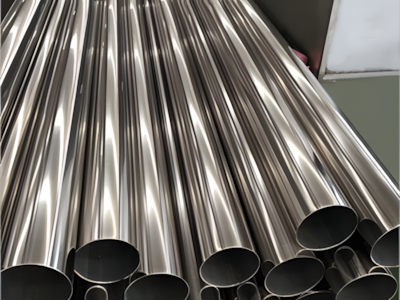

We are a steel and alloy manufacturer and supplier, providing you with various sizes and types of 309 stainless steel pipes. We provide a variety of processing and customization services, guaranteeing quality and timely delivery.

Our Product: 309 Seamless Pipe, Welded Pipe, 309 Round Pipe, Square Pipe, Rectangular Stainless Steel Pipe, 309 Small and Large Diameter Stainless Steel Pipe, Industrial/ Sanitary/Decorative Pipe.

| Standard | ANSI B36.10M, ASME B31.1, ASTM A213, ASTM A249, ASTM A269, ASTM A312 |

|---|---|

| Grade | 1Cr20Ni14Si2, SUH309, X15CrNiSi20-12 |

| Surface Finish | 2B, BA, Customized, No. 1, NO. 4, No.8 |

| Length | 1000mm-12000mm (39.37-472.44in), Customized |

| OD | 6mm-2000mm (0.236-78.74in), Customized |

| WT | 0.5mm-50mm (0.020-2 in), Customized |

| Shape | Customized, Hexagonal, Oval, Rectangular, Round, Square |

| Form | Bend Pipe, Customized, etc., Seamless Pipe, Tubes, Tubing, Welded Pipe |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, UK, Canada, Australia, India, South Africa, Philippines, Korea, Brazil, Russia, New Zealand, Turkey, Vietnam, Malaysia, Germany, Indonesia, etc.

|

| C | Ni | Si | S | Mn | P | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.20 max | 12.0 – 15.0 | 0.75 max | 0.03 max | 2.00 max | 0.045 max | 22.0 – 24.0 | – |

| Property | Imperial Units | Metric Units |

|---|---|---|

| Tensile Strength | 70 – 90 ksi | 480 – 620 MPa |

| Yield Strength | 35 – 45 ksi | 240 – 310 MPa |

| Vickers Hardness | 150 – 200 HV | 150 – 200 HV |

| Brinell Hardness | 140 – 160 HB | 140 – 160 HB |

| Rockwell Hardness | HRB 80 – 95 | HRB 80 – 95 |

| Elongation | 30 – 45% | 30 – 45% |

| Elastic Modulus | 28 – 30 x 10^6 psi | 190 – 210 GPa |

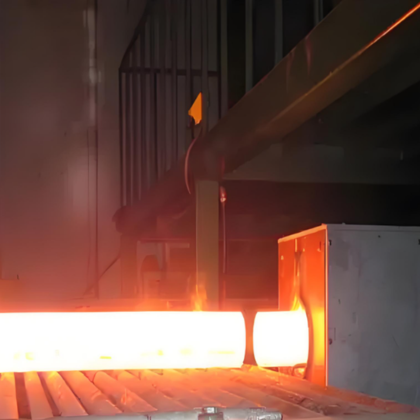

High temperature resistance: SS309 has excellent high temperature resistance and can work stably in environments up to 1000°C (1832°F).

Corrosion resistance: Although the corrosion resistance is better than ordinary carbon steel, it is slightly lower than other stainless steels (such as SS316).

Strength: It has high strength and toughness and can maintain structural stability under high temperature conditions.

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

Our commitment to quality extends to our packaging practices, ensuring your steel pipes arrive in top condition, ready for immediate use. If you have any specific packaging requirements or questions, please let us know and we will be happy to accommodate your needs.

Choose us for quality, customization, and reliability.