SteelPRO Group is a leading manufacturer and supplier of 347 stainless steel sheets and plates in China. We provide:

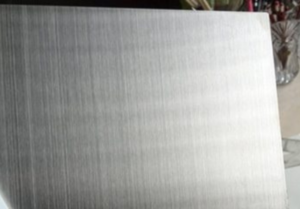

347 Hot-Rolled / Cold-Rolled Plates, 347 Polished Sheets, 347 Brushed Finish Sheets, 347 2B Finish Sheets, 347 Mirror Finish Plates, 347 Perforated Sheets, 347 Diamond Tread Plates, EN 1.4550 Stainless Steel Plate/Sheet, UNS S34700 Stainless Steel Plate/Sheet, etc. We offer services such as precision cutting, surface polishing, custom sizing, welding, and thorough quality inspection.

| Standard | ASTM A240 / ASME SA240, BS 1449, DIN 17441, EN 10088-2, GOST 7350, ISO 15510, JIS G4304 |

|---|---|

| Grade | 347S31, X6CrNiNb18-10 (1.4550)/19 9 Nb, Z6CNNb18-10 |

| Length | 2000mm – 12000mm (78.74in – 472.44in), Customized |

| Thickness | 0.3mm – 100mm (0.012in – 3.94in), Customized |

| Width | 1000mm – 3000mm (39.37in – 118.11in), Customized |

| Surface Finish | 2B, BA, Customized, Mirror, No.1, No.4 |

| Technique | Hot Rolled, Cold Rolled |

| Form | 347 Stainless Steel Coil, 347 Stainless Steel Strip, Brushed 347 Stainless Steel Sheet, Cold-Rolled 347 Stainless Steel Plate, Customized, Hot-Rolled 347 Stainless Steel Plate, Mirror Finish 347 Stainless Steel Plate, Perforated 347 Stainless Steel Sheet, Polished 347 Stainless Steel Sheet |

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

Korea, United States, Russia, India, Brazil

|

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Niobium (Nb) | Nitrogen (N) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 0.08 max | 2.00 max | 0.75 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 9.00 – 13.00 | 10 x C min | 0.10 max | Balance |

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 515 MPa min | 74,700 psi min |

| Yield Strength | 205 MPa min | 29,700 psi min |

| Elongation | 40% min | 40% min |

| Hardness (Brinell) | 201 max | 201 max |

| Hardness (Rockwell B) | 95 max | 95 max |

| Hardness (Vickers) | 210 max | 210 max |

| Modulus of Elasticity | 193-200 GPa | 28-29 x 10^6 psi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

We provide premium packaging services for 347 stainless steel plates and sheets to ensure safe and secure delivery.