SteelPRO Group is a leading supplier of high-quality stainless steel products and steel products. Whether you need custom stainless steel or the following products, we can meet your various needs.

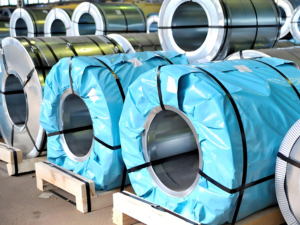

Our Product: Sheet & Plate, Stainless Steel Strip, 316L Stainless Steel Coil, 316L Cold Rolled Coil, SUS316L Hot Rolled Coil, 1.4404 Annealed Coil, Anti-fingerprint Coil, Multiple Surface Treatment Coil, etc.

| Standard | ASTM A240 / A240M, ASTM A480, EN 10088-2, GB/T 3280, JIS G4304 |

|---|---|

| Grade | 00Cr17Ni14Mo2, 0Cr18Ni12Mo2Ti, 1.4404, SUS316L, X2CrNiMo17-12-2 |

| Thickness | Cold Rolled Coil: 0.3 mm-6.0 mm (0.01-0.24 in), Customized, Hot Rolled Coil: 3 mm-50 mm (0.12-1.97 in) |

| Full Width | 3 mm-2000 mm (0.12-78.74 in), Customized |

| Surface Finish | 2B, 2D, BA, Embossed, etc., NO. 4, No. 8, No.1 |

| Technique | Annealing, Customized, Cutting, Hot Rolled, Cold Rolled, Polishing, Slitting |

| Form | Bright Annealed Coil, Cold Rolled Coil, Customized, Flat Plate and Sheet, Hot Rolled Coil, Strip |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Canada, Australia, India, Philippines, United Kingdom, Brazil, Colombia, Hong Kong, Indonesia, Korea, Mexico, Russian Federation, Singapore, South Africa, Argentina, Finland, Greece, Hungary, Israel, Malta, Netherlands, Norway, Portugal, Qatar, Romania, Saudi Arabia, Spain, Sweden, Taiwan, Ukraine, United Arab Emirates, etc.

|

| Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| ≤ 0.03 | ≤ 0.75 | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | ≤ 0.10 |

| Property | Metric Value | Imperial Value |

|---|---|---|

| Tensile Strength | 485 MPa – 620 MPa | 70,000 psi – 90,000 psi |

| Yield Strength | ≥ 170 MPa | ≥ 25,000 psi |

| Vickers Hardness | 150 – 190 HV | 150 – 190 HV |

| Brinell Hardness | ≤ 217 HB | ≤ 217 HB |

| Rockwell Hardness | 80 HRB | 80 HRB |

| Elongation | ≥ 40% | ≥ 40% |

| Elastic Modulus | 193 GPa | 28,000 ksi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

We ensure that every order is delivered to you in a timely and safe manner.

As a leading supplier of high-quality stainless steel products and steel materials, we meet the different needs of customers in different industries. Choosing us, you will enjoy: