347 Stainless Steel Wire | Pipe | Rod

347 Stainless Steel Wire | Pipe | Rod

SteelPRO Group is a leading manufacturer and supplier of 347 stainless steel wire, pipe, and rod in China. We provide:

EN 1.4550 Stainless Steel Wire, S34700 Stainless Steel Rod, 347H Stainless Steel Wire, 347H Stainless Steel Pipe, 347H Stainless Steel Rod, Polished 347 Stainless Steel Wire, Annealed 347 Stainless Steel Rod, Seamless 347 Stainless Steel Pipe, Welded 347 Stainless Steel Pipe, etc. We offer precision cutting, surface polishing, custom bending, threading, welding, and heat treatment services.

| Standard | ASME SA276, ASME SA312, ASTM A276, ASTM A312, ASTM A580, DIN 17456, EN 10216-5, JIS G4303 |

|---|---|

| Grade | 347S31, X6CrNiNb18-10 (1.4550)/19 9 Nb, Z6CNNb18-10 |

| Length | 1000mm – 12000mm (39.37in – 472.44in), Customized |

| Diameter | Customized, Rod: 1mm – 200mm (0.04in – 7.87 in), Wire: 0.1mm – 10mm (0.004in – 0.394in) |

| Pipe's OD | 6mm – 610mm (0.24in – 24in), Customized |

| Pipe's WT | 0.5mm – 30mm (0.02in – 1.18in), Customized |

| Shape | Customized, Elliptical, Flat, Hexagonal, Oval, Rectangular, Round, Square |

| Surface Finish | Annealed, Bright, Brushed, Customized, Matte, Passivated, Pickled, Polished |

| Technique | Annealing, Cold Drawing, Customized, Hot Rolling, Seamless Production, Welding |

| Form | 347 Cold Drawn Stainless Steel Wire, 347 Hot Rolled Stainless Steel Rod, 347 Polished Stainless Steel Wire, 347 Seamless Stainless Steel Pipe, 347 Stainless Steel Tube, 347H Stainless Steel Pipe, 347H Stainless Steel Rod, 347H Stainless Steel Wire, Customized |

347 Stainless Steel Wire | Pipe | Rod

347 Stainless Steel Wire | Pipe | Rod

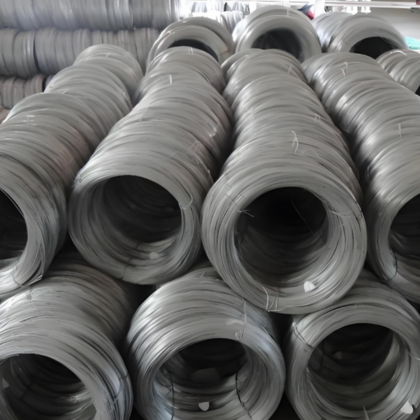

- 347 Stainless Steel Wire: A high-quality austenitic stainless steel wire, known for its flexibility and resistance to corrosion and high temperatures. Commonly cold drawn, this wire is ideal for aerospace, chemical processing, and power generation due to its formability and mechanical strength, as well as its stability against intergranular corrosion.

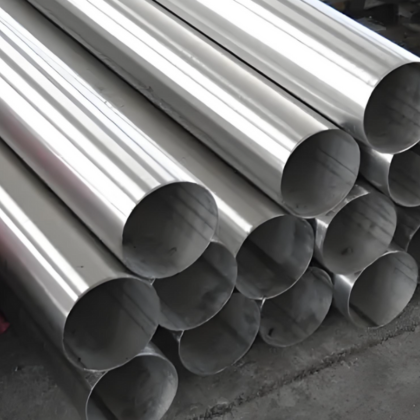

- 347 Stainless Steel Pipe: A durable austenitic stainless steel pipe, available in various diameters and lengths for transporting fluids and gases in challenging environments. Made through hot rolling and welding, it offers excellent corrosion resistance, temperature stability, and weldability, making it ideal for petrochemical, chemical processing, and power generation.

- 347 Stainless Steel Rod: A strong austenitic stainless steel rod, with round, square, or hexagonal cross-sections, designed for high strength and heat resistance applications. Typically produced via hot rolling or cold finishing, it offers good machinability and stability against intergranular corrosion, perfect for structural uses in aerospace, petrochemical, and power generation industries.

Business Terms

Business Terms

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

India, Australia, Korea, Brazil, Russia, New Zealand, Turkey, Vietnam, Malaysia, Germany, Indonesia, etc.

|

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Niobium (Nb) | Nitrogen (N) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 0.08 max | 2.00 max | 0.75 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 9.00 – 13.00 | 0.20 min | 0.10 max | Balance |

Mechanical Properties

Mechanical Properties

| Property | Wire | Pipe | Rod |

|---|---|---|---|

| Tensile Strength | 620 – 850 MPa (90,000 – 123,000 psi) | 515 – 690 MPa (74,700 – 100,000 psi) | 515 – 690 MPa (74,700 – 100,000 psi) |

| Yield Strength | 310 – 485 MPa (45,000 – 70,000 psi) | 205 – 310 MPa (29,700 – 45,000 psi) | 205 – 310 MPa (29,700 – 45,000 psi) |

| Elongation | 20% min | 40% min | 35% min |

| Hardness (Brinell) | 200 – 250 HB | 160 – 201 HB | 160 – 201 HB |

| Hardness (Rockwell B) | 80 – 95 HRB | 80 – 95 HRB | 80 – 95 HRB |

| Hardness (Vickers) | 200 – 250 HV | 150 – 210 HV | 150 – 210 HV |

| Modulus of Elasticity | 193 – 200 GPa (28 – 29 x 10^6 psi) | 193 – 200 GPa (28 – 29 x 10^6 psi) | 193 – 200 GPa (28 – 29 x 10^6 psi) |

Heat Treatment

Heat Treatment

- Solution Annealing

- Temperature: 1038°C – 1149°C (1900°F – 2100°F)

- Process: Heat and rapidly cool to prevent carbide formation and maintain corrosion resistance.

- Annealing

- Temperature: 1010°C – 1120°C (1850°F – 2050°F)

- Process: Heat and cool slowly to relieve stresses and improve ductility and toughness.

- Stress Relieving

- Temperature: 200°C – 400°C (392°F – 752°F)

- Process: Heat below the critical range and cool to reduce residual stresses.

- Stabilizing Annealing

- Temperature: 870°C – 900°C (1600°F – 1650°F)

- Process: Heat and cool to stabilize carbides and prevent corrosion.

- Normalizing, Quenching, Tempering: Not used due to stable austenitic structure.

Characteristic

Characteristic

- 347 Stainless Steel Wire

- High strength for tension and stress.

- Resistant to corrosion in harsh conditions.

- Easily shaped for versatile applications.

- Stable at high temperatures.

- 347 Stainless Steel Pipe

- High corrosion resistance in various environments.

- Strong and ductile for high-pressure and high-temperature use.

- Seamless and welded options for versatile applications.

- Heat resistant for high-temperature industries.

- 347 Stainless Steel Rod

- High strength and toughness for structural use.

- Easily welded without corrosion risk.

- Versatile for aerospace, automotive, and manufacturing.

- Stable at high temperatures for heat-resistant applications.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

Packing

Packing

We provide premium packaging services for 347 stainless steel wires, pipes and rods.

- Standard Packaging: All products are securely wrapped in waterproof, corrosion-resistant materials. Each product is strapped with durable steel bands.

- Wooden Crates or Pallets: For added protection, especially for international shipping, the products may be placed in sturdy wooden crates or on pallets.

- Custom Packaging: Custom packaging options are available upon request, including specific crate sizes, special coatings, additional protective materials like foam padding or bubble wrap, and other tailored solutions to meet specific needs and ensure optimal protection during transit.

Why Choose Us

Why Choose Us

- High-Quality Standards: Our 347 Stainless Steel Wires, Pipes and Rods meet strict standards for durability, corrosion resistance, and heat performance.

- Versatile Range: Various sizes, shapes, and finishes for diverse applications.

- Precision Manufacturing: Advanced techniques ensure accurate dimensions and quality.

- Custom Solutions: Tailored fabrication and cutting services.

- Reliable Service: Fast delivery and responsive support.

- Competitive Pricing: High-quality products at great value.