SS 303Se Plate, Sheet, Tubing & Round Bar

SS 303Se Plate, Sheet, Tubing & Round Bar

SteelPRO Group is a trusted 303Se stainless steel supplier and manufacturer. We provide custom solutions, precision cutting, fast delivery, quality control and technical support to meet the needs of our customers.

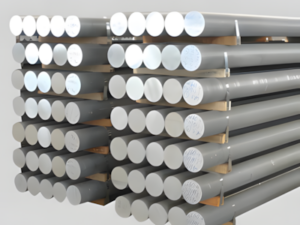

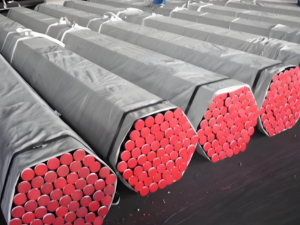

Our Products: 303Se Hot Rolled Plate, S30323 Cold Rolled Sheet, Heat Treated Plate, Embossed Sheet, 303Se Seamless Tubing, 303Se Round Bar, Square Tubing, Turned Bar, Cold Drawn Bar, SUS303Se Welded Tubing, 303Se Polished Plate, etc.

| Standard | ASTM A213, ASTM A240, ASTM A276, ASTM A312, ASTM A479 |

|---|---|

| Grade | 1Cr18Ni9Se, SUS303Se, UNS S30323 |

| Length | 1000 mm-6000 mm (39.37-236.22 in), Customized |

| Diameter | Customized, Round Bar: 10 mm-300 mm (0.39-12 in), Tube (OD) : 6 mm-300 mm (0.24-12 in) |

| Thickness | Customized, Plate & Sheet: 0.5 mm-100 mm (0.02-3.94 in), Tube (OD) : 0.5 mm-10 mm (0.02-0.39 in) |

| Full Width | Customized, Plate & Sheet: 1000 mm-2000 mm (39.37-78.74 in) |

| Shape | Customized, Tube: Round/Square/Rectangular/Hexagonal/Flat |

| Surface Finish | 2B, BA, Brushed, etc., No.1, No.4, Pickling, Polishing, Turned |

| Form | 303Se Plate, 303Se Round Bar, 303Se Sheet, 303Se Tube, Bar, Coil, Cold Drawn Bar, Cold Rolled Sheet, etc., Foil, Hot Rolled Plate, Pipe, PolishED Bar, Rod, Seamless Tube, Strip, U-bend Tube, Welded Tube |

SS 303Se Plate, Sheet, Tubing & Round Bar

SS 303Se Plate, Sheet, Tubing & Round Bar

- 303Se plate is commonly used in the manufacturing of industries such as automobiles, aerospace and chemical processing, while 303 Se sheet is thinner and suitable for decorative panels, kitchen equipment and food processing.

- 303Se tubing is commonly used in applications such as pipelines, fluid transfer, heat exchangers and decorative structures in industries such as automobiles and chemical processing.

- 303Se round bar is commonly used to produce bolts, nuts, shafts and other precision machined parts in industries such as automobiles, aerospace and industrial equipment manufacturing.

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Canada, India, Australia, Mexico, Russian Federation, United Kingdom, Poland, Netherlands, Turkey, Finland, France, Germany, Malaysia, Taiwan, etc.

|

Chemical Compositions

Chemical Compositions

| Element | Chromium (Cr) | Nickel (Ni) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Selenium (Se) | Carbon (C) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 17.0 – 19.0 | 8.0 – 10.0 | ≤ 2.0 | ≤ 1.0 | ≤ 0.20 | 0.15 – 0.35 | 0.15 – 0.35 | ≤ 0.15 | ≤ 0.10 |

Mechanical Properties

Mechanical Properties

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 515 – 740 MPa | 74.7 – 107 ksi |

| Yield Strength | 205 MPa | 29.7 ksi |

| Vickers Hardness | 155 – 190 HV | — |

| Brinell Hardness | 170 – 200 HB | — |

| Rockwell Hardness | 79 HRB | — |

| Elongation | 35% | 35% |

| Elastic Modulus | 193 GPa | 28.0 × 10^6 psi |

Heat Treatment

Heat Treatment

- Solution Annealing: Applicable to 303Se Plate, Sheet, Tube, Round Bar. Heat 303Se stainless steel to 1010°C to 1120°C, then cool rapidly (usually water quenching or air cooling).

- Stress Relieving Annealing: Applicable to 303Se Plate, Sheet, Tube, Round Bar. Usually carried out at a lower temperature (about 300°C to 400°C), the main purpose is to remove the residual internal stress after cold working or welding.

- Annealing: Applicable to 303Se Plate, Sheet, Tube, Round Bar. Heat the material to 800°C to 900°C, then cool slowly.

- Hydrogen Relief Annealing: Applicable to 303Se Plate, Sheet, Tube, Round Bar. Annealing is performed at a lower temperature (such as 200°C to 400°C) to remove hydrogen embrittlement caused by electroplating, pickling or welding.

- Precipitation Hardening, Nitriding, Quenching and Tempering are not applicable to 303Se stainless steel.

Characteristic

Characteristic

- 303Se plate offers excellent machinability, making it easy to process. It also has good corrosion resistance, ensuring durability in various environments. The plate is strong and weldable, allowing for secure connections and fabrication.

- 303Se sheet is known for its high machinability. It provides a smooth surface finish, ideal for precise applications. The sheet also has good corrosion resistance, ensuring longevity in harsh environments.

- 303Se tubing boasts good machinability, allowing for efficient manufacturing. Its high corrosion resistance makes it suitable for applications in harsh conditions. The tube is durable and strong, ensuring reliable performance in structural or fluid-handling roles. It is also easily weldable, allowing for flexible design and assembly.

- 303Se round bar is prized for its exceptional machinability, making it ideal for precision parts. It also provides good corrosion resistance, ensuring long-lasting performance. The bar is easy to fabricate, and its high strength and durability make it suitable for load-bearing applications.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

2B Surface

2D Surface

BA Surface

6K Surface

8K Surface

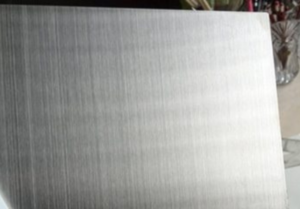

HL Surface

NO.1 Surface

NO.4 Surface

Embossed Surface

Packing

Packing

At SteelPRO, we understand the importance of safe and secure packaging to ensure that your 303Se stainless steel products arrive intact.

- Safe Packaging: Each product is carefully packed with corrosion-resistant materials to prevent moisture and environmental damage.

- Custom Packaging Solutions: Custom packaging is provided for plates, sheets, tubes and round bars to ensure safe and damage-free delivery.

- Shockproof Protection: Our packaging includes shockproof materials to prevent movement or damage during shipping.

- Weatherproof Sealed: Products are sealed with weatherproof materials to withstand all shipping conditions, ensuring that products arrive intact.

- Eco-friendly Packaging Options: We offer recyclable and eco-friendly packaging solutions that support sustainability while providing protection.

Why Choose Us

Why Choose Us

SteelPRO is dedicated to providing premium 303Se stainless steel products. Whether you need plates, sheets, tubes or round bars, we guarantee the highest quality and performance.

- Quality Assurance: We specialize in 303Se stainless steel and provide first-class materials that meet the most stringent industry standards.

- Precision Tailoring: Custom sizes, thicknesses and finishes are available to perfectly meet your application requirements.

- Superior Corrosion Resistance: Our 303Se products have excellent corrosion resistance and provide long-lasting durability.

- Consistent Quality: Each batch of products is rigorously tested to ensure consistent strength and reliability.

- Timely Delivery: Through efficient logistics, we ensure that your products are delivered on time to keep your projects on schedule.