SteelPRO Group is a leading manufacturer and supplier of 347H Stainless Steel Plates manufacturer in China. We provide:

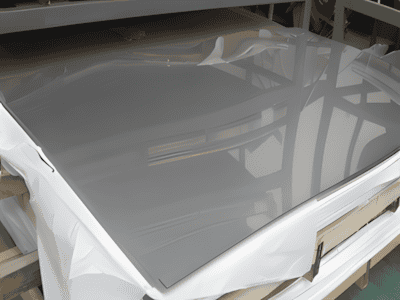

1.4961 Stainless Steel Plate, S34709 Stainless Steel Plate, AISI 347H Stainless Steel Plate, Hot Rolled /Cold Rolled 347H Stainless Steel Plates, 2B Finish 347H Stainless Steel Plates, No.4 Finish 347H Stainless Steel Plates, Mirror Finish 347H Stainless Steel Plates, Custom Cut 347H Stainless Steel Plates, etc. Our services include precision cutting, mirror polishing, professional welding, and comprehensive quality inspections.

| Standard | ASTM A240、ASME SA-240、EN 10088-2、JIS G4304、GB/T 4237 |

|---|---|

| Grade | X7CrNiNb18-10 (1.4912), S34709, SUS347H |

| Length | 2000mm – 6000mm (78.74 in – 236.22 in) |

| Thickness | 0.3mm – 100mm (0.012 in – 3.94 in) |

| Width | 1000mm – 2000mm (39.37 in- 78.74 in) |

| Surface Finish | 2B, Customized, Mirror, No.1, No.4 |

| Technique | Hot Rolled, Cold Rolled |

| Form | 347H Stainless Steel Coil, 347H Stainless Steel Sheet, 347H Stainless Steel Strip, Annealed 347H Stainless Steel Plate, Corrugated Plate, Diamond Tread Plate, Hot Rolled/Cool Rolled 347H Stainless Steel Plate, Perforated Plate, Pickled and Passivated 347H Stainless Steel Plate, Polished 347H Stainless Steel Plate |

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: | United States, India, Canada, Hong Kong, Singapore, Japan, Germany |

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Niobium (Nb) | Nitrogen (N) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 0.04 – 0.10 | Max 2.00 | Max 0.75 | Max 0.045 | Max 0.030 | 17.00 – 19.00 | 9.00 – 13.00 | 10 x C min | Max 0.10 | Balance |

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 515 MPa min | 74,694.57 psi min |

| Yield Strength | 205 MPa min | 29,732.79 psi min |

| Elongation at Break | 40% min | N/A |

| Hardness (Rockwell B) | 95 max | N/A |

| Modulus of Elasticity | 193 – 200 GPa | 27,992,334.00 – 29,007,600.00 psi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

We implement a comprehensive packaging process to ensure product integrity during transportation and storage. Each 347H stainless steel plate is individually wrapped, cushioned, securely packed in wooden boxes/crates, stacked on pallets, strapped, and clearly labeled for protection and identification throughout the supply chain.

We offer tailored packaging solutions to meet unique customer requirements, including custom box/pallet dimensions and additional protective materials for sensitive applications. For inquiries or special requests, please contact our team.