SteelPRO Group is a reliable 316 Stainless Steel Sheet supplier from China:

We have 316 hot-rolled sheets, 316 cold-rolled sheets, 316 perforated sheets, 316 polished sheets, 316 welded sheets, 316 seamless sheets, 316 annealed sheets, and 316 pickled sheets. We offer custom processing options such as cutting, bending, welding, polishing, perforating, annealing, pickling, shearing, drilling, and laser cutting.

| Standard | ASTM A240 |

|---|---|

| Grade | 0Cr17Ni12Mo2, 1.4401, SUS316 |

| Length | 6000 mm (236.22 in) to 12000 mm (472.44 in), Customized |

| Width | 1000 mm (39.37 in) to 2000 mm (78.74 in), Customized |

| Thickness | 0.3 mm (0.012 in) to 100 mm (3.937 in), Customized |

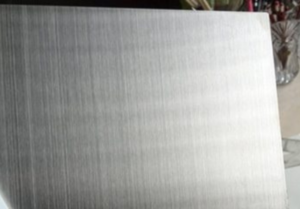

| Surface Finish | 2B, 8K, BA, Brushed, HL, Mirror, No.1, No.4, PVC Coated, SB |

| Technique | Bending, Cold Rolling, Cutting, Hot Rolling, Punching, Shearing, Stamping, Welding |

| Form | Coated sheet, Embossed sheet, Expanded sheet, Flat sheet, Foil, Perforated sheet, Plate, Polished sheet, Rolled sheet, Textured sheet |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United Kingdom, United States, Australia, India, Korea, Russian Federation, Canada, Brazil, Philippines, South Africa, Malaysia, Taiwan, Romania, Indonesia, Germany, Turkey, Vietnam, etc.

|

| Element | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Nitrogen (N) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|---|

| Percentage | 0.08% max | 2.00% max | 0.75% max | 0.045% max | 0.030% max | 16.00-18.00% | 10.00-14.00% | 2.00-3.00% | 0.10% max | Balance |

| Properties | Metric (MPa) | Imperial (ksi) |

|---|---|---|

| Tensile Strength | 515 – 720 MPa | 75 – 104.4 ksi |

| Yield Strength | 205 MPa | 30 ksi |

| Vickers Hardness | 150 – 230 HV | 150 – 230 HV |

| Brinell Hardness | 146 – 217 HB | 146 – 217 HB |

| Rockwell Hardness | 80 HRB max | 80 HRB max |

| Elongation | 40% | 40% |

| Elastic Modulus | 193 – 200 GPa | 28 – 29 x10^3 ksi |

Here are the characteristics of 316 Stainless Steel Sheet:

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info