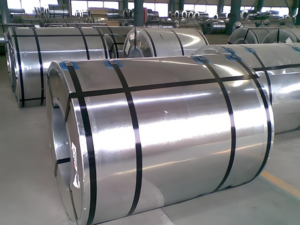

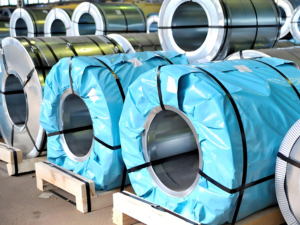

SteelPRO Group is a leading manufacturer and supplier of 310/310S Stainless Steel Coils and Strips in China. We provide:

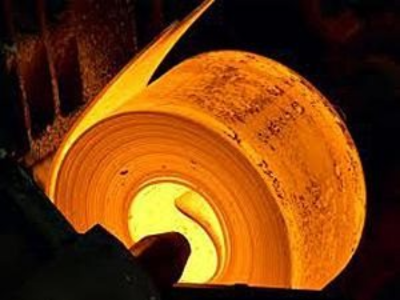

UNS S31000 Stainless Steel Coils, UNS S31008 Stainless Steel Strips, EN 1.4841 Stainless Steel Coils, Hot Rolled 310 Stainless Steel Coils, Cold Rolled 310S Stainless Steel Strips, No. 1 Finished 310 Stainless Steel Coils, 2B Finished 310S Stainless Steel Strips, etc. We provide comprehensive processing services for these products, such as slitting, cut-to-length, edge trimming, heat treatment, and polishing, tailored to your requirements.

| Standard | ASME SA240, ASTM A240, ASTM A480, DIN 1.4841, EN 10088-2, GB/T 4237, JIS G4304 |

|---|---|

| Grade | 1Cr25Ni20Si2, 25 20, S31008, SUS310S, X8CrNi25-21(1.4845) |

| Thickness | 0.1mm – 6.0mm (0.004in – 0.236in), Customized |

| Full Width | 10mm – 2000mm (0.39in – 78.7in), Customized |

| Surface Finish | 2B, BA, Customized, HL, No.1, No.4 |

| Technique | Annealed, Cold Rolled, Customized, Cut-to-Length, Edge Trimming, Hot Rolled, Leveling, Pickled, Slitting |

| Form | 2B Finished 310S Stainless Steel Strips, 310 Stainless Steel Sheets, 310S Stainless Steel Plates, BA 310 Stainless Steel Coils, Cold Rolled 310S Stainless Steel Strips, Hot Rolled 310 Stainless Steel Coils, Mill Edge 310 Stainless Steel Coils, No. 1 Finished 310 Stainless Steel Coils, Slit Edge 310S Stainless Steel Strips |

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

Japan, Canada, United States, France, Turkey, Germany, India, Taiwan, United Kingdom, Korea, Poland, Brazil, Vietnam, Italy, Russian Federation, Netherlands, Singapore, Australia, Ukraine, Belgium, Thailand, Iran, Morocco, Egypt, etc.

|

| lement | Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|

| 310 | ≤ 0.25% | ≤ 1.50% | ≤ 2.00% | ≤ 0.045% | ≤ 0.030% | 24.0-26.0% | 19.0-22.0% | Balance |

| 310S | ≤ 0.08% | ≤ 1.50% | ≤ 2.00% | ≤ 0.045% | ≤ 0.030% | 24.0-26.0% | 19.0-22.0% | Balance |

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 515 – 750 MPa | 74,700 – 108,800 psi |

| Yield Strength | ≥ 205 MPa | ≥ 29,700 psi |

| Elongation | ≥ 40% | ≥ 40% |

| Hardness (Brinell) | ≤ 217 HB | ≤ 217 HB |

| Hardness (Rockwell B) | ≤ 95 HRB | ≤ 95 HRB |

| Hardness (Vickers) | ≤ 225 HV | ≤ 225 HV |

| Elastic Modulus | 200 GPa | 29,000 ksi |

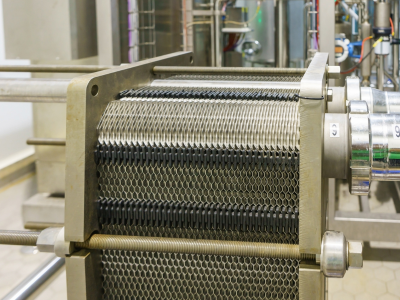

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info