We are a 303 stainless steel supplier and manufacturer, committed to providing high-quality materials to your exact specifications. We provide a wide range of services, including custom cutting, precision manufacturing, fast delivery, technical support.

Our Product: 303 seamless tubing, 303 welded pipe, 303 cold drawn tube, X8CrNiS18-9 hot rolled tubing, 303 round tubing, 1.4305 square tubing, rectangular tubing, U-bend tubing, 303 polished tubing, SUS303 precision tubing.

| Standard | ASTM A213, ASTM A511, ASTM A554 |

|---|---|

| Grade | 1.4305, 303S31, SUS303, X8CrNiS18-9 |

| Length | 1000 mm-6000 mm (39.37-236.22 in), Customized |

| OD | 6 mm-350 mm (0.24-13.78 in), Customized |

| WT | 0.5 mm-10 mm (0.02-0.4 in), Customized |

| Shape | Coiled Tube, Customized, Flat, Hexagonal, Oval, Rectangular, Round, Square, U-bend Tube |

| Surface Finish | 2B, BA, Brushed, etc., No.4, No.8, Pickling, Polishing |

| Form | Capillary Tube, Cold Drawn Tube, etc., Hot Rolled Tube, Pipe, Polished Tube, Precision Tube, Round Tube, Seamless Tube, Square Tube, Tubing, Welded Tube |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

United States, India, United Kingdom, Canada, Australia, Philippines, Malaysia, Nepal, Pakistan, Brazil, France, Ireland, Mexico, Netherlands, Russian Federation, Singapore, South Africa, Bangladesh, Ghana, Hong Kong, Indonesia, Italy, Korea, New Zealand, Oman, Qatar, Spain, Sri Lanka, Thailand, United Arab Emirates, Vietnam, Zambia, Zimbabwe, etc.

|

| Element | Chromium (Cr) | Nickel (Ni) | Carbon (C) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|---|

| Composition (%) | 17.0 – 19.0 | 8.0 – 10.0 | ≤ 0.15 | ≤ 2.0 | ≤ 1.0 | ≤ 0.20 | 0.15 – 0.35 |

| Mechanical Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Tensile Strength | 500 – 750 MPa | 72.5 – 108.7 ksi |

| Yield Strength | 275 – 450 MPa | 40 – 65 ksi |

| Brinell Hardness (HB) | 180 – 200 HB | 180 – 200 HB |

| Rockwell Hardness (HRB) | 78 – 82 HRB | 78 – 82 HRB |

| Vickers Hardness (HV) | 200 – 220 HV | 200 – 220 HV |

| Elongation | 20% – 40% | 20% – 40% |

| Elastic Modulus | 193 GPa | 28 x 10^3 ksi |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

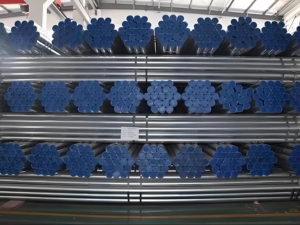

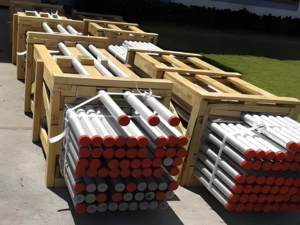

We ensure your 303 stainless steel tubes are delivered in perfect condition. With our premium packaging solutions, your 303 stainless steel tubes will arrive ready for use, no matter the destination.

At SteelPRO Group, we are committed to providing top quality 303 stainless steel tubes that meet your needs.