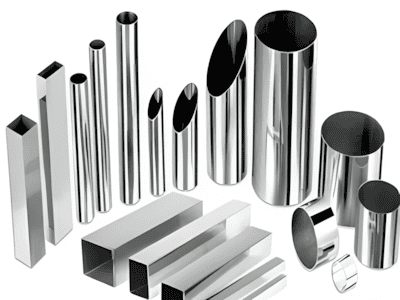

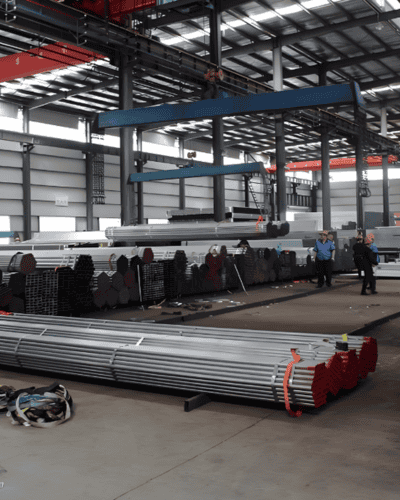

We are a manufacturer, exporter and supplier of a wide range of stainless steel 309 tubing and other steel products worldwide. We offer customization to suit your needs in different sizes, finishes and surface treatments.

Our Product: 309 Tubing, 309 Mechanical Tubing, 1.4828 Coiled Tubes, X15CrNiSi20-12 U-Bend Tubes, 309 Square and Rectangular Tubes, Capillary Tubes, Boiler Tubes, Instrumentation Tubing, Heat Exchanger Tubes, Wholesale welded Tubes, Wholesale seamless Tubes, 309 Pipe.

| Standard | ASTM A213, ASTM A269, ASTM A312, EN 10216-5, GB/T 14976 |

|---|---|

| Grade | 1Cr20Ni14Si2, SUH309, X15CrNiSi20-12 |

| Surface Finish | 2B, BA, Customized, No. 1, NO. 4, No.8, Polishing |

| Length | 6000mm-12000mm (236.22-472.44 in), Customized |

| OD | 6mm-200mm (0.236-7.87 in), Customized |

| WT | 0.38mm-12.7mm (0.015-0.5 in), Customized |

| Shape | Customized, Hexagonal, Oval, Rectangular, Round, Square |

| Form | Beveled End Tubing, etc., Heat Exchanger Tubes, Pipe, Plain End Tubing, Seamless Pipe, Seamless Tubing, Treaded Tubing, Welded Tubing |

| Terms | Specification |

|---|---|

| Minimum Order Quantity: | 5 Tons |

| Price: | To be negotiated |

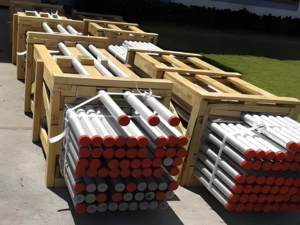

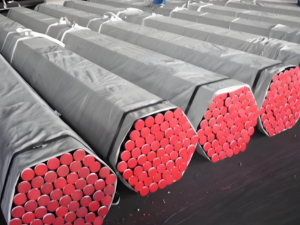

| Packaging Details: |

As Requested

|

| Delivery Time: | Within 7-10 Working Days |

| Payment Terms: | T/T, L/C, Credit Card |

| Supply Ability: | 100000 Tons per month |

| Certification: | RoHS, BIS, SABS, tisi, KS, JIS, ISO9001 |

| Export To: |

UK, United States, Australia, India, Canada, Philippines, Malaysia, New Zealand, Brazil, Korea, Russia, Hong Kong, South Africa, Indonesia, Singapore, Vietnam, Thailand, Turkey, Mexico, Germany, etc.

|

| C | Ni | Si | S | Mn | P | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.20 max | 12.0 – 15.0 | 0.75 max | 0.03 max | 2.00 max | 0.045 max | 22.0 – 24.0 | – |

| Property | Imperial Units | Metric Units |

|---|---|---|

| Tensile Strength | 70 – 90 ksi | 480 – 620 MPa |

| Yield Strength | 35 – 45 ksi | 240 – 310 MPa |

| Vickers Hardness | 150 – 200 HV | 150 – 200 HV |

| Brinell Hardness | 140 – 160 HB | 140 – 160 HB |

| Rockwell Hardness | HRB 80 – 95 | HRB 80 – 95 |

| Elongation | 30 – 45% | 30 – 45% |

| Elastic Modulus | 28 – 30 x 10^6 psi | 190 – 210 GPa |

1.Welding

2.Metal Fabrication

3.CNC Machining

4.Lathe

5.Forming

6.OEM/ODM

7.Quenching

8.Tempering

UT And Hardness Testing Info

Our packaging is designed to provide maximum protection and minimize the risk of damage during shipping.

SteelPRO Group is committed to being your trusted partner for high-quality stainless steel materials. We stand out in the industry with our commitment to excellence and customer-centricity.