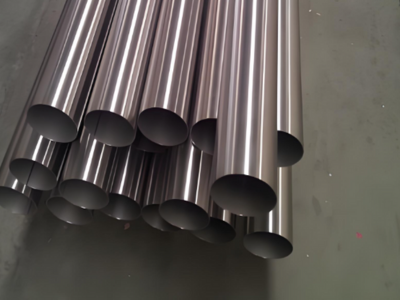

With rich experience and expertise, we are one of the leading 316L Pipe manufacturers and suppliers. We have sufficient stock of 316L stainless steel pipes in various sizes and types and supply them worldwide.

Our Product: 316L seamless pipe, 316L stainless steel tube, seamless pipe & tube, ERW pipe, welded pipe, assembled pipe, LSAW pipe, round pipe, square pipe, hexagonal pipe, hollow pipe & tube, cold drawn pipe, hot rolled pipe, cold rolled tube, etc.

| Standard | ANSI B36.10M, ASTM A213, ASTM A312, EN 10216-5, ISO 1127, JIS G3459 |

|---|---|

| Grade | 00Cr17Ni14Mo2, 0Cr18Ni12Mo2Ti, 1.4404, SUS316L, X2CrNiMo17-12-2 |

| Length | 6 m-12 m (20-40 ft), Customized |

| OD | 6 mm-600 mm (0.2-24 in), Customized |

| WT | 0.5 mm-50 mm (0.02-2 in), Customized |

| Surface Finish | 2B, BA, Brushed, Customized, No.1, No.4, No.8, Polished |

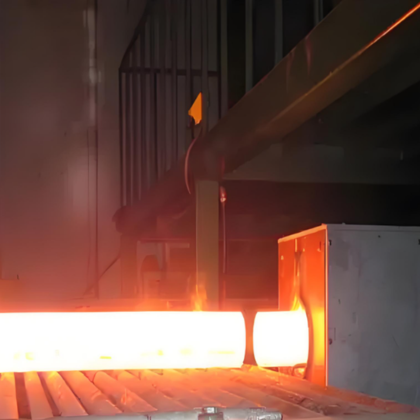

| Technique | Cold Drawing, Cold Rolling, etc., Heat Treatment, Welding |

| Form | Capillary Pipe & Tube, Customized, Heat Exchanger Tube, Industrial Pipe, Plain/Beveled/Treaded End Tube & Pipe, Precision Pipe & Tube, Seamless Pipe & Tube, Welded Pipe & Tube |

|

Terms |

Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, India, Canada, United Kingdom, Australia, Korea, Hongkong, New Zealand, Philippines, Qatar, Russian Federation, Bangladesh, Indonesia, Norway, Pakistan, Saudi Arabia, Singapore, South Africa, United Arab Emirates, Vietnam, etc.

|

| Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| ≤ 0.03 | ≤ 0.75 | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | ≤ 0.10 |

| Property | Imperial Units | Metric Units |

|---|---|---|

| Tensile Strength | 70 – 90 ksi | 480 – 620 MPa |

| Yield Strength | 35 – 45 ksi | 240 – 310 MPa |

| Vickers Hardness | 150 – 200 HV | 150 – 200 HV |

| Brinell Hardness | 140 – 160 HB | 140 – 160 HB |

| Rockwell Hardness | HRB 80 – 95 | HRB 80 – 95 |

| Elongation | 30 – 45% | 30 – 45% |

| Elastic Modulus | 28 – 30 x 10^6 psi | 190 – 210 GPa |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

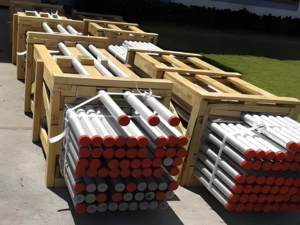

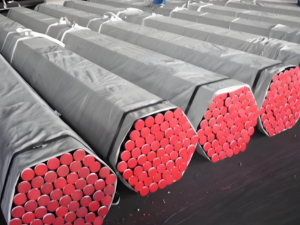

At SteelPRO Group, we understand that the quality of packaging is just as important as the quality of the product itself. To ensure that our 316L stainless steel pipes reach you in perfect condition, we offer the following packaging solutions:

By choosing SteelPRO Group, you will be working with a reliable, quality-driven, customer-centric steel manufacturer and supplier. We are committed to exceeding your expectations with every order.