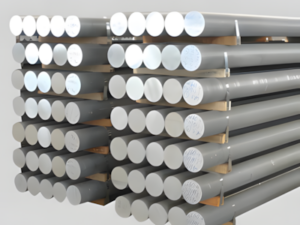

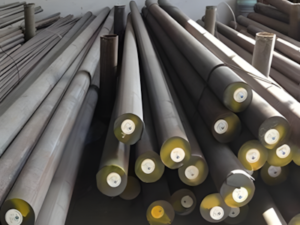

316 Stainless Steel Round Bar

316 Stainless Steel Round Bar

SteelPRO Group is a reliable supplier of 316 Stainless Steel Round Bar from China:

We have 316 hot rolled round bars, 316 cold drawn round bars, 316 seamless round bars, 316 welded round bars, 316 stainless steel flat bar, 316 stainless steel hex bar, 316 stainless steel hex bar, 316 stainless steel square bar, 316 stainless steel angle bar, 316 stainless steel square bar. We provide customizable processing services: cutting, grinding, polishing, heat treatment, surface treatment, bending, drilling, welding, machining, threading, and stamping.

| Standard | ASTM A276 |

|---|---|

| Grade | 0Cr17Ni12Mo2, SUS316, X5CrNiMo17-12-2 |

| Length | 6000 mm (236.22 in) to 12000 mm (472.44 in), Customized |

| Diameter | 5 mm (0.19 in) to 500 mm (19.68 in), Customized |

| Surface Finish | Acid Cleaned, Annealed, Bright, Hairline, Matt, Mirror, Pickled, Polished, Sandblasted, Satin |

| Technique | Annealed, Cold Rolled, Cut to Size, Forged, Ground, Heat Treated, Hot Rolled, Machined, Pickled, Polished |

| Shape | Flat, Hexagonal, Octagonal, Oval, Rectangular, Round, Square, Triangular |

| Form | Annealed Round Bar, Cold Drawn Round Bar, Hot Rolled Round Bar, Pickled Round Bar, Polished Round Bar |

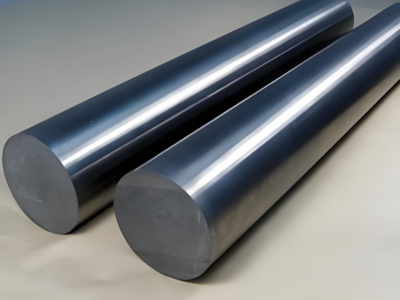

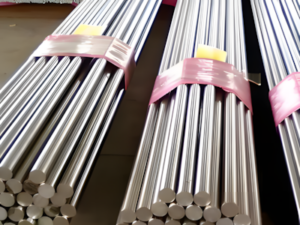

316 Stainless Steel Round Bar

316 Stainless Steel Round Bar

Business Terms

Business Terms

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Canada, Australia, Nigeria, Philippines, Germany, Russian Federation, South Africa, Turkey, Afghanistan, Albania, Algeria, American Samoa, Andorra, Angola, Anguilla, Antigua And Barbuda, Argentina, Armenia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Bosnia And Herzegovina, Botswana, Brazil, Brunei Darussalam, Bulgaria, Burkina Faso, Burundi, etc.

|

Chemical Compositions

Chemical Compositions

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|---|

| Percentage | 0.08% max | 2.00% max | 0.045% max | 0.030% max | 1.00% max | 16.00-18.00% | 10.00-14.00% | 2.00-3.00% | 0.10% max | Balance |

Mechanical Properties

Mechanical Properties

| Properties | Metric Unit | Imperial Unit |

|---|---|---|

| Tensile Strength | 515 – 720 MPa | 74,700 – 104,400 psi |

| Yield Strength | 205 MPa min | 29,700 psi min |

| Vickers Hardness | 152 – 248 HV | 152 – 248 HV |

| Brinell Hardness | 146 – 217 HB | 146 – 217 HB |

| Rockwell Hardness | B79 – B95 | B79 – B95 |

| Elongation | 40% min | 40% min |

| Elastic Modulus | 193 – 200 GPa | 28,000 – 29,000 ksi |

Heat Treatment

Heat Treatment

- Solution Annealing

- Temperature: 1010°C to 1120°C (1850°F to 2050°F)

- Process: Heated, then quenched rapidly in water

- Stress Relieving

- Temperature: 450°C to 600°C (840°F to 1110°F)

- Process: Heated and held, then cooled in air

- Quenching

- Temperature: 1010°C to 1120°C (1850°F to 2050°F)

- Process: Water quenching after heating to the solution annealing temperature

- Tempering/Hardening

- Less common

- Not typically required or applicable for 316 stainless steel

Characteristic

Characteristic

Here are the characteristics of 316 Stainless Steel Round Bar:

- Corrosion Resistance: Excellent in harsh environments.

- High Strength: Strong under high stress.

- Heat Resistance: Performs well at elevated temperatures.

- Weldability: Easily welded with most methods.

- Durability: Long-lasting and tough.

- Machinability: Moderate to good machinability.

- Non-Magnetic: Typically non-magnetic in annealed form.

- Low Maintenance: Requires minimal upkeep.

Our Service

Our Service

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing

UT And Hardness Testing

UT And Hardness Testing Info

Surface Finish

Surface Finish

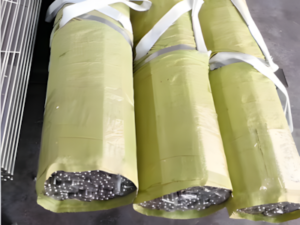

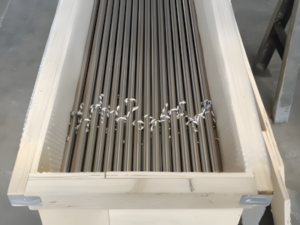

Packing

Packing

- Durable Packaging Materials: We use strong wooden crates and steel straps to protect 316 stainless steel round bars.

- Moisture Protection: Each bar is wrapped with moisture-proof materials to prevent rust during transit.

- Customized Packing: We adjust packaging to fit customer needs, saving space and reducing costs.

- International Standards: Our packing meets ISO and global standards for safe transportation.

Why Choose Us

Why Choose Us

-

Ample Stock: Large inventory with custom services. Includes special sizes, surface finishes, and processing services.

-

Global Coverage: A global supply chain and service network to meet the needs of international customers.

-

Quick Response: Fast response within 24 hours for quotations, and professional technical support and after-sales service. Lifetime warranty.

-

Compliance and Certification: Products meet ASTM standards, with SGS or TUV certificates. Each package is labeled for easy identification.

-

Diverse Shipping Options: Choose from FOB, CFR, and CIF shipping methods. Select the best terms to optimize costs and ensure safety.