17-4PH Stainless Steel Rod & Plate

17-4PH Stainless Steel Rod & Plate

SteelPRO Group is a trusted 17-4 PH stainless steel manufacturer and supplier specializing in a variety of services including custom orders, cutting and processing. We offer high-quality SS 17-4 products that meet AMS 5604 standards in various forms to suit different needs.

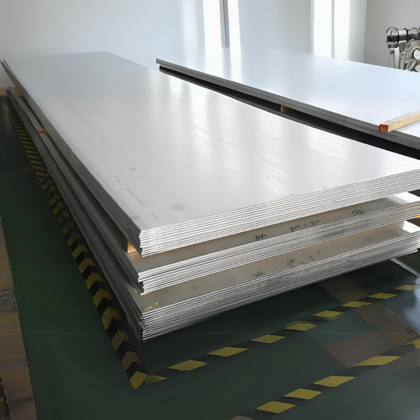

Our product: 17-4 PH round rod, S17400 square bar, solid rod, 17-4 PH cold drawn rod, 1.4542 hot rolled plate, 17-4 PH cold rolled plate, SUS630 clad plate, 17-4 PH flat plate, sheet, polished rod, hot rolled bar, perforated plate, etc.

| Standard | AMS 5604, AMS 5643, ASTM A564, ASTM A693 |

|---|---|

| Grade | 1.4542, SUS630, UNS S17400, X5CrNiCuNb16-4 |

| Length | 2 m-6 m (6.6-20 ft), Customized |

| Diameter | Customized, Rod: 6 mm-300 mm (0.2-12 in) |

| Thickness | Customized, Plate: 3 mm-150 mm (0.12-6 in) |

| Full Width | Customized, Plate: 1000 mm-2500 mm (39.37-98.43 in) |

| Surface Finish | Black Surface, Customized, Grounded, Machining for plate, Peeled/Turned, Polished |

| Form | Bar, Coil, cold-drawn rods, cold-rolled sheets, Customized, flat plates & sheet, hexagonal rods, hollow rods, hot-rolled bars, hot-rolled plates, patterned plates, perforated plates, polished plates, polished rods, round rods, Sheet, solid bars, special-shaped rods, square rods, Strip, textured plates, threaded rods |

17-4PH Stainless Steel Rod & Plate

17-4PH Stainless Steel Rod & Plate

- 17-4PH rod is a precipitation-hardening martensitic stainless steel. It is available in round, square, and hexagonal shapes. This material offers high strength, excellent corrosion resistance, good weldability, and easy machining. Due to these properties, 17-4PH rods are commonly used in aerospace components, chemical processing equipment, and marine applications like pump shafts and valve parts.

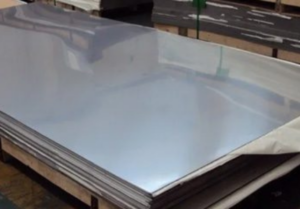

- 17-4PH plate is also a precipitation-hardening martensitic stainless steel. It is typically available in flat, rectangular sheets. The material is known for its high strength, good toughness, corrosion resistance, and ease of fabrication. These plates are often used in structural parts for aircraft, gas turbines, and nuclear reactors, as well as medical instruments and food processing machinery.

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, United Kingdom, India, Australia, France, Italy, Saudi Arabia, Spain, Canada, Denmark, Finland, Israel, Japan, Korea, Malaysia, Mexico, Pakistan, Russian Federation, Sweden, Thailand, Turkey, etc.

|

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Chromium (Cr) | Nickel (Ni) | Copper (Cu) | Molybdenum (Mo) | Sulfur (S) | Phosphorus (P) | Vanadium (V) |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | ≤ 0.07 | ≤ 1.00 | ≤ 1.00 | 15.00 – 17.50 | 3.00 – 5.00 | 3.00 – 5.00 | ≤ 0.50 | ≤ 0.030 | ≤ 0.040 | ≤ 0.10 |

Mechanical Properties

Mechanical Properties

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 515 – 750 MPa | 74.7 – 108.7 ksi |

| Yield Strength | 205 MPa | 29.7 ksi |

| Vickers Hardness | 152 – 200 HV | — |

| Brinell Hardness | 146 – 217 HB | — |

| Rockwell Hardness | 79 HRB | — |

| Elongation | 35% | 35% |

| Elastic Modulus | 193 GPa | 28.0 × 10^6 psi |

Heat Treatment

Heat Treatment

- Solution Annealing: Suitable for both plate and bar. Heat the material to 1020-1065°C (1870-1950°F) and air cool. This process dissolves alloying elements and homogenizes the structure.

- Precipitation Hardening is the most common heat treatment process for 17-4PH and increases strength and hardness.

- H900: Suitable for bar, but not recommended for plate. Heat the material to 482°C (900°F) for 1 hour and air cool.

- H925: Suitable for both plate and bar. Heat to 496°C (925°F) for 1 hour and air cool.

- H1025: Suitable for both plate and bar. Heat to 552°C (1025°F) for 1 hour and air cool.

- H1075: Suitable for plate and bar. Heat to 579°C (1075°F) for 1 hour, then air cool.

- H1150: Suitable for plate and bar. Heat to 621°C (1150°F) for 4 hours, cool to room temperature, reheat to 621°C for 4 hours, then air cool.

- H1150M: Suitable for plate and bar. Heat to 621°C (1150°F) for 4 hours, cool to room temperature, then reheat to 760°C (1400°F) for 2 hours, then air cool.

- H1150D: Suitable for bar, but not often used for plate. Same as H1150M, but with a more controlled second aging stage.

- Stress Relief: Suitable for plate and bar. Heat to approximately 290-425°C (550-800°F) and hold for 1-2 hours to reduce internal stresses without significantly changing mechanical properties.

- Annealing: 17-4PH is not normally fully annealed as this would eliminate the benefits of its precipitation hardening properties.

Characteristic

Characteristic

- 17-4PH Rods

- High Strength: 17-4PH bar has excellent tensile and yield strength, especially in conditions such as H900. This makes it suitable for high stress applications.

- Good Machinability: It is relatively easy to machine in the annealed state, allowing for efficient production of parts.

- Corrosion Resistance: Like other stainless steels, 17-4PH rod has strong resistance to atmospheric corrosion and a variety of chemicals.

- Weldability: It can be welded in the annealed state and then heat treated to maintain its mechanical properties.

- 17-4PH Plates

- Excellent Toughness: 17-4PH plate has excellent toughness, especially in high temperature aging conditions, making it suitable for larger parts that require durability.

- Corrosion Resistance: It has good corrosion resistance in a variety of environments, including marine and chemical processing conditions.

- Formability: In the annealed state, 17-4PH plate is relatively formable, allowing it to be shaped into a variety of components.

- Consistent Thickness: The sheets offer uniform thickness and flatness, making them ideal for structural applications where precision is critical.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

2B Surface

2D Surface

BA Surface

6K Surface

8K Surface

HL Surface

NO.1 Surface

NO.4 Surface

Embossed Surface

Packing

Packing

Proper packaging is crucial to ensuring that your stainless steel arrives in perfect condition. We take every step to make sure your order is protected throughout its journey:

- Sturdy wooden pallets: Our bars and plates are securely packed on sturdy wooden pallets to prevent any movement during transportation, ensuring safe arrival.

- Waterproof packaging: To protect the materials from moisture and corrosion, all items are tightly wrapped with waterproof packaging materials.

- Customized protective layers: We add cushioning and protective layers according to the size and weight of the items, ensuring they remain scratch-free and in perfect condition.

- Clear labeling: Each package is clearly labeled with detailed product information, including grade, size and heat treatment conditions, for easy identification upon delivery.

- Export packaging: Our packaging meets international export standards, ensuring easy customs clearance and delivery anywhere in the world.

Why Choose Us

Why Choose Us

Here’s why we’re your best choice for quality materials and exceptional service:

- High-quality materials: We offer premium stainless steel that ensures exceptional strength, durability, and corrosion resistance for your most demanding applications.

- Customized options: Whether you require a specific size, finish, or heat treatment, we customize our bars and plates to your exact specifications.

- Precision machining: Our advanced manufacturing techniques ensure precise cutting, machining, and fabrication, ensuring your components meet the tightest tolerances.

- Competitive pricing: We offer competitive pricing without compromising quality, ensuring you get the best value for your project.

- Fast delivery: With a streamlined supply chain and efficient logistics, we ensure timely delivery to keep your project on schedule.

- Expert support: Our team of experts is ready to provide technical guidance, from material selection to post-delivery assistance, ensuring you get the right solution for your needs.