SteelPRO Group is a leading manufacturer and supplier of high quality 316Ti stainless steel pipes, plates and coils. We have a wide range of products and can customize steel in different types, forms, sizes and specifications.

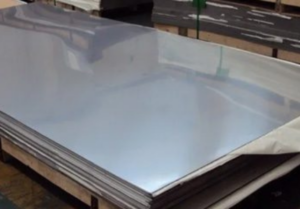

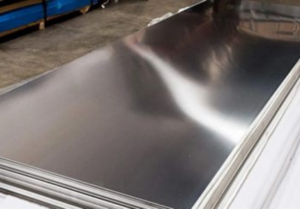

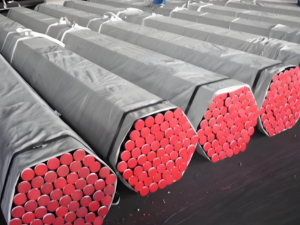

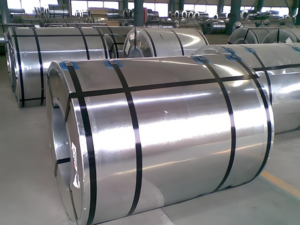

Our products: 316Ti stainless steel seamless pipes, welded pipes, round pipes, square pipes, 316Ti plates and sheets, 1.4571 gaskets, perforated plates, checkered plates, SUS 316Ti strips, 316Ti hot rolled and cold rolled stainless steel coils, surface treated coils, etc.

| Standard | ASTM A213, ASTM A240, ASTM A312, EN 10028-7, EN 10088-2, EN 10216-5 |

|---|---|

| Grade | 0Cr18Ni12Mo2Ti, 1.4571, 1Cr18Ni12Mo2Ti, SUS316Ti, X6CrNiMoTi17-12-2 |

| Length | Customized, Pipe: 6 m-12 m (20-40 ft), Plate: 2 m-6 m (6.6-20 ft) |

| OD | Customized, Pipe: 6 mm-600 mm (0.24-24 in) |

| WT | Customized, Pipe: 1 mm-50 mm (0.04-2 in) |

| Full Width | Customized, Plate & Coil: 1000 mm-2000 mm (39.37-78.74 in) |

| Thickness | Coil: 0.3 mm-8 mm (0.012-0.3 in), Customized, Plate: 0.5 mm-50 mm (0.02-2 in) |

| Form | BA Pipe & Coil, Brushed Coil, Coated Coil, Cold-Rolled Plate & Coil, Embossed Plate, Hot-Rolled Plate & Coil, Mirror Finish Plate, Pickled Plate, Seamless Pipe & Tube, Sheet, Square/Rectangular/Oval/Special-shaped Pipe, Strip, Tubing, Welded Pipe, Wire |

| Surface | 2B, 2D, AP, BA, Brushed, Customized, Mirror, NO.4, NO.8, Polished |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

Germany, Turkey, United States, India, France, United Kingdom, Korea, Poland, Taiwan, Russian Federation, Australia, Netherlands, Brazil, Czech Republic, Sweden, Greece, Canada, Finland, Iran, Austria, Portugal, Indonesia, Switzerland, Romania, Spain, Malaysia, Norway, Denmark, Bulgaria, Saudi Arabia, Belgium, Ukraine, United Arab Emirates, etc.

|

| Element | C | Mn | Si | P | S | Cr | Ni | Mo | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | ≤ 0.08 | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | 5x C – 0.70 |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 515 – 750 MPa | 74.7 – 108.7 ksi |

| Yield Strength | 205 MPa | 29.7 ksi |

| Vickers Hardness | 152 – 200 HV | — |

| Brinell Hardness | 146 – 217 HB | — |

| Rockwell Hardness | 79 HRB | — |

| Elongation | 35% | 35% |

| Elastic Modulus | 193 GPa | 28.0 x 10^6 psi |

316Ti Pipe, Plate, Coil are all 316Ti stainless steel, and their heat treatment methods are the same.

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

Choose us and experience the superior quality of 316Ti stainless steel.