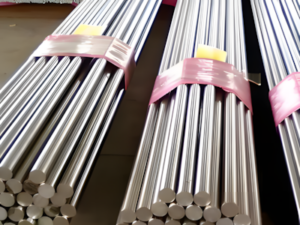

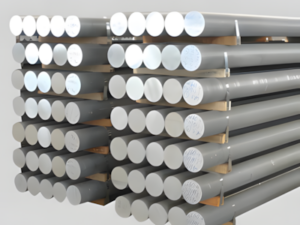

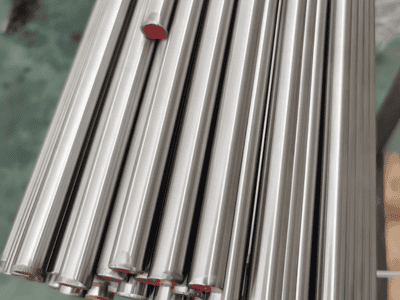

We precision manufacture 316L rods suitable for various industries such as machinery, petrochemical, shipbuilding, metal kitchenware, etc., and process, adjust the size and perform surface treatment according to your needs.

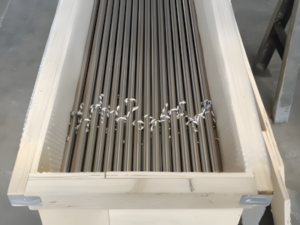

Our products: 316L annealed rod, 1.4404 milling rod, 316L TIG Welding Rod, SUS316L Rod for Various Shaft, Round/Square/Hexagonal Rod, Threaded Rod, Coiled Rod, etc.

| Standard | ASTM A276, ASTM A479/A479M, EN 10088-3, ISO 683-13, JIS G4303 |

|---|---|

| Grade | 00Cr17Ni14Mo2, 0Cr18Ni12Mo2Ti, 1.4404, SUS316L, X2CrNiMo17-12-2 |

| Length | 3 m-6 m (10-20 ft), Customized |

| Diameter | 1 mm-200 mm (0.04-8 in), Customized |

| Shape | Customized, Flat, Hexagonal, Rectangular, Round, Square |

| Surface Finish | 2B, BA, Black, Brushed, Customized, No.1, No.4, Polished |

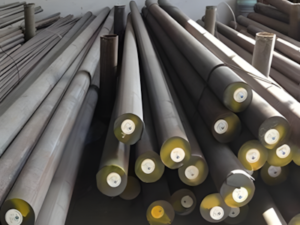

| Technique | Cold Drawn, Cold Rolled, Hot Rolled |

| Form | 316L Bar, 316L Rod in various shapes, Annealed Rod, Coiled Rod, Cold Drawn Rod, Customized, Polished Rod & Bar, Threaded Rod, TIG Welding Rod |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

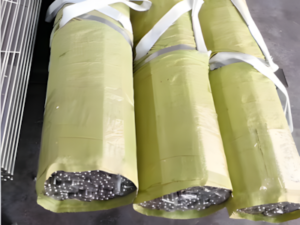

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Canada, Philippines, Australia, India, United Kingdom, Korea, Malaysia, Russian Federation, Germany, Singapore, United Arab Emirates, Brazil, Hong Kong, Indonesia, France, New Zealand, Norway, Pakistan, South Africa, Spain, Egypt, Italy, Mexico, Taiwan, Vietnam, etc.

|

| Carbon (C) | Silicon (Si) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) |

|---|---|---|---|---|---|---|---|---|

| ≤ 0.03 | ≤ 0.75 | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 16.0 – 18.0 | 10.0 – 14.0 | 2.0 – 3.0 | ≤ 0.10 |

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 485 – 620 MPa | 70 – 90 ksi |

| Yield Strength | ≥ 170 MPa | ≥ 25 ksi |

| Vickers Hardness | 152 HV | 152 HV |

| Brinell Hardness | 146 – 217 HB | 146 – 217 HB |

| Rockwell Hardness | 79 HRB | 79 HRB |

| Elongation | ≥ 40% | ≥ 40% |

| Elastic Modulus | 193 – 200 GPa | 28 – 29 Mpsi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info