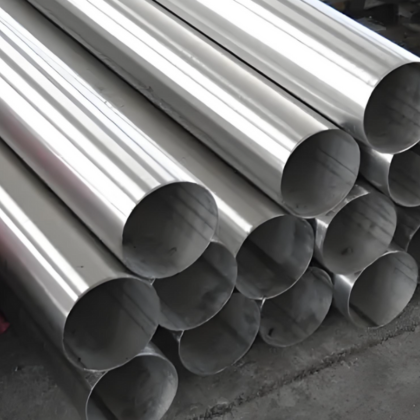

SteelPRO Group is a leading manufacturer and supplier of 310/310S Stainless Steel Pipe and Tubing in China. We provide:

UNS S31000 Stainless Steel Pipe, UNS S31008 Stainless Steel Pipe, AISI 310 Stainless Steel Pipe, AISI 310S Stainless Steel Pipe, 310/310S Stainless Steel Seamless Pipe, 310/310S Stainless Steel Welded Pipe, 310/310S Stainless Steel Polished Pipe, 310/310S Stainless Steel Brushed Tubing, 310/310S Stainless Steel Bright Annealed Tubing, 310/310S Stainless Steel Round Tubing, 310/310S Stainless Steel Square Tubing, and 310/310S Stainless Steel Rectangular Tubing. We provide processing for 310 and 310S stainless steel pipes and tubing, including cutting, bending, welding, and testing.

| Standard | ASTM A213, ASTM A269, ASTM A312, EN 10216-5, EN 10297-2, ISO 1127, JIS G3459 |

|---|---|

| Grade | 1Cr25Ni20Si2, 25 20, S31008, SUS310S, X8CrNi25-21 (1.4845) |

| Length | 6 meters – 12 meters (20 ft – 40 ft), Customized |

| OD | 6 mm – 610 mm (0.25 in – 24 in), Customized |

| WT | 0.5 mm – 50 mm (0.02 in – 2 in), Customized |

| Surface Finish | BA, Brushed, Customized, Mill, Polished |

| Shape | Customized, Rectangular, Round, Square |

| Form | 310/310S Stainless Steel Bar, 310/310S Stainless Steel Seamless Pipe, 310S/310 Bright Annealed Stainless Steel Tubing, 310S/310 Brushed Stainless Steel Tubing, 310S/310 Polished Stainless Steel Pipe, 310S/310 Stainless Steel Welded Pipe, Customized |

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, India, Turkey, Canada, Vietnam, Germany, France, United Kindom, Iran, Egypt, Brazil, Bangladesh, Philippines, Russia, Mexico, Ethiopia, Argentina, Hong Kong, Indonesia, Spain, Singapore, Thailand, Malaysia, Korea, etc.

|

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|

| 310 (%) | ≤ 0.25 | ≤ 2.00 | ≤ 1.50 | ≤ 0.045 | ≤ 0.030 | 24.00 – 26.00 | 19.00 – 22.00 | Balance |

| 310S (%) | ≤ 0.08 | ≤ 2.00 | ≤ 1.50 | ≤ 0.045 | ≤ 0.030 | 24.00 – 26.00 | 19.00 – 22.00 | Balance |

| Property | 310 Pipe | 310S Pipe | 310 Tubing | 310S Tubing |

|---|---|---|---|---|

| Tensile Strength (UTS) | 515 – 730 MPa (75,000 – 106,000 psi) | 515 – 690 MPa (75,000 – 100,000 psi) | 520 – 740 MPa (76,000 – 107,000 psi) | 520 – 700 MPa (76,000 – 102,000 psi) |

| Yield Strength | 205 MPa (min) (30,000 psi min) | 205 MPa (min) (30,000 psi min) | 210 MPa (min) (31,000 psi min) | 210 MPa (min) (31,000 psi min) |

| Elongation | 40% (min) | 40% (min) | 38% (min) | 38% (min) |

| Modulus of Elasticity | 200 GPa (29,000 ksi) | 200 GPa (29,000 ksi) | 200 GPa (29,000 ksi) | 200 GPa (29,000 ksi) |

| Hardness (Brinell) | 170 – 210 HB | 160 – 195 HB | 175 – 215 HB | 165 – 200 HB |

| Hardness (Rockwell B) | 85 – 95 HRB | 80 – 93 HRB | 86 – 96 HRB | 82 – 90 HRB |

| Hardness (Vickers) | 175 – 220 HV | 165 – 210 HV | 180 – 225 HV | 170 – 210 HV |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info