304L Stainless Steel Round Bar | Rod

304L Stainless Steel Round Bar | Rod

SteelPRO Group is a leading manufacturer and supplier of 304 Stainless Steel Round Bars & Rods in China. We provide:

ASTM 276 304L round bar/rod, UNS S30403 round bar/rod, 1.4307 round bar/rod, 304L stainless steel hot rolled round bar/rod, 304L stainless steel cold drawn round bar/rod, 304L round/square/flat bar, 304L round/square/flat rod, 304 stainless steel threaded rod, 304 stainless steel welding rod, 304 stainless steel filler rod, 304 stainless steel tig rod, etc.

| Standard | ASTM A276, ASTM A479, EN 10088-3 |

|---|---|

| Grade | 1.4307, SUS304L, UNS S30403 |

| Length | Customized, Rod: 3m – 6m (10' – 20'), Round Bar: 3m – 6m (10' – 20') |

| Diameter | Customized, Rod: 3mm – 100mm (0.12'' – 4''), Round Bar: 6mm – 500mm (0.25'' – 20'') |

| Shape | Customized, Flat, Hexagonal, Oval, Rectangular, Round, Square, Triangular |

| Surface Finish | Bright Annealed, Brushed, Customized, Matte, Mirror, Passivated, Pickled, Polished, Sandblasted, Satin |

| Technique | Annealing, Cold Drawing, Cutting, Hot Rolling, Machining, Polishing, Welding |

| Form | Annealed Round Bar/Rod, Cold Drawn Round Bar/Rod, Filler Rod, Forged Round Bar/Rod, Ground Rod/Round Bar, Hot Rolled Round Bar/Rod, Threaded Rod/Round Bar, TIG Rod, Welding Rod |

304L Stainless Steel Round Bar | Rod

304L Stainless Steel Round Bar | Rod

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, United Kingdom, India, Korea, Australia, Russian Federation, Canada, Philippines, Brazil, South Africa, Vietnam, Turkey, Malaysia, France, Hong Kong, Taiwan, Singapore, Germany, Japan, Netherlands, Argentina, Mexico, Indonesia, etc.

|

Chemical Composition

Chemical Composition

| Element | Chromium, Cr | Nickel, Ni | Manganese, Mn | Silicon, Si | Carbon, C | Phosphorus, P | Sulfur, S | Nitrogen, N | Iron, Fe |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 18.0-20.0 | 8.0-12.0 | ≤ 2.00 | ≤ 0.75 | ≤ 0.030 | ≤ 0.045 | ≤ 0.030 | ≤ 0.10 | Balance |

Mechanical Properties

Mechanical Properties

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength (0% cold-worked) | 564 MPa | 81.8 ksi |

| Yield Strength (0% cold-worked) | 210 MPa | 30.5 ksi |

| Brinell Hardness (HB) | – | – |

| Rockwell Hardness (HRB) | 82 | 82 |

| Vickers Hardness (HV) | 159 | 159 |

| Elongation at Break (In 50mm/2”) | 58 % | 58 % |

| Young’s Modulus | 193 – 200 GPa | 28.0 – 29.0 Msi |

Heat Treatment

Heat Treatment

Common heat treatment processes of 304 round bars & rods:

- Normalizing

- Not Applicable

- Reason: 304L is austenitic, and normalizing doesn’t benefit it.

- Annealing

- Temperature: 1010°C – 1120°C

- Process: Heat, then cool slowly to relieve stress and improve ductility.

- Quenching

- Not Recommended

- Reason: 304L cannot harden with quenching due to its austenitic structure.

- Tempering

- Not Applicable

- Reason: Tempering is used after quenching, which doesn’t apply to 304L.

Characteristics

Characteristics

- High corrosion resistance in various environments, including industrial settings.

- Low carbon content reduces the risk of carbide precipitation during welding.

- Strong mechanical properties ensure reliability in load-bearing applications.

- Suitable for both high and low-temperature applications due to its stability.

- Easy to machine and fabricate into different shapes and sizes.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT & Hardness Testing

UT & Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

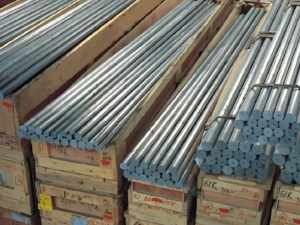

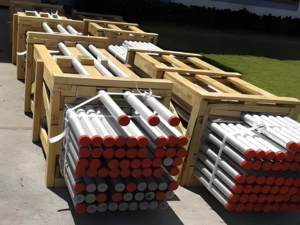

Packing

Packing

At SteelPRO Group, we understand the importance of delivering your goods in pristine condition. That’s why we prioritize robust packing solutions to prevent any damage before your shipment arrives. We offer a range of packing methods and customization options to meet your specific needs. Trust us to handle your products with the utmost care and professionalism.

We provide the following packing options (but not limited to these) based on different conditions:

- Metal Strapping

- Wooden Crates

- Wooden Pallets

- Plastic Wrapping

- Hexagonal Bundling

- Cardboard Tubes

- PVC Coating

- Hexagonal Bundles

- Shrink Wrapping

- Custom Packaging

Why Choose Us

Why Choose Us

SteelPRO Group is a leading manufacturer and solutions provider of specialty steel. We are dedicated to delivering tailored, high-quality solutions across diverse industries. With a commitment to 100% quality assurance, we partner with our clients for mutual growth and success. Trust us to provide the expertise and reliability you need for your critical applications.

Choose us as your trusted partner, and you will get:

- 17+ Years of Manufacturing Experience

- 1M+ Tons Annual Capacity

- 100% Quality Promise

- Factory Direct Sales Price

- Complete Specifications & Ample Storage

- Prompt Delivery

- Customized Solutions