SteelPRO Group is a specialized supplier of stainless steel plates:

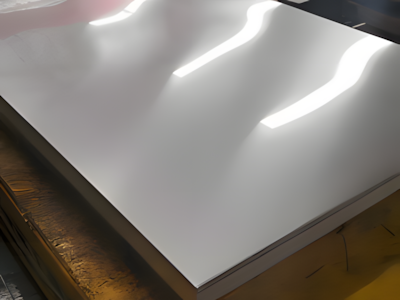

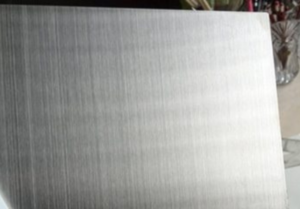

We provide hot rolled 409 stainless steel plates, cold rolled 409 stainless steel plates, polished 409 stainless steel plates, and clad 409 stainless steel plates. We provide cutting, grinding, polishing, drilling, bending, patterning, heat treatment, and surface treatment services.

| Standard | ASTM A240 |

|---|---|

| Grade | 0Cr11Ti, 1.4512, SUH409 |

| Length | 2400 mm (94.49 inch) to 6000 mm (236.22 inch), Customized |

| Thickness | 6 mm (0.24 inch) to 150 mm (5.9 inch), Customized |

| Width | 1200 mm (47.24 inch) to 2000 mm (78.74 inch) |

| Surface Finish | 2B, BA, No.1, No.3, No.4, Patterned, Polished |

| Technique | Hot Rolling, Cold Rolling, Annealing |

| Form | Checker Plate, Clad Plate, Cut-to-Size Plate and Sheet, Flat Plate and Sheet, Perforated Plate and sheet, Tread Plate |

| Terms | Specifications |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Australia, India, Canada, Pakistan, Portugal, United Kingdom, Afghanistan, Albania, Algeria, American Samoa, Andorra, Angola, Anguilla, Antigua And Barbuda, Argentina, Armenia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, etc.

|

| Element | Carbon | Manganese | Silicon | Chromium | Nickel | Phosphorus | Sulfur | Iron |

|---|---|---|---|---|---|---|---|---|

| Range (%) | ≤ 0.08 | 0.30–0.60 | 0.50–1.00 | 10.50–11.50 | ≤ 0.50 | ≤ 0.04 | ≤ 0.03 | Balanc |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 450-600 MPa | 65-87 ksi |

| Yield Strength | 205 MPa | 30 ksi |

| Vickers Hardness | 150-180 HV | 150-180 HV |

| Brinell Hardness | 150-180 HB | 150-180 HB |

| Rockwell Hardness | B80-B90 | B80-B90 |

| Elongation | 20% | 20% |

| Elastic Modulus | 200 GPa | 29,000 ksi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

SteelPRO Group is a Manufacturer and solutions provider for specialty steel, offering custom services and 100% quality assurance!

Choose us and we can offer you: