410s Stainless Steel Bar | Sheet | Plate | Coil

410s Stainless Steel Bar | Sheet | Plate | Coil

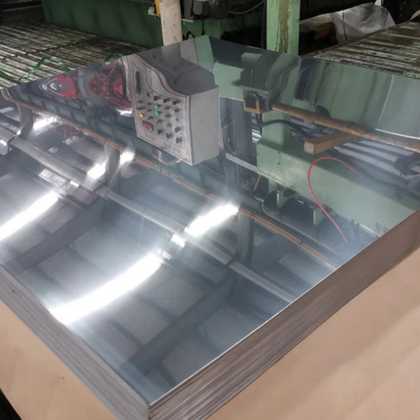

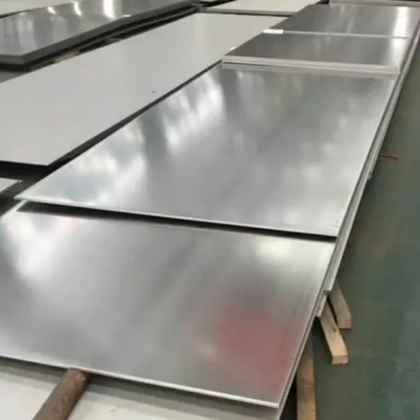

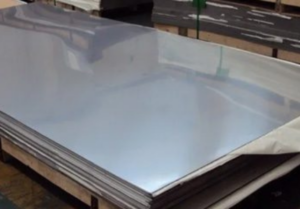

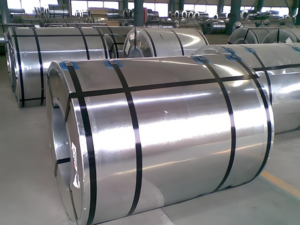

We are a 410S stainless steel bar, sheet, plate, and coil supplier. We offer various products, including:

Round, square, and hexagonal bars; cold-rolled and hot-rolled sheets; hot-rolled, cold-rolled, and perforated plates; as well as hot-rolled and cold-rolled coils.

Our processing methods include cutting, shearing, slitting, bending, polishing, and welding. We also provide custom product services to meet specific customer requirements.

| Standard | ASTM A240, ASTM A276, EN 1.4000, UNS S41008 |

|---|---|

| Grade | 0Cr13, SUS410S, X6Cr13 |

| Length | Bar: 3 m (10 ft) to 6 m (20 ft), Customized, Plates: 1 m (3.3 ft) to 6 m (20 ft), Sheets: 1 m (3.3 ft) to 3 m |

| Width | Coil: 1 m (39.4 in) to 1.5 m (59.1 in), Customized, Plates: 1 m (39.4 in) to 3 m (118 in), Sheets: 1 m (39.4 in) to 2 m (78.7 in) |

| Diameter | Bar: 6 mm (0.25 in) to 150 mm (6 in), Customized |

| Thickness | Coils: 1 mm (0.04 in) to 6 mm (0.25 in), Customized, Plates: 5 mm (0.2 in) to 50 mm (2 in), Sheets: 1 mm (0.04 in) to 6 mm (0.25 in) |

| Surface Finish | 2B, Hot Rolled, No. 1, NO. 4, Passivation, Pickling, Polished, SB |

| Technique | Annealing, CR, HR, Tempering |

| Form | Cold Rolled Sheet, CRC, Hot Rolled Plate and Sheet, HRC, Mill Edge Coils, Rod, Round Bar, Square Bar, True Bar |

410s Stainless Steel Bar | Sheet | Plate | Coil

410s Stainless Steel Bar | Sheet | Plate | Coil

- 410S Bar: Suitable for applications requiring high strength and durability, such as in the construction of structural components and industrial machinery.

- 410S Sheet: Ideal for precision fabrication in automotive and construction sectors, where the material’s formability and dimensional stability are essential.

- 410S Plate: Best suited for use in demanding industrial applications, including the manufacturing of pressure vessels and heavy-duty machinery.

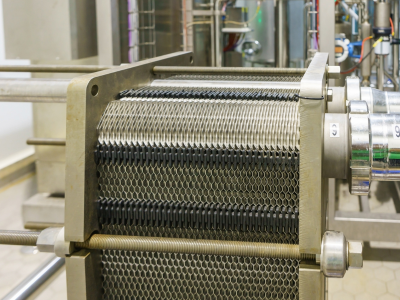

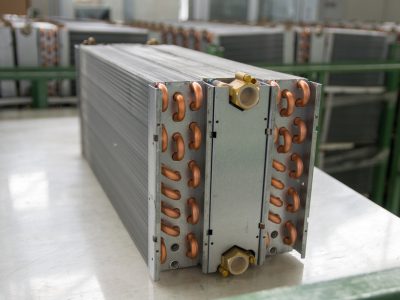

- 410S Coil: Well-suited for applications in automotive exhaust systems and heat exchangers, where its ability to maintain performance at elevated temperatures is crucial.

Business Term

Business Term

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, India, Germany, Poland, Japan, Russian Federation, etc.

|

Chemical Compositions

Chemical Compositions

| Element | C | Mn | P | S | Si | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| Composition | 0.08 max | 1.00 max | 0.040 max | 0.030 max | 1.00 max | 11.50-13.50 | 0.60 max | Balance |

Mechanical Properties

Mechanical Properties

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 450 – 655 MPa | 70 – 95 ksi |

| Yield Strength | 275 – 450 MPa | 40 – 65 ksi |

| Brinell Hardness (HB) | 160 – 200 HB | 160 – 200 HB |

| Rockwell Hardness (HRC) | 15 – 25 HRC | 15 – 25 HRC |

| Vickers Hardness (HV) | 170 – 220 HV | 170 – 220 HV |

| Elongation | 20 – 30% | 20 – 30% |

| Elastic Modulus | 200 GPa | 29,000 ksi |

Heat Treatment

Heat Treatment

- Normalizing

- Not applicable for 410S stainless steel.

- Annealing

- Heated to a temperature between 815°C and 900°C (1500°F to 1650°F) and then slowly cooled in air. Typically performed to soften the material and improve ductility.

- Used for both bar and sheet products.

- Solution Annealing

- Heated to a temperature between 1065°C and 1120°C (1950°F to 2050°F) and then rapidly cooled by quenching to restore or improve corrosion resistance.

- Primarily used for sheet and coil products.

- Quenching

- After solution annealing rapidly cooling the material, typically in water or air to preserve a ductile and corrosion-resistant microstructure.

- Mainly used for sheet and coil products, occasionally for bars if needed.

- Stress Relieving

- Heated to a temperature between 600°C and 750°C (1110°F to 1380°F) and then slowly cooled. It is used to reduce residual stresses from previous processing.

- Use for all forms—bars, sheets, and coils.

Characteristic

Characteristic

Corrosion-Resistant: Performs well in mild corrosive environments and atmospheric conditions.

Heat-Resistant: Remains stable and resists oxidation at elevated temperatures up to 700°C.

Magnetic: Displays magnetic properties due to its ferritic microstructure.

Good Heat Transfer: Effectively conducts heat, making it suitable for thermal applications.

Formable: Can be shaped and formed without losing its structural integrity.

Highly Weldable: Easily joins without the risk of cracking or hardening during welding.

Durable: Offers reliable mechanical strength for structural uses.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

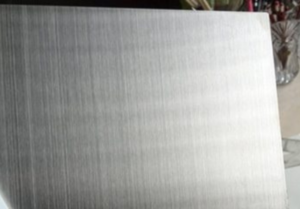

Surface Finish

Surface Finish

2B Surface

2D Surface

BA Surface

6K Surface

8K Surface

HL Surface

NO.1 Surface

NO.4 Surface

Embossed Surface

Packing

Packing

To deliver your 410s stainless steel bar, sheet, plate, and coil in perfect condition, our packaging solutions adhere to international shipping and safety standards.

- Prevent deformation: Use high-quality wooden crates, steel straps, and sturdy pallets to secure your products from deformation and damage during transportation.

- Secure Bundling: Tightly bundle pipes to prevent movement and damage during transit, ensuring your products arrive in excellent condition.

- Customized Packaging: Our packaging solutions are tailored to fit the specific dimensions and quantities of your order, ensuring maximum protection and ease of handling.

- Proper Labeling: Each package is clearly labeled with detailed information, including product specifications and handling instructions, for easy identification and smooth logistics.

When you choose us for your 410s stainless steel needs, you can trust that your products will be delivered securely and ready for immediate use.

Why Choose Us

Why Choose Us

At SteelPRO Group, we are committed to delivering top-quality stainless steel products that meet industry standards. With years of experience in the stainless steel industry, we understand the specific needs of our clients and provide tailored solutions.

Quality Control: Our products undergo strict quality control processes to ensure they meet the highest standards of reliability and durability.

Competitive Pricing: We offer high-quality products at competitive prices, ensuring you get the best value for your investment.

Customer Support: Our knowledgeable team provides expert advice and assistance, helping you find the right product for your specific requirements.