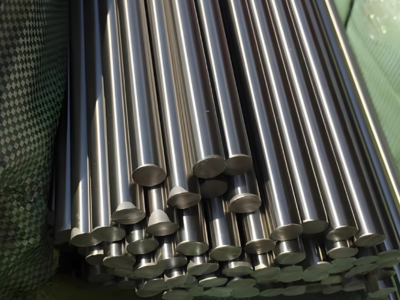

SteelPro Group is a steel supplier and manufacturer, we produce different types of steel bars including 316L Bar. We offer customization services and have a range of surface finish options.

Our products: 316L Round Bar, 316L Flat Bar, 1.4404 Bar & Rod, Square Bar, Hexagonal Bar, SUS316L Cold Drawn Bar, Cold-Rooled Bar, Hot- Rolled Bar, Bright Bar, Angle Bar, Channel Bar, T-Bar, Bars for Fabrication or DIY.

| Standard | ASTM A276, ASTM A479/A479M, ASTM A484/A484M, ISO 683-13 |

|---|---|

| Grade | 00Cr17Ni14Mo2, 0Cr18Ni12Mo2Ti, 1.4404, SUS316L, X2CrNiMo17-12-2 |

| Length | Customized |

| Diameter | 3 mm to 500 mm (0.12-19.7 in), Customized |

| Shape | Angle Bar, Channel Bar, Customized, Flat, Hexagonal, Rectangular, Round, Square, T-Bar |

| Surface Finish | 2B, BA, Black, Brushed, Customized, Peeled, Polished |

| Technique | Cold Drawn, Cold Rolled, Hot Rolled |

| Form | Bar in various shapes, Cold-Finished Bars, Customized, Flat Bar, Forged Bars, Hollow Bar, Hot-Rolled Bar, Rod, Round Bar, Threaded Bar |

316L Stainless Steel Bar

316L Stainless Steel Bar

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Canada, Philippines, Australia, India, United Kingdom, Korea, Malaysia, Russian Federation, United Arab Emirates, Germany, Singapore, Brazil, Hong Kong, Indonesia, France, New Zealand, Norway, Pakistan, South Africa, Spain, Egypt, Italy, Mexico, Taiwan, Vietnam, Romania, etc.

|

Chemical Compositions

Chemical Compositions

| Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| ≤ 0.03 | ≤ 0.75 | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | ≤ 0.10 |

Mechanical Properties

Mechanical Properties

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 485 – 620 MPa | 70 – 90 ksi |

| Yield Strength | 170 – 310 MPa | 25 – 45 ksi |

| Vickers Hardness | 150 – 200 HV | 150 – 200 HV |

| Brinell Hardness | 146 – 217 HB | 146 – 217 HB |

| Rockwell Hardness | B80 – C20 | B80 – C20 |

| Elongation | 40% – 50% | 40% – 50% |

| Elastic Modulus | 193 – 200 GPa | 28 – 29 x 10^6 psi |

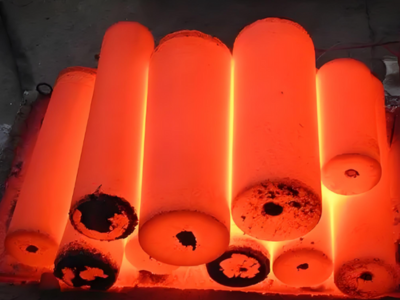

Heat Treatment

Heat Treatment

- Annealing: Heating the bar to a temperature range of 1010-1120°C (1850-2050°F) followed by rapid cooling (usually in water or air).

- Stress Relief: Stress relief is not applicable to 316L due to its excellent stress tolerance.

- Heat Treatment Hardening: 316L stainless steel cannot be hardened by conventional heat treatment methods such as quenching and tempering because it is an austenitic stainless steel.

Characteristic

Characteristic

- Excellent Corrosion Resistance: Ideal for marine and harsh environments.

- Low Carbon Content: Reduces carbide precipitation during welding.

- Good Formability and Weldability: Easy to shape and weld.

- High Ductility and Strength: Strong and flexible under stress.

- Non-Magnetic (Annealed): Remains non-magnetic after annealing.

- Heat Resistant: Performs well at high temperatures.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

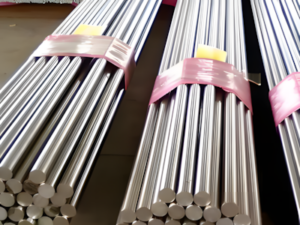

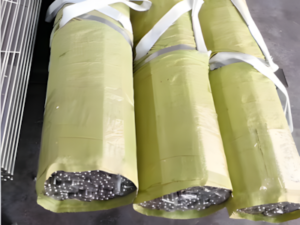

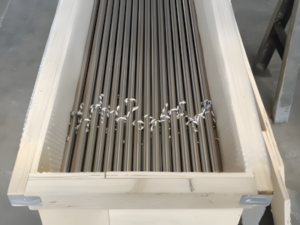

Packing

Packing

We use proper packaging to ensure the integrity of our 316L stainless steel bars is maintained during shipping and handling.

- Protective Packaging: Each 316L stainless steel bar is carefully packed using moisture-proof materials to prevent corrosion and damage.

- Multiple Options: We offer a variety of packaging solutions, including wooden crates, secure bales, and custom packaging to meet your specific needs.

- Clear Labeling: Each package is clearly labeled with detailed product information, including material grade, size, and batch number for easy identification and traceability.

- Safe Shipping: Our robust packaging methods ensure your product arrives safely and is immediately available for use in your application.

Why Choose Us

Why Choose Us

Partner with us for consistent quality, technical expertise, and commitment to your success.

- Premium Quality: Our 316L stainless steel rods are manufactured to the highest standards, ensuring excellent corrosion resistance, strength, and durability.

- Advanced Manufacturing: We use cutting-edge technology and strict quality control to meet the most demanding industry specifications.

- Competitive Pricing: We offer cost-effective solutions without compromising quality, providing excellent value for your investment.

- Reliable Delivery: We guarantee on-time delivery, ensuring your project stays on schedule.

- Expert Support: Our experienced team provides personalized service and technical expertise to help you select the right product for your specific needs.

- Custom Solutions: We customize our products to your unique project requirements, ensuring you get the best product for your application.