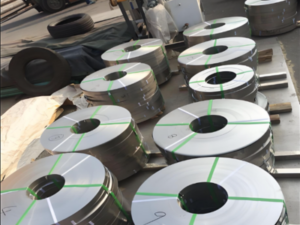

SteelPRO Group is a leading manufacturer and supplier of 304 Stainless Steel Strips in China. We provide:

1.4301 stainless steel strip, ASTM A240 304 stainless steel strip, 304 stainless steel hot rolled strip, 304 stainless steel cold rolled strip, 304 stainless steel galvanized strip, 304 stainless steel pickled strip, 304 stainless steel slit strip, 304 stainless steel brushed/polished/mirror/matte strip, 304 stainless steel mill strip, 304 stainless steel sheared strip, 304 stainless steel plate, 304 stainless steel sheet, 304 stainless steel coil, 304 stainless steel foil, etc.

| Standard | ASTM A240 / A240M, EN 10088-2 |

|---|---|

| Grade | 06Cr19Ni10, 1.4301, SUS 304, UNS S30400 |

| Thickness | 0.1 mm – 3.0 mm (0.004'' – 0.12''), Customized |

| Width | 5 mm – 800 mm (0.2'' – 31.5''), Customized |

| Inner Diameter | 200 mm – 610 mm (7.9'' – 24''), Customized |

| Edge | Deburred Edge, Mill Edge, Round Edge, Slit Edge |

| Technique | Annealing, Coating, Cold Rolling, Hot Rolling |

| Surface Finish | 2B, 2D, 8K, BA, Brush, Checkered, Customized, Embossed, Etching, Hair Line, Mirror, No.1, No.4, No.8, Sand Blast |

| Form | Plates, Sheets, Coils, Foils, Cut-to-Length Strips, Slit Strips, Edge Conditioned Strips, Flat Strips, Brushed Strip, Polished Strip, Mirror Strip, Matted Strip, Bead Blasted Strip, Embossed Strip, Etched Strip, Customized |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, Canada, India, Philippines, Australia, Russian Federation, South Africa, Armenia, Brazil, Hong Kong, Indonesia, Korea, Malaysia, New Zealand, Singapore, etc.

|

| Element | Chromium, Cr | Nickel, Ni | Carbon, C | Manganese, Mn | Silicon, Si | Phosphorus, P | Sulfur, S | Nitrogen, N | Iron, Fe |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 18.0-20.0 | 8.0-10.5 | ≤0.08 | ≤2.0 | ≤1.0 | ≤0.045 | ≤0.03 | ≤0.10 | Balance |

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 505 MPa | 73.2 ksi |

| Yield Strength (at 0.2% offset) | 215 MPa | 31.2 ksi |

| Brinell Hardness | 123 | 123 |

| Rockwell Hardness | 70 | 70 |

| Vickers Hardness | 129 | 129 |

| Elongation at Break (in 50 mm) | 70% | 70% |

| Young’s Modulus | 193-200 GPa | 28-29 msi |

Common heat treatment processes of 304 stainless steel strip:

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

At SteelPRO Group, we understand the importance of delivering your goods in pristine condition. That’s why we prioritize robust packing solutions to prevent any damage before your shipment arrives. We offer a range of packing methods and customization options to meet your specific needs. Trust us to handle your products with the utmost care and professionalism.

SteelPRO Group is a leading manufacturer and solutions provider of specialty steel. We are dedicated to delivering tailored, high-quality solutions across diverse industries. With a commitment to 100% quality assurance, we partner with our clients for mutual growth and success. Trust us to provide the expertise and reliability you need for your critical applications.

Choose us as your trusted partner, and you will get: